At its core, the operating principle of a honey extractor is centrifugal force. This mechanical device uses a rapidly spinning cage to fling honey out of the comb's wax cells, allowing beekeepers to harvest the honey while leaving the delicate honeycomb structure completely intact for the bees to reuse.

A beekeeper's challenge is to remove honey from the comb without destroying the valuable wax structure that bees spend immense energy building. The honey extractor solves this elegantly by using the physics of rotation to separate liquid honey from the solid comb.

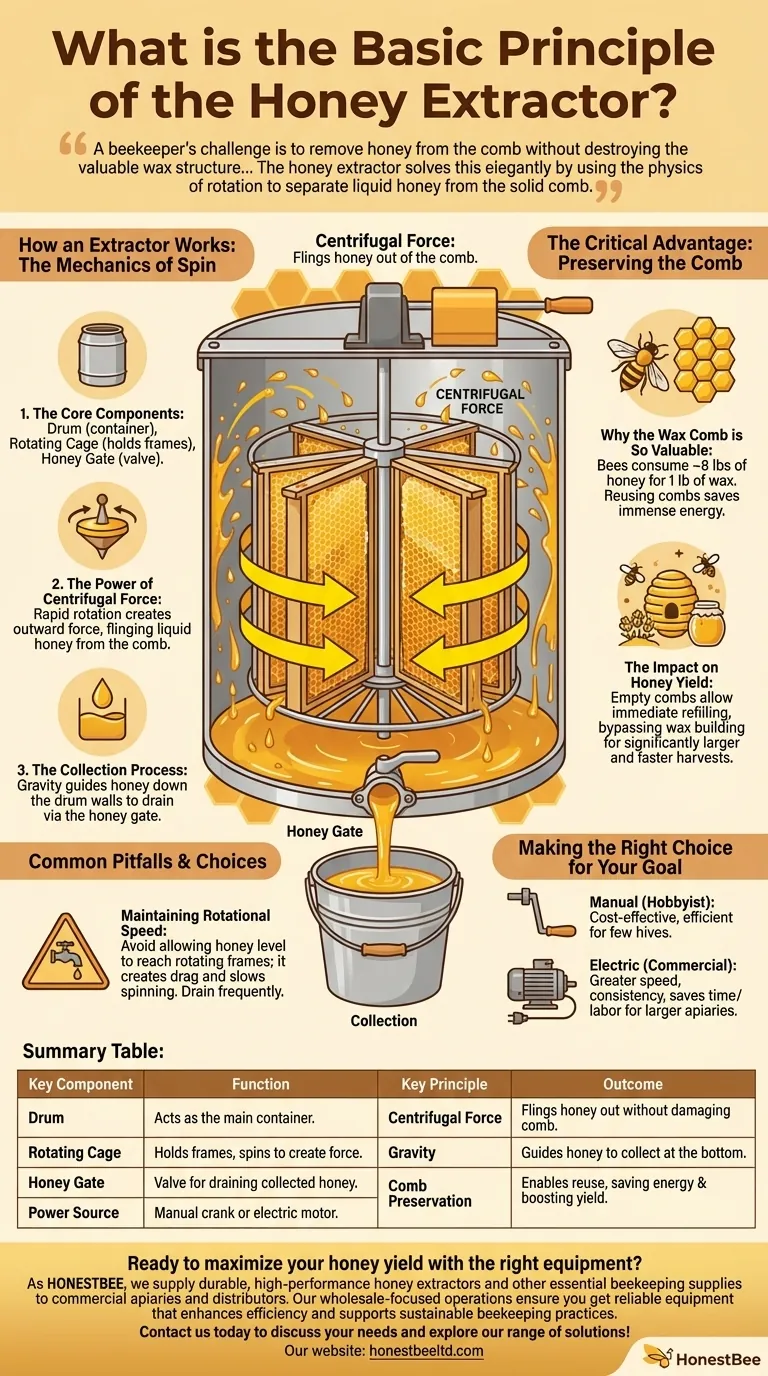

How an Extractor Works: The Mechanics of Spin

To understand the principle, it's helpful to break down the device into its key parts and processes. The design is simple but highly effective.

The Core Components

A honey extractor consists of three primary parts. The first is a large drum, typically made of stainless steel or food-grade plastic, which acts as the main container.

Inside this drum is a rotating basket or cage designed to hold the frames of honeycomb securely.

At the bottom of the drum is a valve or tap, often called a honey gate, which allows the collected honey to be drained out.

The Power of Centrifugal Force

The entire operation hinges on centrifugal force—the same outward force you feel on a fast-spinning merry-go-round.

When the beekeeper turns a crank or activates a motor, the inner cage holding the honey frames begins to spin at high speed.

This rapid rotation creates a strong outward force on the honey inside the uncapped wax cells. Because the honey is a liquid, it is flung from the comb and splatters against the inner wall of the drum.

The Collection Process

Once thrown against the drum wall, gravity takes over. The honey runs down the sides and pools at the bottom of the extractor.

The wax comb, being a solid structure held firmly in the cage, remains undamaged.

After the spinning is complete, the beekeeper can open the honey gate at the bottom to drain the pure, collected honey into buckets for filtering and bottling.

The Critical Advantage: Preserving the Comb

The true genius of the honey extractor is not just that it extracts honey, but that it does so without destruction. This is the key to efficient and sustainable beekeeping.

Why the Wax Comb is So Valuable

Bees must consume a significant amount of honey—roughly eight pounds—to produce just one pound of wax. Building an entire comb is an enormous energy investment for the colony.

By using an extractor, the beekeeper can return the empty, intact combs directly to the hive.

The Impact on Honey Yield

When bees are given empty combs, they can immediately begin refilling them with nectar, bypassing the slow, energy-intensive process of building new wax.

This allows the colony to dedicate its full energy to foraging and honey production, resulting in a much larger and faster honey harvest for the beekeeper.

Common Pitfalls to Avoid

While the principle is simple, proper operation is key to efficiency. A few practical considerations ensure the extractor works as intended.

Manual vs. Electric Power

The spinning action can be powered in two ways. Manual extractors use a hand crank, which is cost-effective and ideal for hobbyists with only a few hives.

Electric extractors use a motor, offering greater speed and consistency with less physical effort. They are the standard choice for beekeepers with larger operations.

Maintaining Rotational Speed

For the centrifugal force to be effective, the cage must spin at a sufficient speed. A common mistake is allowing the collected honey to rise too high inside the drum.

If the honey level reaches the rotating frames, it creates drag that slows the spin, making extraction inefficient or impossible. The honey must be drained periodically to keep the frames clear.

Making the Right Choice for Your Goal

Understanding this principle allows you to select the right equipment and process for your specific beekeeping needs.

- If your primary focus is small-scale hobby beekeeping: A manual extractor offers a perfect balance of cost and functionality, allowing you to harvest honey efficiently without a large investment.

- If your primary focus is maximizing efficiency for a larger apiary: An electric extractor is a necessary tool that will save you significant time and labor, directly increasing your operation's productivity.

By harnessing centrifugal force, the honey extractor transforms honey harvesting from a destructive process into a sustainable cycle that benefits both the beekeeper and the bees.

Summary Table:

| Key Component | Function |

|---|---|

| Drum | Acts as the main container to collect the extracted honey. |

| Rotating Cage | Holds honey frames securely and spins to create centrifugal force. |

| Honey Gate | A valve at the bottom for draining the collected honey. |

| Power Source | Manual crank or electric motor to spin the cage at high speed. |

| Key Principle | Outcome |

|---|---|

| Centrifugal Force | Flings liquid honey out of the wax cells without damaging the comb. |

| Gravity | Allows honey to run down the drum walls and pool at the bottom for collection. |

| Comb Preservation | Enables bees to reuse the wax, saving energy and boosting honey production. |

Ready to maximize your honey yield with the right equipment?

As HONESTBEE, we supply durable, high-performance honey extractors and other essential beekeeping supplies to commercial apiaries and distributors. Our wholesale-focused operations ensure you get reliable equipment that enhances efficiency and supports sustainable beekeeping practices.

Contact us today to discuss your needs and explore our range of solutions!

Visual Guide

Related Products

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Commercial 48-Frame Stainless Steel Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

People Also Ask

- What are the technical contributions of Centrifugal Honey Extractors? Maximize Harvest Efficiency & Reuse Your Combs

- What are the technical advantages of movable frames? Boost Beekeeping Yield Through Non-Destructive Harvesting

- How does increasing the frequency of honey extraction contribute to higher honey yields? Boost Your Apiary Productivity

- How does an advanced centrifugal honey extractor maintain honey quality? Ensure Purity with Non-Destructive Extraction

- How does a Centrifugal Honey Extractor contribute to the efficiency of the honey harvesting process? Maximize Your Yield