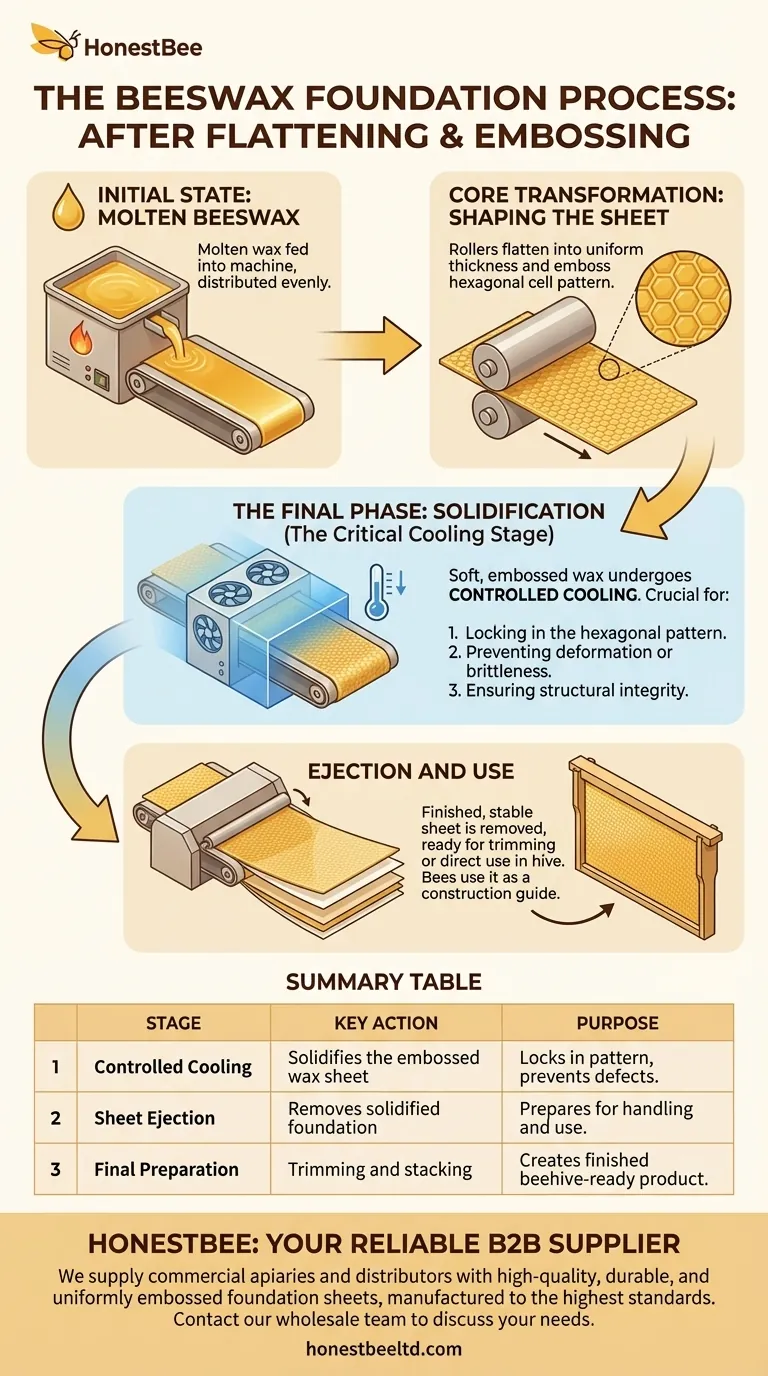

In short, once a beeswax sheet is flattened and embossed, it undergoes a critical cooling phase to solidify the hexagonal pattern. After it has hardened, the finished foundation sheet is ejected from the machine, ready for final trimming or direct use in a beehive.

The final steps of the beeswax foundation process—cooling and removal—are not merely mechanical; they are essential for transforming molten wax into the stable, precisely patterned structure that guides a honeybee colony's construction.

The Journey from Liquid Wax to Hive Foundation

To understand what happens after embossing, it's helpful to view the entire manufacturing sequence. The final steps are what lock in the quality and usability of the finished product.

The Initial State: Molten Beeswax

The process begins by feeding clean, molten beeswax into the foundation machine. The system ensures this liquid wax is distributed evenly, typically onto a flat surface or a continuously moving belt.

The Core Transformation: Shaping the Sheet

This liquid wax is then passed through rollers that perform two simultaneous actions. First, they flatten the wax into a sheet of uniform thickness. Second, they emboss it with the characteristic hexagonal cell pattern that bees use as a guide.

The Final Phase: Solidification

This is the stage your question addresses. Once the sheet is embossed, it must be cooled in a controlled manner. This step is crucial because it allows the soft, pliable wax to solidify, permanently setting the embossed pattern. Without proper cooling, the delicate hexagonal imprints would deform.

Ejection and Use

Finally, the machine removes or ejects the now-solid and cooled foundation sheet. At this point, it is a finished product, stable enough to be handled, cut to specific frame sizes, and placed into a beehive.

Understanding the Critical Factors

The success of the final product depends entirely on how well these last steps are managed. The transition from a hot, embossed sheet to a cool, solid one is delicate.

The Role of Controlled Cooling

The rate of cooling is a significant factor. If the sheet cools too quickly, it can become brittle and crack. If it cools too slowly, the embossed pattern may not set properly, leading to imperfections.

Ensuring Structural Integrity

The sole purpose of this process is to create a "foundation" that gives the bees a head start. The precision of the embossing, combined with the stability provided by proper cooling, results in a sheet that bees will readily accept and build upon.

From Machine to Hive

Once ejected, sheets are often stacked with paper separators to prevent sticking. They may be sold as-is or cut by the beekeeper to fit the specific dimensions of their hive frames.

Making the Right Choice for Your Goal

Understanding this process allows you to better evaluate the final product, whether you are making it or buying it.

- If your primary focus is purchasing high-quality foundation: Look for sheets with a crisp, uniform hexagonal pattern and a consistent thickness, as this indicates a well-controlled manufacturing and cooling process.

- If your primary focus is operating foundation machinery: Pay close attention to the cooling system and sheet removal mechanism, as calibrating these is key to preventing defects and maximizing output quality.

Ultimately, this carefully controlled process ensures the creation of a perfect structural guide for the honeybee colony.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| Controlled Cooling | Solidifies the embossed wax sheet | Locks in the hexagonal pattern, prevents brittleness or deformation |

| Sheet Ejection | Removes the solidified foundation from the machine | Prepares the sheet for final handling and use |

| Final Preparation | Trimming and stacking with separators | Creates a finished product ready for the beehive |

Need a reliable supply of high-quality beeswax foundation? The precision of the final cooling and ejection process is critical for producing foundations that bees readily accept. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, uniformly embossed foundation sheets, manufactured to the highest standards. Let us support your operation's success. Contact our wholesale team today to discuss your needs.

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- How is beeswax foundation installed and reinforced in a frame? Master Durable Comb Setup for Your Apiary

- How do beehive frames and beeswax foundation sheets contribute to honey harvesting? Boost Yield and Hygiene

- Why is beeswax foundation considered an essential consumable? Maximize Hive Productivity and Honey Yields

- What are the advantages of using beeswax foundation in a beehive? Boost Honey Yields and Hive Purity

- What are the benefits of high-quality beeswax foundation sheets? Optimize Your Large-Scale Apiary Management Today