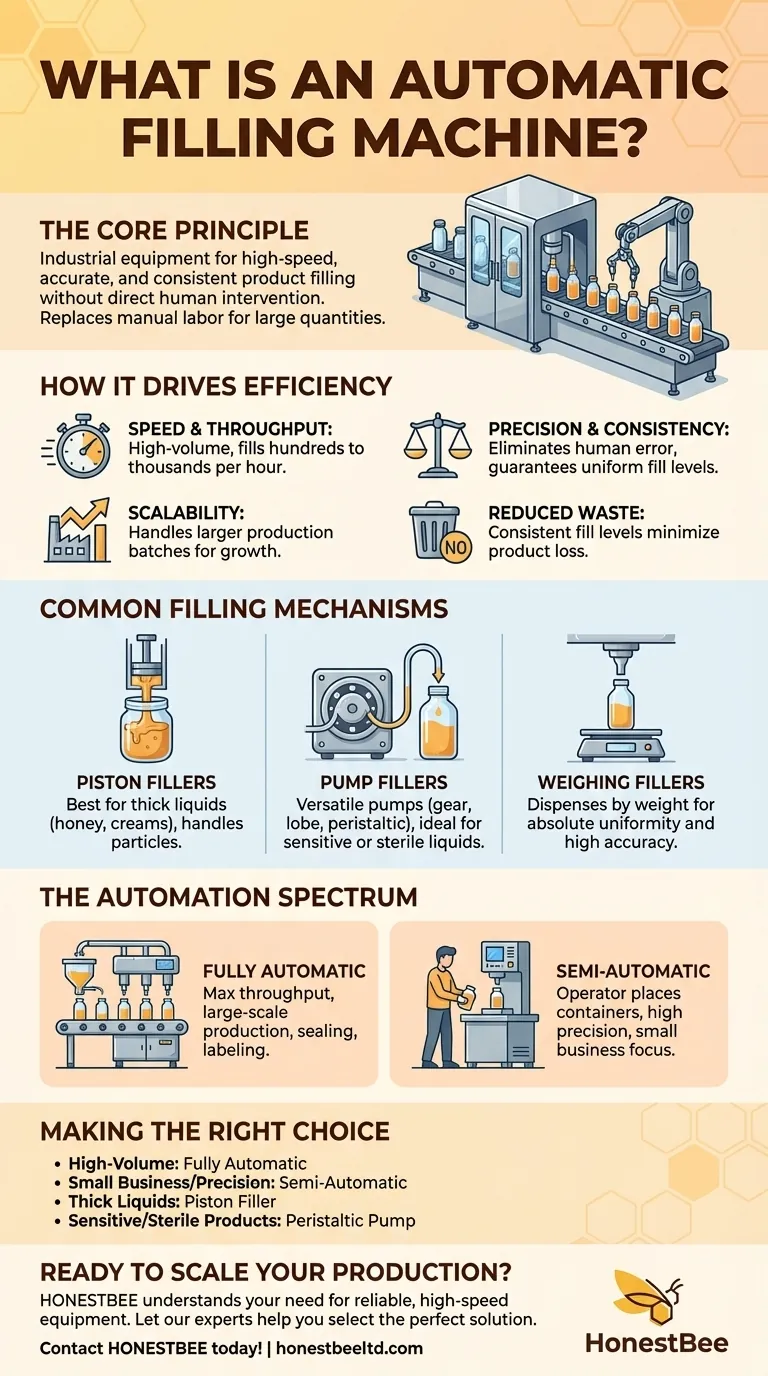

At its core, an automatic filling machine is industrial equipment designed to fill large quantities of containers with a product, typically a liquid, without direct human intervention. The entire process—from measuring the product to dispensing it into the container—is controlled by a pre-programmed system to ensure high speed, accuracy, and consistency across thousands of units.

The fundamental purpose of an automatic filling machine is to replace manual labor with a precise, high-speed mechanical process. This shift enables businesses to scale production, reduce product waste, and guarantee that every container is filled to the exact same level or weight.

How Automatic Filling Machines Drive Efficiency

An automatic filling machine operates as a complete system. It controls the flow of product from a bulk source, measures a precise amount, and dispenses it into containers that are moved along a conveyor.

The Principle of Automated Control

The machine is programmed to manage the entire filling cycle. This control ensures that each container receives the exact same volume or weight of product, eliminating the inconsistencies common in manual processes.

Speed and Throughput

These systems are built for high-volume environments. They can fill hundreds or even thousands of containers per hour, dramatically increasing production capacity compared to any manual or semi-automatic method.

Precision and Consistency

Automation removes human error from the filling equation. This results in highly consistent fill levels, which reduces product waste and ensures customers receive a uniform product every time.

Scalability for Growth

As a business grows, an automatic filler can easily handle larger production batches. This scalability is critical for companies looking to expand their market reach without a proportional increase in labor costs.

Common Filling Mechanisms Explained

Different products require different handling. The mechanism inside the machine is chosen based on the product's viscosity, sensitivity, and whether it contains particles.

Piston Fillers for Viscosity

A piston filler is highly versatile and works by drawing product from a hopper into a cylinder. The piston then pushes the product out through a nozzle into the container. This method is exceptionally effective for thick, dense liquids like honey, creams, or sauces, even those with large particles.

Pump Fillers for Versatility

Pump fillers use various types of pumps—such as gear, lobe, or peristaltic—to move liquid from a tank into containers. Peristaltic pumps are notable because the product only touches a flexible, sterile tube, making them ideal for sensitive, corrosive, or pharmaceutical liquids where sanitation is critical.

Weighing Fillers for Uniformity

A weighing filler, also known as a net weight filler, dispenses product into each container until a specific weight is reached. This method is valued for its high accuracy, ensuring absolute uniformity in the final packaged product.

Understanding the Automation Spectrum

Not all filling operations require the same level of automation. The primary distinction comes down to the degree of manual involvement required.

The Fully Automatic System

A fully automatic machine handles the entire process: container feeding, filling, sealing, and labeling. It is the best solution for large-scale factories where maximizing efficiency and throughput is the primary objective.

The Semi-Automatic Alternative

A semi-automatic machine bridges the gap between manual labor and full automation. It typically requires an operator to place the containers for filling but automates the dispensing process itself. This provides high precision and control, making it an ideal choice for small businesses or those with smaller production runs.

Making the Right Choice for Your Goal

Selecting the correct filling machine depends entirely on your product, production volume, and operational goals.

- If your primary focus is high-volume production: A fully automatic system is the definitive choice for achieving maximum speed and cost-effectiveness.

- If you are a small business needing precision: A semi-automatic machine provides the accuracy of automation without the investment of a fully integrated system.

- If you are filling thick, dense, or particle-heavy liquids: A piston filler is specifically engineered to handle these challenging products reliably.

- If you are handling sensitive, sterile, or corrosive products: A peristaltic pump filler offers superior sanitation and protects the product from contamination.

Ultimately, choosing the right filling technology is a strategic decision that directly impacts your production capacity and product quality.

Summary Table:

| Feature | Fully Automatic | Semi-Automatic |

|---|---|---|

| Best For | Large-scale, high-volume production | Small businesses, lower-volume runs |

| Operation | Hands-free: auto-feeds, fills, seals | Operator places containers, machine fills |

| Key Benefit | Maximum throughput and efficiency | High precision with lower initial investment |

Ready to Scale Your Production with Precision?

As a leading supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the critical need for reliable, high-speed equipment. An automatic filling machine can transform your honey packing operation, ensuring consistent fill levels, reducing waste, and dramatically increasing your output.

Let our experts help you select the perfect filling solution for your specific needs. Contact HONESTBEE today to discuss how our wholesale-focused equipment can boost your efficiency and profitability.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- Semi Automatic Round Bottle Labeling Machine

- HONESTBEE 24 Head Rotary Bottle Washing Machine

People Also Ask

- What types of products can volumetric filling machines handle? From Thin Liquids to Thick Pastes

- What causes jamming or blockage of film in honey stick machines? Prevent Costly Downtime

- What role do automatic honey-filling machines play? Enhancing Honey Purity and Commercial Sustainability

- How do automated filling production lines improve honey product development? Boost Your Economic Efficiency & ROI

- What is the significance of industrial honey-filling machines? Scale Your Commercial Apiary with Precision Automation

- What equipment is used for packaging honey? A Guide to Filling, Capping & Labeling Systems

- What precautions should be taken when packing honey? Ensure Quality from Hive to Jar

- What is the function of industrial-grade plastic funnels in honey bottling? Essential Tools for Precision & Hygiene