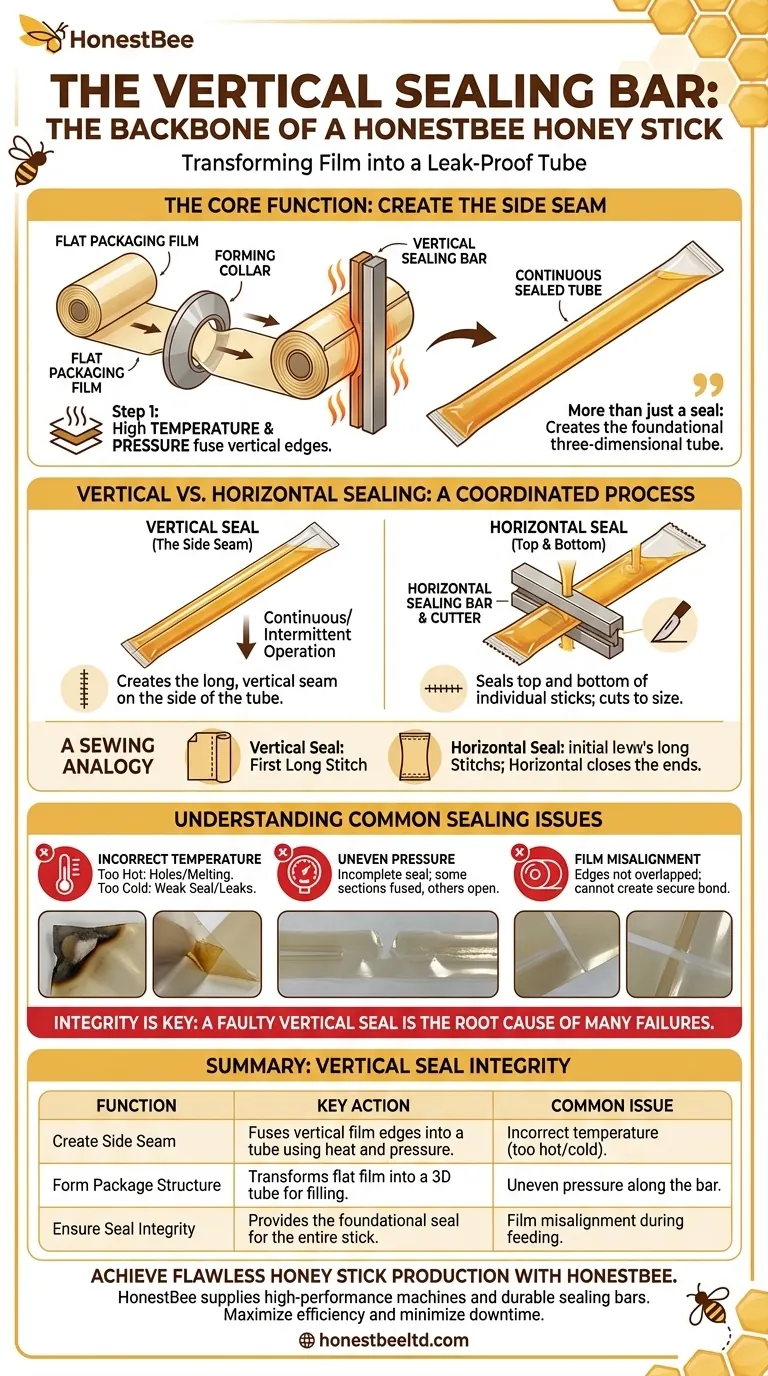

At its core, the vertical sealing bar in a honey stick machine performs the critical first step in forming the package. It uses a combination of high temperature and pressure to fuse the two vertical edges of a flat packaging film together, creating a continuous, sealed tube.

The vertical sealer's function is not just to seal, but to transform a two-dimensional film into a three-dimensional tube. This tube is the foundational structure that is then filled with honey and cut into individual sticks by the horizontal sealer.

How the Vertical Seal Creates the Honey Stick Tube

Understanding the vertical sealing bar requires seeing it as the starting point of the packaging process. Its sole job is to create the long, continuous seam that runs the length of every honey stick.

The Principle of Heat and Pressure

The sealing bar is a heated metal component. It clamps down on the overlapping edges of the packaging film.

This combination of high temperature and mechanical pressure melts the inner, heat-sensitive layers of the film, causing them to fuse together into a permanent, leak-proof bond.

From Flat Film to Sealed Tube

Imagine a roll of flat plastic film being fed into the machine. As it passes the forming collar, it is shaped into a cylinder.

The vertical sealing bar is positioned precisely at the point where the two long edges of this newly-formed cylinder meet. By sealing these edges, it creates an endless, hollow tube.

Vertical vs. Horizontal Sealing: A Coordinated Process

The honey stick machine uses two distinct sealing systems that must work in perfect harmony. Confusing their roles is a common point of misunderstanding.

The Vertical Seal's Job: The Side Seam

The vertical bar's responsibility is singular: to create the long, vertical seam on the side of the tube. It operates continuously or intermittently as the film is pulled through the machine.

The Horizontal Seal's Job: The Top and Bottom

The horizontal sealing bar works perpendicularly to the vertical seal. After a set amount of honey is dispensed into the tube, the horizontal bar clamps down.

This single action accomplishes two things: it seals the top of the stick below it and the bottom of the stick above it, while a blade simultaneously cuts the finished stick free.

A Sewing Analogy

Think of making a simple cloth bag. The vertical seal is like the first long stitch that turns a flat piece of fabric into a tube. The horizontal seal is like the subsequent stitches that close off the bottom and, after filling, the top.

Understanding Common Sealing Issues

A faulty vertical seal is the root cause of many production line failures. The integrity of the entire package depends on this initial step.

Incorrect Temperature

If the bar is too hot, it can burn or melt through the film, causing holes. If it is too cold, the film layers will not fuse properly, resulting in a weak seal that can easily peel open or leak.

Uneven Pressure

If the sealing bar does not apply consistent pressure along its entire length, you will get an incomplete seal. Some sections will be fused while others remain open, creating a guaranteed point of failure.

Film Misalignment

Proper alignment of the film edges as they enter the vertical sealer is critical. If the edges are not perfectly overlapped, the bar will not be able to create a secure bond, leading to immediate leaks.

Making the Right Choice for Your Goal

Understanding this component's function is key to managing production quality and troubleshooting effectively.

- If your primary focus is quality control: Regularly inspect the vertical seam for consistency and test its strength to ensure proper temperature and pressure settings.

- If your primary focus is troubleshooting leaks: The vertical seam is the first place to investigate, as a failure here affects every single stick produced.

- If your primary focus is machine setup: Ensure the film is tracking perfectly and that the vertical sealing jaws are clean and aligned before starting a production run.

Ultimately, the vertical seal is the backbone of the honey stick; without its integrity, the entire package fails.

Summary Table:

| Function | Key Action | Common Issue |

|---|---|---|

| Create Side Seam | Fuses vertical film edges into a tube using heat and pressure. | Incorrect temperature (too hot/cold). |

| Form Package Structure | Transforms flat film into a 3D tube for filling. | Uneven pressure along the bar. |

| Ensure Seal Integrity | Provides the foundational seal for the entire stick. | Film misalignment during feeding. |

Achieve flawless, leak-proof honey stick production. A properly functioning vertical sealing bar is critical for your output quality. HONESTBEE supplies high-performance honey stick machines and replacement parts, including durable sealing bars, to commercial apiaries and beekeeping equipment distributors. Let our expertise help you maximize your packaging line's efficiency and minimize downtime.

Contact HONESTBEE today to discuss your specific needs and get a quote for reliable beekeeping equipment.

Visual Guide

Related Products

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- How does the horizontal sealing bar operate in a honey stick machine? Master the Final Sealing Step

- How do high-precision honey filling machines handle stingless honey? Scale Your Commercial Packaging with Precision

- What are the benefits of high-precision automatic filling machinery? Scale Your Honey Business Profitably

- What are the core advantages of using industrial honey-filling machines? Ensure Purity & Hygiene at Scale

- What is the primary advantage of an overflow filling machine? Ensure Perfect Shelf Appeal with Uniform Fill Levels

- How does a piston filling machine work and why is it suitable for honey? Master High-Viscosity Packaging

- How do food-grade honey storage tanks and filling equipment contribute to the commercialization of bee products?

- How do industrial automatic honey-filling machines contribute to product quality? Ensure Precision and Purity