At its core, the forming tube is the component responsible for shaping the flat packaging film into the final, cylindrical stick pack. This conical device, located in the machine's central section, expertly folds the film around it, creating the foundational tube structure before it is sealed and filled with honey.

The forming tube is not just a part; it is the starting point for the package itself. Its primary function is to transform a two-dimensional film into a three-dimensional container, setting the stage for every subsequent action in the production process.

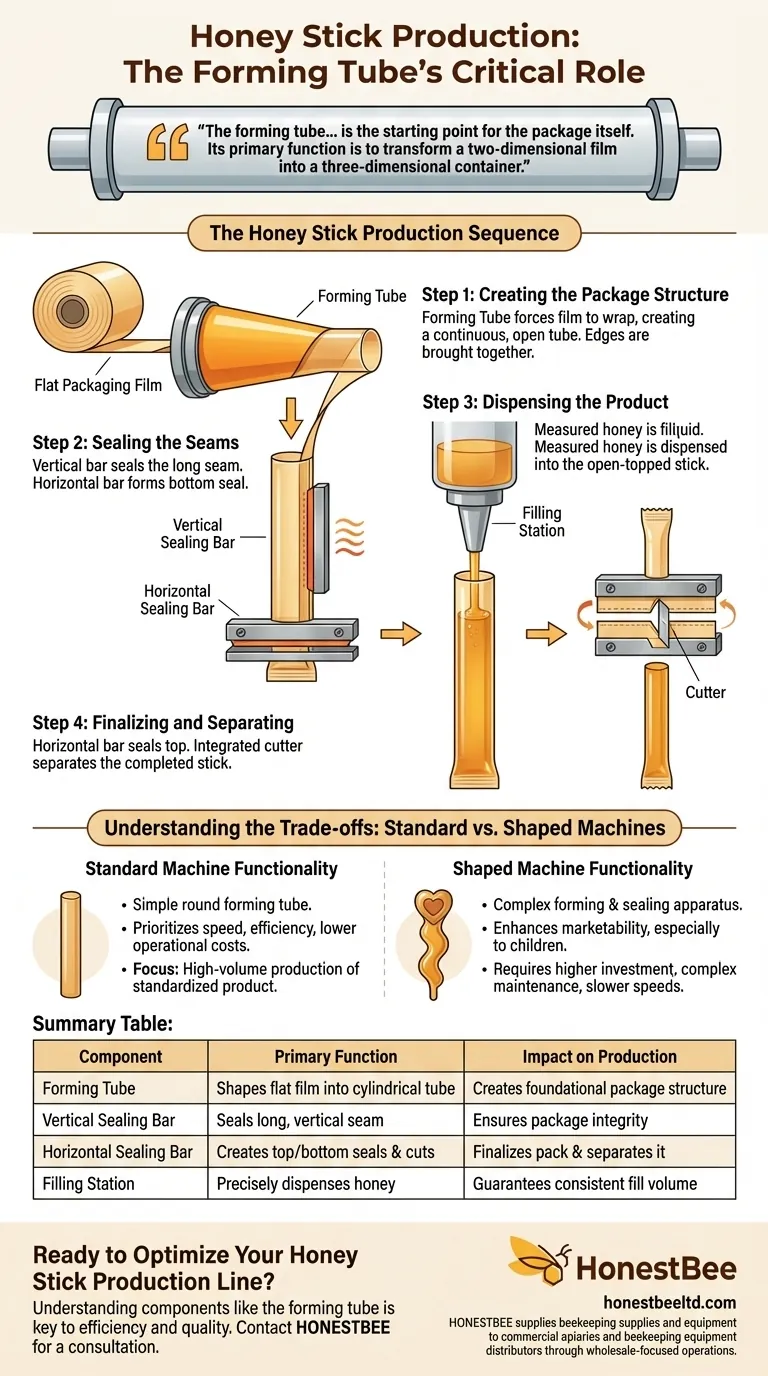

The Honey Stick Production Sequence

To truly understand the forming tube's role, it's essential to see it as the first step in a precise, sequential operation. Each component of the machine performs a specific task that builds upon the last.

Step 1: Creating the Package Structure

The process begins with a roll of flat packaging film being fed into the machine. This film is pulled over the forming tube, which forces the flat material to wrap around it, creating a continuous, open-ended tube.

The two outer edges of the film are brought together at this stage, preparing them to be permanently joined.

Step 2: Sealing the Seams

Once the film is shaped, the vertical sealing bar applies high temperature and pressure. This action melts and fuses the two edges of the film together, creating the long, vertical seam of the honey stick.

Next, the horizontal sealing bar clamps down on the tube. It creates the bottom seal for one stick and the top seal for the stick that was just filled, all in a single motion.

Step 3: Dispensing the Product

With the bottom seal in place, the filling station precisely dispenses a measured amount of honey into the open-topped stick. This station uses pumps and pistons to ensure accuracy and consistency for every single stick.

Step 4: Finalizing and Separating

The horizontal sealing bar then activates again to create the top seal of the now-filled stick. Embedded within this bar is a sharp blade, the cutter, which simultaneously slices the completed honey stick, separating it from the rest of the film.

Understanding the Trade-offs: Standard vs. Shaped Machines

While the core mechanics are similar, the forming and sealing process can vary based on the type of machine. This choice has direct implications for production cost and market appeal.

Standard Machine Functionality

A standard machine uses a simple, round forming tube to create the classic, uniform honey stick. This approach prioritizes speed, efficiency, and lower operational costs.

The focus is purely on high-volume production of a standardized product.

Shaped Machine Functionality

A shaped honey stick machine uses a more complex forming and sealing apparatus to create unique shapes and styled seals. This can significantly enhance the product's marketability, especially to audiences like children.

However, this specialization requires a higher initial investment and may involve more complex maintenance and slower production speeds compared to standard machines.

How to Apply This to Your Goal

Your understanding of this process should inform your equipment and production strategy.

- If your primary focus is high-volume, cost-effective production: A standard machine with a simple forming tube is the most direct path to efficient output.

- If your primary focus is brand differentiation and premium marketing: Investing in a shaped honey stick machine allows you to create a unique product that stands out on the shelf.

Ultimately, recognizing the function of each component allows you to make an informed decision that aligns your production capabilities with your business objectives.

Summary Table:

| Component | Primary Function | Impact on Production |

|---|---|---|

| Forming Tube | Shapes flat film into a cylindrical tube | Creates the foundational package structure |

| Vertical Sealing Bar | Seals the long, vertical seam of the stick | Ensures package integrity and leak prevention |

| Horizontal Sealing Bar | Creates top/bottom seals and cuts the finished stick | Finalizes the pack and separates it from the film |

| Filling Station | Precisely dispenses honey into the open tube | Guarantees consistent fill volume and product weight |

Ready to Optimize Your Honey Stick Production Line?

Understanding the critical role of each component, like the forming tube, is the first step toward maximizing your efficiency and product quality. Whether your goal is high-volume output with a standard machine or unique brand differentiation with a shaped machine, the right equipment is key.

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. We provide the reliable machinery and expert support you need to scale your honey packaging operation successfully.

Contact HONESTBEE today for a consultation and let us help you select the perfect honey stick machine to meet your specific production goals and budget.

Visual Guide

Related Products

- Manual Honey Filling Machine Bottling Machine for Honey

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What is the purpose of a Honey Tube Filling Machine? Boost Portability and Precision in Your Production

- What is the recommended temperature for honey during the straw-filling process? Optimize Your Honey Flow & Quality

- What are the main types of volumetric filling machines? Find the Right Filler for Your Product

- What are the types of honey filling machines? Choose the Right Filler for Your Production Scale

- What are the key features to look for in a honey filling machine? Precision & Versatility for Your Apiary

- How can a honey filler be adapted for different types of containers? Master Multi-Container Filling Efficiency

- How do professional filling machines contribute to the final production stage of honey products? Boost Your Efficiency

- How do industrial honey-filling and processing machines contribute to regional food security? Stabilizing Supply Chains