The primary advantage is clear: an automatic viscous liquid filling machine fully automates the production process, delivering significantly faster and more precise filling than semi-automatic or manual methods. This capability is engineered to remove human-led process steps, which are the most common source of bottlenecks and inconsistency in a production line.

The choice between an automatic and semi-automatic machine is not merely about speed; it's a strategic decision about operational scale. The true advantage of an automatic machine is its ability to provide consistent, high-volume output with minimal human intervention, making it the superior choice for established, large-scale production.

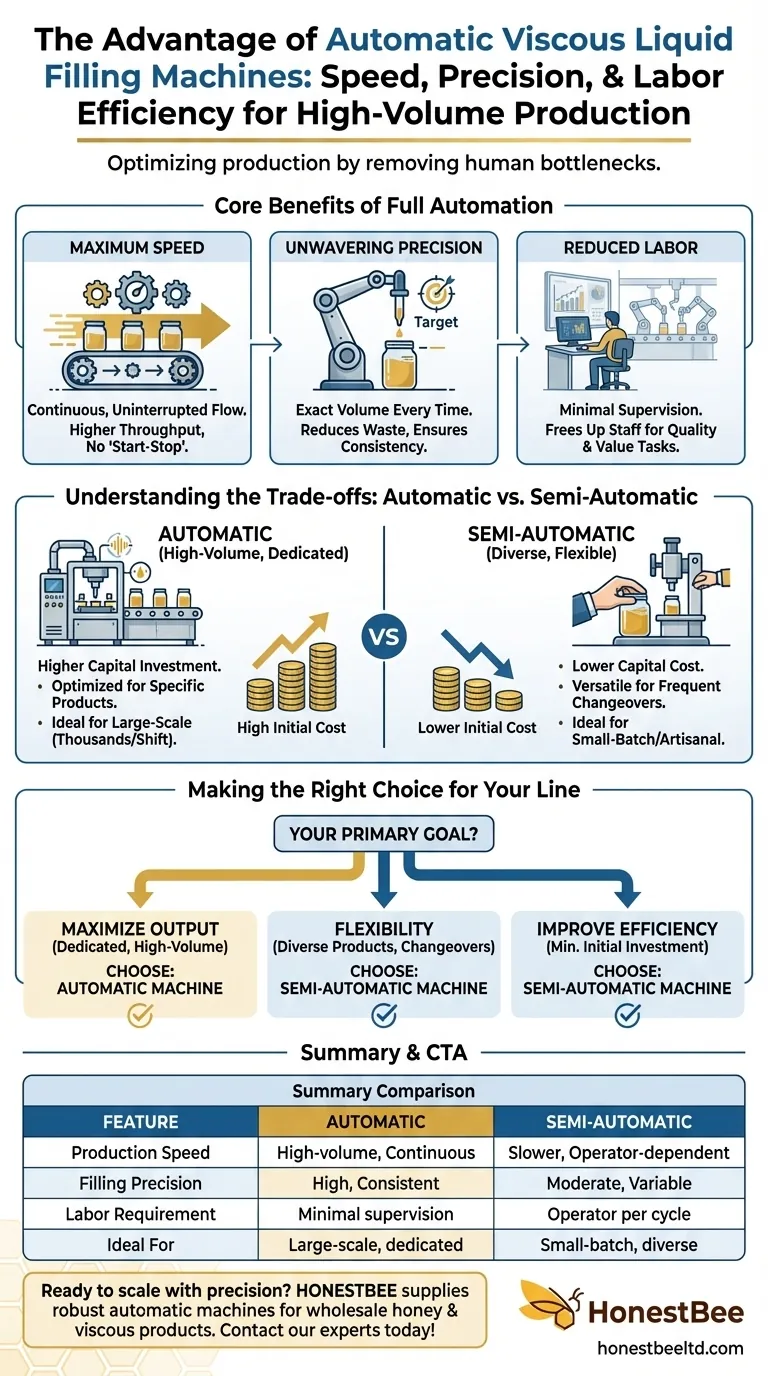

The Core Benefits of Full Automation

The decision to invest in a fully automatic system revolves around three key performance indicators: speed, precision, and labor efficiency. These are not minor improvements but transformative changes to a production line's capacity.

Unlocking Maximum Production Speed

An automatic machine operates in a continuous, uninterrupted flow. It handles every step from container positioning and filling to capping and labeling without needing an operator to initiate each cycle.

