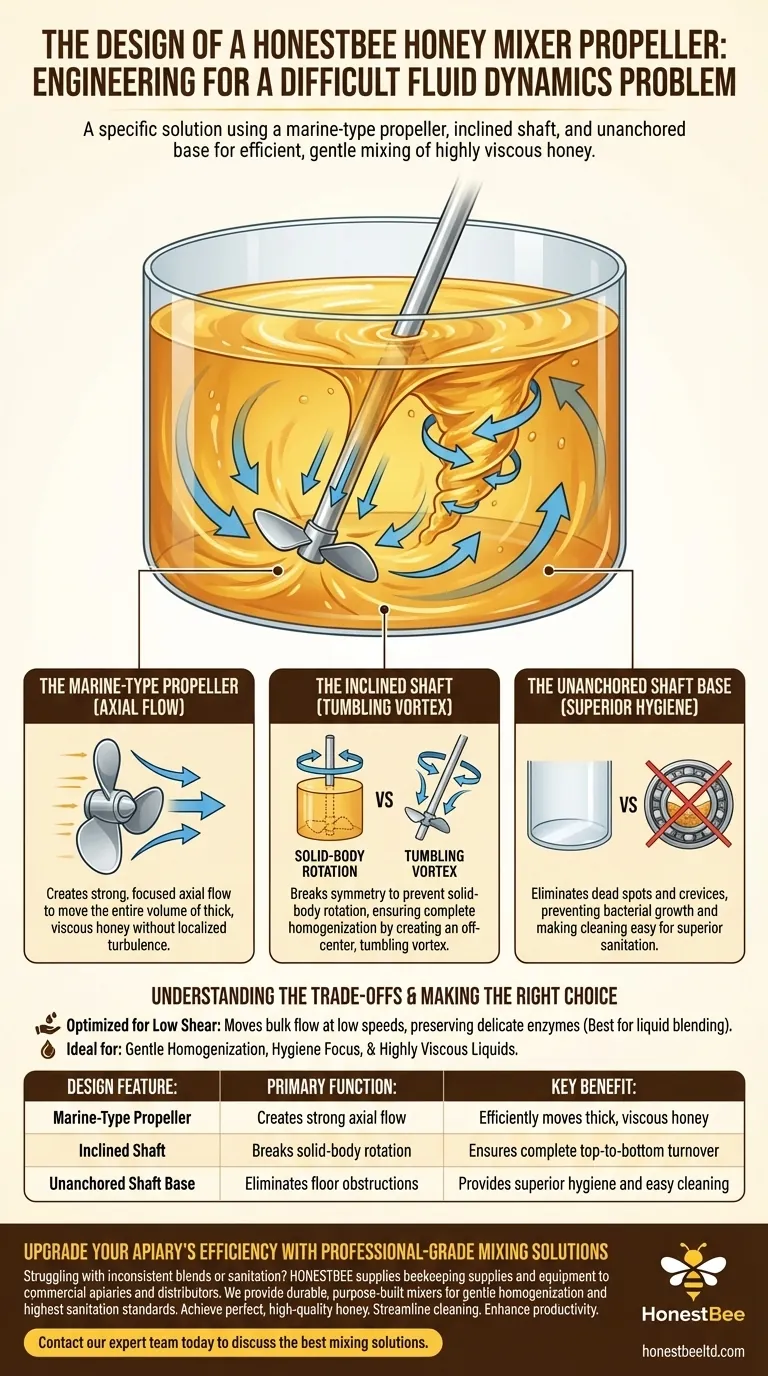

The design of a honey mixer's propeller is a specific engineering solution for a difficult fluid dynamics problem. It utilizes a marine-type propeller mounted on an inclined shaft that is not anchored to the tank bottom. This configuration is purpose-built to efficiently mix a highly viscous fluid like honey without degrading its quality.

The challenge with honey is not just mixing, but doing so gently and completely. The combination of a marine propeller, an inclined shaft, and an unanchored mount is a deliberate system designed to create a specific, non-symmetrical flow pattern that ensures homogenization without introducing air or creating sanitation problems.

Why This Specific Design Works

To understand the effectiveness of this setup, we must look at each component's role in overcoming the unique challenges of mixing honey. The design directly addresses viscosity, aeration, and sanitation.

The Marine-Type Propeller

The use of a marine-type propeller is intentional. Unlike simple paddles that create drag and localized turbulence, a marine propeller is designed for axial flow.

This means it efficiently pushes the fluid (honey) in a powerful, focused stream along the axis of the shaft. This creates a strong, large-scale current necessary to move the entire volume of a thick, viscous product.

The Inclined Shaft

Mounting the shaft at an incline is the most critical element for achieving a proper mix. A vertical, centrally mounted mixer in a round tank often fails with viscous fluids.

This is because a centered shaft can cause the entire mass of honey to spin as one solid block, a phenomenon called solid-body rotation. Very little actual mixing between layers occurs.

The inclined shaft breaks this symmetry. It creates an off-center, tumbling vortex that forces the top layers of honey to fold down and the bottom layers to be pulled up, ensuring a complete top-to-bottom turnover of the product.

The Unanchored Shaft Base

The detail that the shaft is not anchored to the tank bottom is a critical design choice for hygiene and product quality.

An anchor point or support bearing on the floor of the tank would create a "dead spot" and a crevice. This area would be extremely difficult to clean, trapping product, promoting crystallization, and becoming a potential site for bacterial growth.

By keeping the tank floor smooth and unobstructed, the design ensures superior sanitation and prevents product loss or contamination.

Understanding the Trade-offs

While highly effective, this design has specific operational boundaries. It is optimized for a particular task, and understanding its limitations is key.

Optimized for Low Shear

This system is designed to create bulk flow at relatively low speeds. The goal is to move the entire mass, not to create high-speed, high-shear zones. Excessive shear can damage the delicate enzymes and structure of honey.

Best for Liquid Blending

The marine propeller is excellent for liquid-liquid blending or dissolving existing crystals (liquefying). It is less effective for incorporating large solids or creating fine emulsions, which might require different impeller geometries like a high-shear disperser.

Making the Right Choice for Your Goal

This design is a masterclass in applying fluid dynamics to a specific food processing challenge.

- If your primary focus is gentle, complete homogenization: This design is ideal, as the tumbling vortex ensures all the product is mixed without introducing damaging shear or air.

- If your primary focus is hygiene and sanitation: The unanchored, top-entry design is superior, as it leaves the tank floor smooth and completely free of hard-to-clean obstructions.

- If your primary focus is mixing highly viscous liquids: The combination of a thrust-oriented marine propeller and an inclined shaft is purpose-built to overcome the solid-body rotation that plagues standard mixers.

Ultimately, this design represents a precise solution tailored to preserve the quality and integrity of a delicate and challenging product.

Summary Table:

| Design Feature | Primary Function | Key Benefit |

|---|---|---|

| Marine-Type Propeller | Creates strong axial flow | Efficiently moves thick, viscous honey |

| Inclined Shaft | Breaks solid-body rotation | Ensures complete top-to-bottom turnover |

| Unanchored Shaft Base | Eliminates floor obstructions | Provides superior hygiene and easy cleaning |

Upgrade Your Apiary's Efficiency with Professional-Grade Mixing Solutions

Struggling with inconsistent honey blends or sanitation concerns in your commercial operation? The right equipment is critical for product quality and operational hygiene.

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors. We provide the durable, purpose-built honey mixers your business needs to ensure gentle homogenization and meet the highest sanitation standards.

Let us help you:

- Achieve perfectly blended, high-quality honey every time.

- Streamline your cleaning process with equipment designed for hygiene.

- Enhance your productivity with reliable, commercial-grade machinery.

Contact our expert team today to discuss the best mixing solutions for your commercial apiary or distribution needs.

Visual Guide

Related Products

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Modern Stainless Steel Honey Dipper Stirrer

- 10L Stainless Steel Electric Honey Press Machine

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Heavy Duty 304 Stainless Steel Honey Dipper

People Also Ask

- How does industrial mixing equipment ensure the quality of whipped honey? Achieve Perfect Texture and Consistency

- How does a high-speed vortex mixer influence extraction efficiency? Maximize Honey Pretreatment Speed

- What is the role of processing and mixing equipment in honey beverages? Master Professional Blending & Quality Control

- What are the equipment requirements for honeybee feed additives? Master High-Viscosity Mixing with Lactulose and Inulin

- What are the processing advantages of producing Cream Honey? Turn High-Glucose Varieties into Smooth Premium Products

- Why is an electric mixer necessary for pollen substitutes? Achieve Molecular Gelatinization for Superior Bee Health

- Why is professional processing mixing equipment necessary? Create Premium Honey-Infused Products with Precision

- Why is large-capacity homogenization mixing equipment used in the preparation of bee pollen? Achieve High-Quality Feed