A fully automatic wax foundation machine is an industrial tool used to mass-produce wax foundation sheets for beehives. These sheets are thin, precisely milled pieces of beeswax imprinted with the hexagonal pattern of a honeycomb, which serve as a critical guide for bees to build straight and uniform combs.

The core purpose of this machine is to bring structure and efficiency to the beehive. By providing a perfect "blueprint," it saves the bees significant energy and gives the beekeeper predictable, manageable combs, which is fundamental to modern, large-scale beekeeping and honey production.

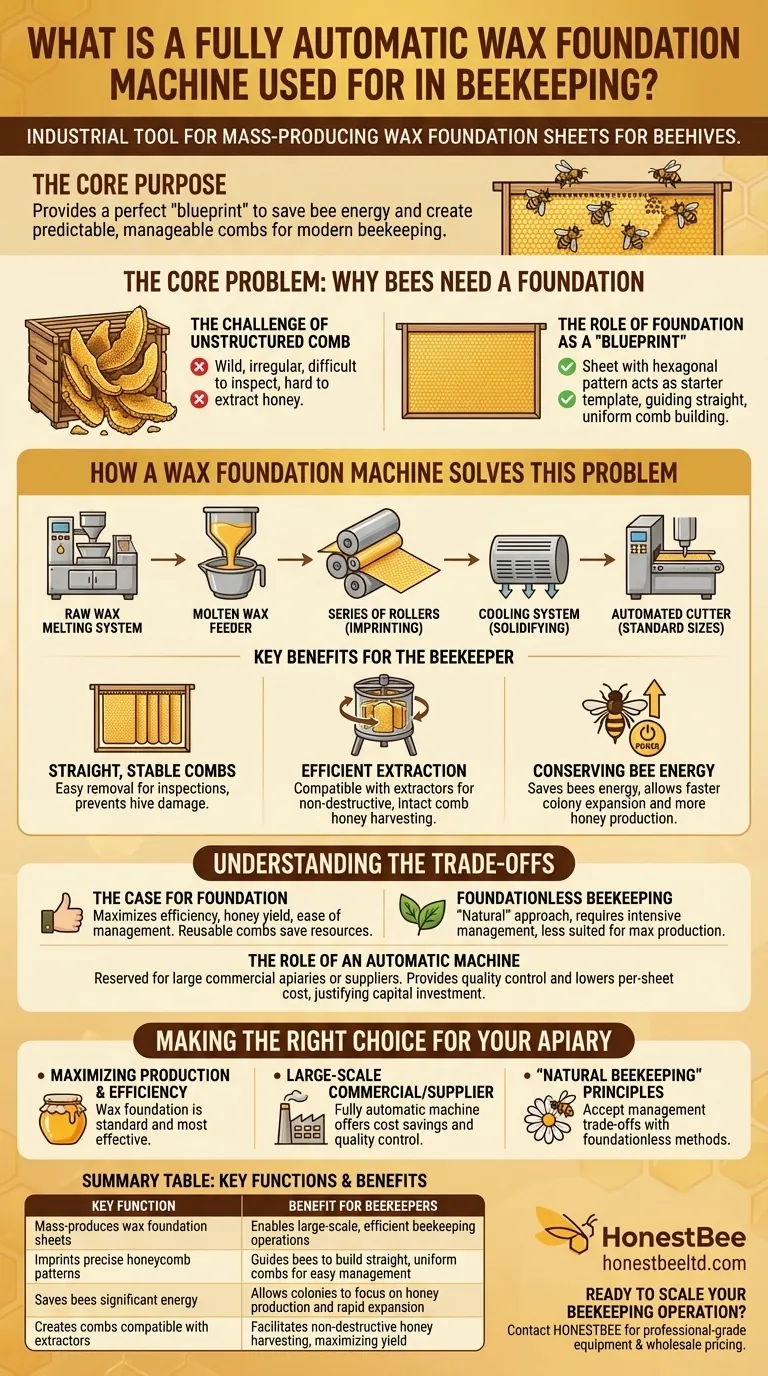

The Core Problem: Why Bees Need a Foundation

The Challenge of Unstructured Comb

In a natural state, bees build their own wax comb. While perfectly functional for the colony, this "wild" comb is often irregular, curved, and not aligned with the beekeeper's rectangular frames.

This creates significant problems for hive management. Irregular combs are difficult to remove for inspection, can break easily, and make honey extraction nearly impossible without destroying the entire comb structure.

The Role of Foundation as a "Blueprint"

Wax foundation solves this problem. It's a sheet of pure beeswax with the hexagonal cell pattern embossed onto its surface, acting as a starter template.

When placed in a frame, the bees immediately recognize the pattern and begin drawing out the cell walls. This guides them to build perfectly straight, uniform combs that fit neatly within the frame.

How a Wax Foundation Machine Solves This Problem

From Raw Wax to Structured Sheets

A fully automatic machine streamlines the entire production process. It typically starts with a system that melts raw beeswax to the perfect temperature.

This molten wax is then fed through a series of rollers that form it into a continuous, thin sheet. These rollers are also responsible for imprinting the precise honeycomb pattern onto the wax. Finally, a cooling system solidifies the sheet before an automated cutter slices it into standard sizes.

Key Benefits for the Beekeeper

Using foundation sheets produced by these machines provides several major advantages for hive management and productivity.

It results in straight, stable combs that are easy to remove for inspections without damaging the hive's structure. This uniformity is also essential for using a centrifugal extractor, which spins honey out of the combs while leaving them intact.

Conserving Bee Energy

Building wax comb is an energy-intensive process for bees. By providing a foundation, the beekeeper gives the colony a massive head start.

The bees can focus their energy on drawing out the cells and filling them with honey, pollen, or brood, rather than constructing the entire comb base from scratch. This allows the colony to expand more rapidly and produce more honey.

Understanding the Trade-offs

The Case for Foundation

For most commercial or large-scale beekeepers, foundation is non-negotiable. It maximizes efficiency, honey yield, and ease of management.

The ability to reuse drawn combs after honey extraction saves the colony immense resources year after year, leading to a stronger and more productive hive. It also helps control the hive's population by encouraging the creation of worker cells over less-desirable drone cells.

Foundationless Beekeeping

Some hobbyists or "natural" beekeepers prefer foundationless frames, allowing bees to build their comb entirely on their own. This is seen as a more natural approach.

However, this method requires more intensive management to prevent irregular comb and can make honey extraction more destructive. It is generally not suited for operations focused on maximizing honey production.

The Role of an Automatic Machine

A beekeeper with a few hives will simply buy foundation sheets. An investment in a fully automatic wax foundation machine is reserved for large commercial apiaries or beekeeping suppliers.

For these operations, the machine provides complete control over the quality of the beeswax used and dramatically lowers the per-sheet cost, justifying the significant capital investment.

Making the Right Choice for Your Apiary

The decision to use foundation—or even invest in a machine to make it—depends entirely on your beekeeping goals.

- If your primary focus is maximizing honey production and operational efficiency: Using wax foundation is the standard and most effective method.

- If you are a large-scale commercial operator or supplier: A fully automatic machine offers long-term cost savings and complete quality control over your foundation supply.

- If your primary focus is on "natural beekeeping" principles: You may prefer foundationless beekeeping, but you must accept the trade-offs in management complexity and extraction.

Ultimately, a wax foundation machine is a tool of scale, designed to solve a fundamental challenge in the partnership between the bee and the beekeeper.

Summary Table:

| Key Function | Benefit for Beekeepers |

|---|---|

| Mass-produces wax foundation sheets | Enables large-scale, efficient beekeeping operations |

| Imprints precise honeycomb patterns | Guides bees to build straight, uniform combs for easy management |

| Saves bees significant energy | Allows colonies to focus on honey production and rapid expansion |

| Creates combs compatible with extractors | Facilitates non-destructive honey harvesting, maximizing yield |

Ready to scale your beekeeping operation with professional-grade equipment?

As HONESTBEE, we specialize in supplying durable, high-performance beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. A fully automatic wax foundation machine is a cornerstone of efficient, large-scale honey production.

Let us help you boost your hive productivity and honey yield. Contact our experts today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation