A piston filling machine is a specialized piece of equipment designed to dispense a precise, repeatable volume of product into a container. It operates using a piston-cylinder mechanism, similar to a syringe, to pull a product from a bulk source like a hopper and then push it out through a nozzle. This method is exceptionally effective for a wide range of products, particularly viscous liquids like honey, creams, sauces, and gels.

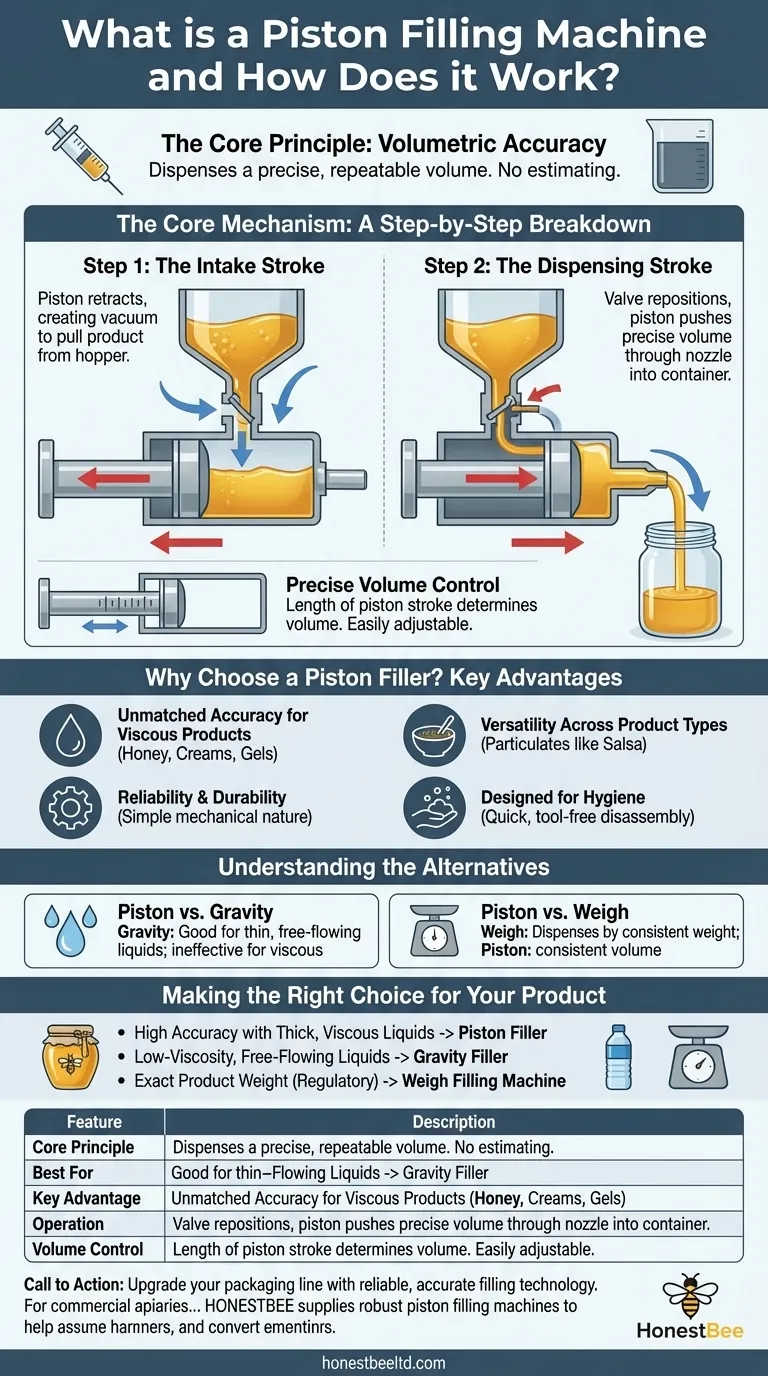

The core principle of a piston filler is volumetric accuracy. It doesn't guess or estimate; it measures and dispenses a consistent volume of product with every cycle, making it the industry standard for products where fill level consistency is critical.

The Core Mechanism: A Step-by-Step Breakdown

A piston filler's operation is a simple, two-part mechanical cycle. Understanding these two strokes is key to understanding the entire machine.

Step 1: The Intake Stroke

The cycle begins with the piston retracting within its cylinder. This backward movement creates a vacuum, which pulls the product from an overhead hopper through a valve and into the cylinder, filling the empty space.

Step 2: The Dispensing Stroke

Once the cylinder is full, the valve system instantly repositions itself. The piston then moves forward, pushing the precisely measured product out of the cylinder and through a nozzle into the waiting container.

Step 3: Precise Volume Control

The amount of product dispensed is determined by the length of the piston's stroke within the cylinder. A longer stroke draws in and pushes out more product, while a shorter stroke dispenses less. This stroke length is easily adjustable, giving operators exact control over fill volumes.

Why Choose a Piston Filler? Key Advantages

The piston filler's design offers distinct advantages for specific applications, making it a reliable workhorse in many packaging lines.

Unmatched Accuracy for Viscous Products

For thick products like honey, pastes, or heavy creams, gravity-based fillers are unreliable. A piston filler uses positive force to move the product, ensuring that the same amount is dispensed every time, regardless of changes in product temperature or viscosity.

Versatility Across Product Types

This technology is not limited to simple liquids. Piston fillers are highly effective for products with large particulates, such as salsas, fruit preserves, or potato salads, which would clog other types of filling machines.

Reliability and Durability

The mechanical nature of a piston filler is straightforward and robust. With fewer complex electronic components controlling the fill, these machines are known for their long-term reliability and ease of maintenance.

Designed for Hygiene

In the food, cosmetic, and pharmaceutical industries, cleanliness is paramount. Most piston fillers are designed for quick, tool-free disassembly, allowing operators to thoroughly clean all product contact parts and prevent cross-contamination.

Understanding the Alternatives and Trade-offs

While powerful, a piston filler isn't the only solution. Knowing how it compares to other technologies helps clarify its specific role.

Piston vs. Gravity Fillers

A gravity filler relies on the natural force of gravity to move a product from a hopper into a container. This works well for thin, free-flowing liquids like water or juice but is completely ineffective for thick, viscous products. The piston filler's mechanical force makes it superior for anything that doesn't flow easily on its own.

Piston vs. Weigh Fillers

A piston filler is a volumetric machine—it dispenses a consistent volume. A weigh filling machine, by contrast, dispenses a consistent weight. While a piston filler provides excellent accuracy, a weigh filler is the correct choice when the exact net weight of the product is the most critical factor for regulatory or cost-control reasons.

Making the Right Choice for Your Product

Selecting the correct filling technology comes down to understanding the nature of your product and your primary production goal.

- If your primary focus is high accuracy with thick, viscous liquids (creams, honey, gels): A piston filler is the industry standard and the most reliable choice.

- If your primary focus is filling low-viscosity, free-flowing liquids (water, juice): A simpler and often faster gravity filler may be a more cost-effective solution.

- If your primary focus is guaranteeing an exact product weight for regulatory or cost reasons: A weigh filling machine is the most direct solution, as it measures by weight, not volume.

Understanding the core principle of volumetric dispensing is the key to selecting the right filling technology for your specific product and production goals.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Volumetric Dispensing (measures by volume) |

| Best For | Viscous liquids, products with particulates (e.g., honey, sauces, creams, salsas) |

| Key Advantage | High accuracy and reliability with thick products |

| Operation | Two-stroke cycle: Intake Stroke (fills cylinder) and Dispensing Stroke (fills container) |

| Volume Control | Adjusted by changing the piston's stroke length |

Upgrade your packaging line with reliable, accurate filling technology.

For commercial apiaries and beekeeping equipment distributors, consistent honey filling is critical for brand reputation and efficiency. HONESTBEE supplies robust piston filling machines and other essential beekeeping supplies through our wholesale-focused operations, helping you scale your production with precision equipment built for durability.

Contact HONESTBEE today to discuss how our piston fillers can enhance your operation's speed and accuracy.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- What is the primary function of industrial-grade honey filling machines in apitherapy? Preserve Purity & Potency

- How does a volume honey filling machine ensure accurate filling? Precision Filling for Maximum Product Value

- How do honey-filling machines optimize the value chain? Boost Throughput and Precision for Commercial Distribution

- Why is the use of professional industrial filling equipment essential for stingless bee honey? Ensure Safety & Value

- What are the primary functions and benefits of using a honey filling machine? Scale Your Production and Ensure Precision

- How does the use of automatic honey-filling equipment enhance operations? Scale Your Commercial Apiary Profitability

- What are the advantages of using automated honey filling equipment? Protect Honey Quality and Physicochemical Integrity

- How does the health of nectar-source plant communities influence the utilization rate of industrial honey-filling machinery?