Ultimately, the right tools are not an expense but an investment. They are foundational to transforming a beekeeping operation from a simple hobby into a productive, efficient, and reputable enterprise. Using the correct equipment directly impacts honey quality, operational efficiency, and the overall safety and marketability of the final product.

The core principle is simple: quality tools produce quality honey. Investing in the right equipment is the most direct path to ensuring purity, maximizing yield, and reducing the manual labor inherent in beekeeping, which builds a more sustainable and profitable operation.

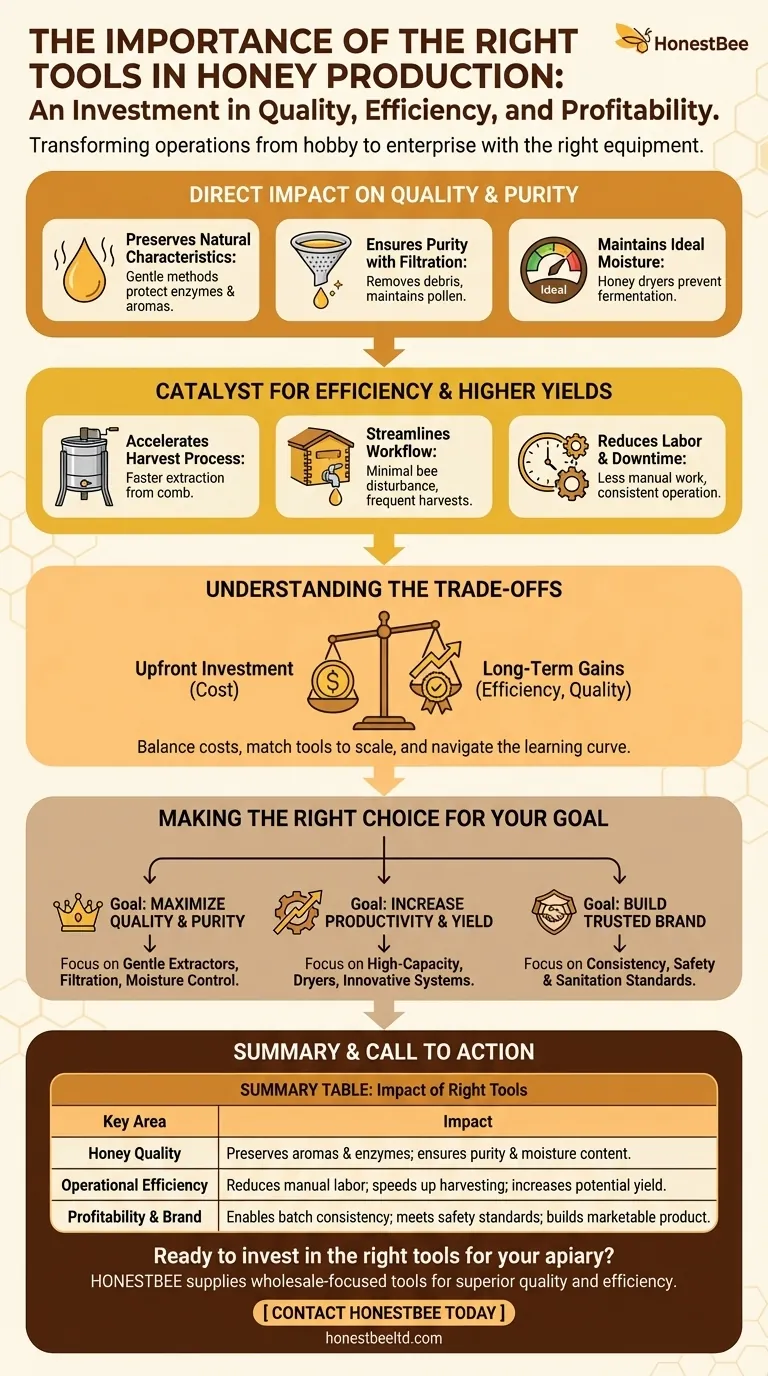

The Direct Impact on Honey Quality and Purity

The equipment you use has a direct and measurable effect on the honey you produce. It is the primary factor that determines whether you are preserving the natural, delicate qualities of the honey or inadvertently degrading them during processing.