This removes the "start-stop" nature of semi-automatic processes, creating a predictable and dramatically higher throughput. The machine, not the operator, sets the pace of production.

Achieving Unwavering Filling Precision

Automated systems use advanced controls, such as servo-driven pumps or piston fillers, to dispense the exact same volume of liquid every single time. This level of accuracy is nearly impossible to replicate with manual oversight.

This precision directly reduces product waste, prevents costly overfills, and ensures your end customer receives a consistent product. For regulated industries, this documented consistency is a critical component of quality control.

Drastically Reducing Labor Requirements

A semi-automatic machine still requires an operator to place containers, activate the fill cycle, and remove the filled product. In contrast, a fully automatic line requires only supervision.

This frees up your skilled personnel from repetitive, low-value tasks, allowing them to focus on quality assurance, machine maintenance, and other activities that drive business value.

Understanding the Trade-offs: Automatic vs. Semi-Automatic

While an automatic machine offers superior performance for high-volume tasks, it is not the correct solution for every scenario. Understanding its trade-offs against a semi-automatic system is critical for making a sound investment.

The Cost of Investment

The primary barrier to an automatic machine is its significantly higher upfront capital cost. The complex conveyors, sensors, and integrated control systems represent a major investment.

Semi-automatic machines, as noted in their design, are far more cost-effective to purchase. They offer a powerful step up from manual filling without the financial commitment of a fully automated line.

Versatility and Changeover

Semi-automatic machines are often more versatile. They can be quickly adjusted to handle different container sizes, shapes, or product types with minimal downtime.

An automatic line is typically optimized for a specific container and product. While changeovers are possible, they are often more complex and time-consuming, making them less ideal for businesses with a high-variety, low-volume product mix.

The Scale of Operation

The decision ultimately comes down to your production volume. An automatic machine’s value is realized when running thousands of the same unit per shift.

For smaller businesses, startups, or those producing a wide range of artisanal products like spreads or honey, a semi-automatic machine provides the ideal balance of increased efficiency and operational flexibility.

Making the Right Choice for Your Production Line

Selecting the right machine requires an objective assessment of your operational goals, product portfolio, and financial reality. Use these points as your guide.

- If your primary focus is maximizing output for a dedicated, high-volume product: An automatic machine is the only choice to achieve the lowest cost-per-unit and meet large-scale demand.

- If your primary focus is flexibility for a diverse product line: A semi-automatic machine offers a more adaptable and cost-effective solution for managing frequent changeovers.

- If your primary focus is improving efficiency while minimizing initial investment: A semi-automatic machine provides a clear path to reducing labor costs and increasing consistency without the capital outlay of full automation.

Ultimately, the right machine aligns your production technology with your core business strategy.

Summary Table:

| Feature | Automatic Machine | Semi-Automatic Machine |

|---|---|---|

| Production Speed | High-volume, continuous flow | Slower, operator-dependent cycle |

| Filling Precision | High, consistent volume | Moderate, variable with operator |

| Labor Requirement | Minimal supervision needed | Requires operator per cycle |

| Ideal For | Large-scale, dedicated production | Small-batch, diverse product lines |

Ready to scale your production with precision?

For commercial apiaries and beekeeping equipment distributors, consistent, high-volume filling is key to profitability. HONESTBEE supplies robust automatic viscous liquid filling machines designed for the demands of wholesale operations. Our equipment ensures your honey, syrups, and other viscous products are filled quickly and accurately, batch after batch.

Contact our experts today to find the perfect filling solution for your business and maximize your output.

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

- Fully Automatic Honey Filling Packaging Machine for Processing Line

People Also Ask

- What is the working process of a sachet filling and packing machine? Optimize Your Packaging Line Efficiency

- How does viscosity affect the honey filling process? Optimize Your Honey Filling Line for Peak Efficiency

- What are the characteristics of a semi-automatic honey stick machine? Boost Your Packaging Efficiency

- What types of products can be filled and packed using sachet filling and packing machines? Versatile Packaging for Liquids, Pastes & Spreads

- What does the process of honey packaging typically involve? Expert Guide to Filling, Sealing & Preservation

- What is the process of filling and sealing honey stick packs? Master Efficient Packaging for Commercial Honey Sales

- How does automated honey filling machinery assist in controlling microbial contamination? Optimize Your Honey Purity

- What are the options for packing honey in a processing plant? Match Your Machine to Your Production Scale