Preserving Natural Characteristics

High-quality, modern equipment is designed to be gentle. Gentle extraction and processing methods ensure that the honey's sensitive substances, natural aromas, and beneficial enzymes are not damaged by excessive heat or agitation.

Ensuring Purity with Filtration

Proper filtration systems are crucial for removing impurities like wax bits, bee parts, and other hive debris. Effective filters clean the honey while preserving its natural pollen content and other desirable qualities, resulting in a pure, clear, and safe product.

Maintaining Ideal Moisture Content

A honey dryer is a specialized tool that allows beekeepers to harvest honey before it is fully capped by the bees. This technology gently removes excess moisture without damaging the honey, which significantly increases the potential harvest per season and ensures the final product has the correct water content to prevent fermentation.

A Catalyst for Efficiency and Higher Yields

Beyond quality, the right tools are the engine of productivity. They reduce manual labor, speed up processes, and ultimately allow for a greater honey yield with less effort.

Accelerating the Harvest Process

Modern equipment, such as centrifugal extractors, dramatically shortens the time it takes to get honey from the comb into the container. Innovative systems like the Flow Hive further streamline this process, enabling honey extraction with minimal disturbance to the bees, which can lead to more frequent harvests.

Reducing Manual Labor and Downtime

Reliable, well-designed equipment requires less manual intervention and oversight. It also minimizes maintenance-related downtime, ensuring your operation can run consistently and predictably during the critical harvest season. This shift from labor-intensive work to efficient processing allows beekeepers to manage more hives effectively.

Understanding the Trade-offs

While the benefits are clear, selecting the right equipment involves balancing costs, scale, and long-term goals. An objective assessment is necessary to make the right choice for your specific operation.

The Upfront Investment

Quality processing equipment represents a significant financial investment. The initial cost can be a barrier, but it must be weighed against the long-term gains in efficiency, product quality, and reduced labor costs.

Matching Tools to Operational Scale

The needs of a small-scale hobbyist are vastly different from those of a commercial producer. Over-investing in industrial-grade equipment for a few hives is inefficient, while trying to run a large operation with hobbyist tools will create bottlenecks and compromise quality.

The Learning Curve

New technologies, particularly innovative systems like the Flow Hive or advanced extractors, come with a learning curve. Beekeepers must invest time in understanding how to use and maintain this equipment properly to realize its full potential.

Making the Right Choice for Your Goal

Your choice of tools should be driven by your primary objective as a beekeeper. By aligning your equipment with your goals, you can build a more effective and rewarding operation.

- If your primary focus is maximizing honey quality and purity: Invest in gentle extractors, effective filtration systems, and tools for moisture control to preserve the honey's natural integrity.

- If your primary focus is increasing productivity and yield: Prioritize high-capacity extractors, a honey dryer, and potentially innovative hive systems that accelerate the harvesting process.

- If your primary focus is building a trusted, marketable brand: Focus on equipment that guarantees batch-to-batch consistency and meets the highest safety and sanitation standards.

Proper tooling elevates beekeeping by ensuring the final product is a true reflection of the hard work done by both the beekeeper and the bees.

Summary Table:

| Key Area | Impact of the Right Tools |

|---|---|

| Honey Quality | Preserves natural aromas & enzymes; ensures purity and correct moisture content. |

| Operational Efficiency | Reduces manual labor; speeds up harvesting; increases potential yield. |

| Profitability & Brand | Enables batch consistency; meets high safety standards; builds a marketable product. |

Ready to invest in the right tools for your apiary?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused tools needed to achieve superior honey quality, maximize operational efficiency, and build a stronger brand. From gentle extractors and filtration systems to honey dryers, our equipment is an investment in your success.

Contact HONESTBEE today to discuss how our solutions can transform your honey production.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

People Also Ask

- What are the advantages of using industrial-grade stainless steel honey extractors vs. traditional methods?

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries

- What are the key features of the stainless steel honey press? Maximize Yield & Guarantee Purity

- How does pressed honey compare to extracted or crush-and-strain? Unlock the Full Flavor of the Hive

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping