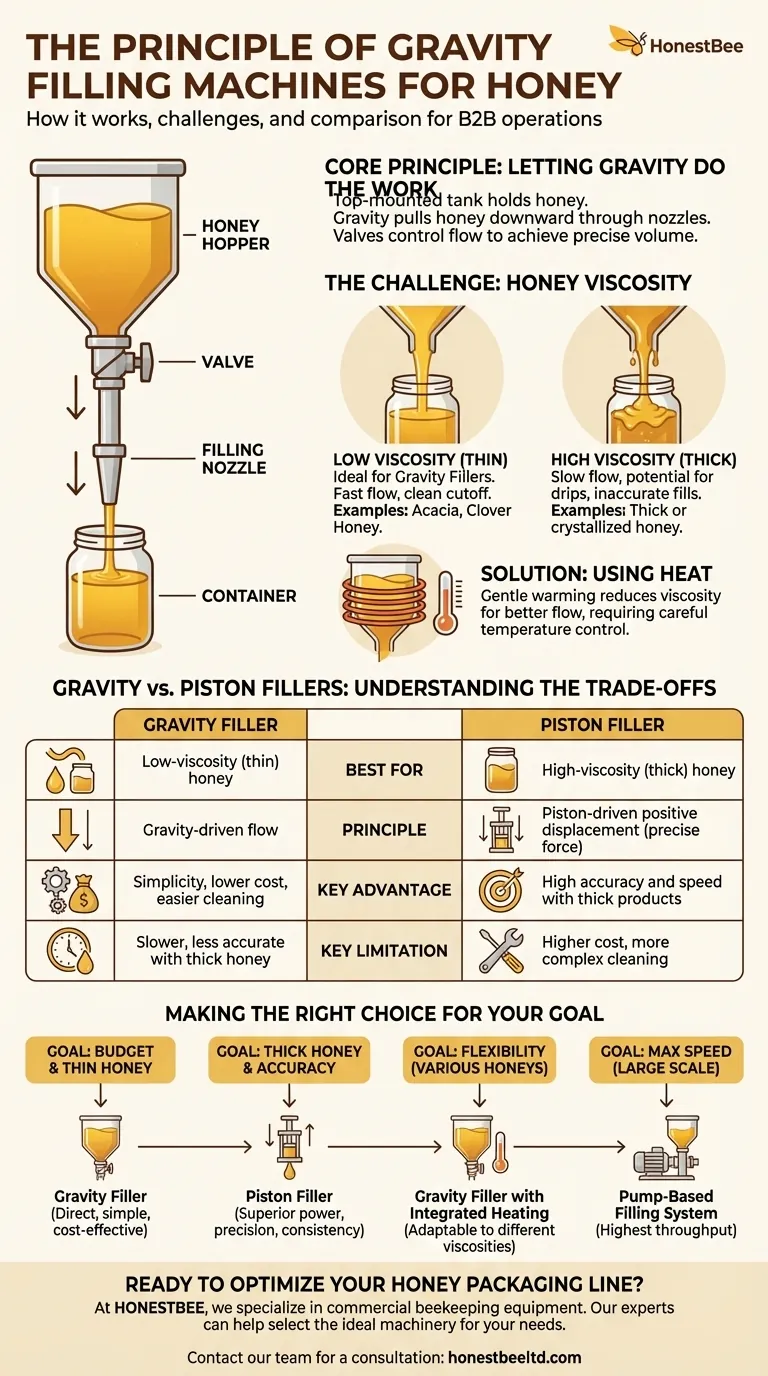

At its core, a gravity filling machine for honey operates on the simple principle of letting gravity do the work. The machine uses a top-mounted tank or hopper to hold the honey, which then flows downward through nozzles into containers positioned below. The flow is controlled by valves that open to fill and close once the desired volume is reached.

The central challenge in filling honey is its high viscosity. While gravity fillers offer simplicity and cost-effectiveness, their performance is directly tied to the honey's thickness, making them best suited for lower-viscosity liquid honey or operations that can modify viscosity through heating.

How a Gravity Filler Works

The Basic Mechanism

A gravity filler is designed around a straightforward vertical process. Honey is loaded into a large hopper, which serves as a reservoir at the highest point of the machine.

When the filling cycle begins, a valve connected to the hopper opens. Gravity pulls the honey from the hopper down through a filling nozzle and into the waiting jar or container.

Controlling the Fill Volume

Precision is achieved through the control of these valves. The machine stops the flow once the container has reached its target weight or volume. This can be timed or, in more advanced systems, managed by a scale that signals the valve to close at the precise moment.

The Critical Factor: Honey Viscosity

Why Viscosity Matters

Honey's natural thickness, or viscosity, is the single most important variable when considering a gravity filler. Thick, viscous honey flows very slowly under the force of gravity alone.

This slow flow can lead to inefficiently long fill times, reducing overall production speed. It can also make it difficult to achieve a clean, sharp cutoff when the valve closes, potentially leading to drips and inaccurate fills.

The Low-Viscosity Ideal

Gravity fillers perform best with low-viscosity (thinner) liquids. Therefore, they are an excellent match for naturally liquid honeys, like acacia or clover, that flow more easily.

Using Heat to Adapt

For thicker honeys, some filling lines incorporate a heating mechanism. By gently warming the honey in the hopper, its viscosity is reduced, allowing it to flow more freely. This makes gravity filling a viable option for a wider range of honey types, but requires careful temperature control to avoid damaging the honey's quality.

Understanding the Trade-offs: Gravity vs. Piston Fillers

The most common alternative to a gravity filler is a piston filler. Understanding the difference is key to making an informed decision.

Gravity Fillers: Simplicity and Cost

- Best For: Thin, low-viscosity honey.

- Advantage: Mechanically simple, easier to clean, and generally lower in cost.

- Limitation: Struggles with thick, high-viscosity honey, which can result in slow fills and potential inaccuracies.

Piston Fillers: Power and Precision

- Best For: Thick, viscous honey.

- Advantage: A piston actively pushes a precise volume of honey out of a cylinder. This provides the force needed to handle thick products quickly and with high accuracy, regardless of viscosity changes.

- Limitation: More mechanically complex, which can translate to a higher initial cost and more intensive cleaning procedures.

Pump Fillers: High-Speed Operations

For very large-scale, high-speed production, pump-based systems are also used. These systems use a pump to continuously regulate the flow of honey to the filling nozzles, prioritizing throughput above all else.

Making the Right Choice for Your Goal

To select the correct machine, you must first define your primary operational need.

- If your primary focus is handling low-viscosity honey on a budget: A gravity filler is the most direct, simple, and cost-effective solution.

- If your primary focus is accurately packaging thick, viscous honey: A piston filler is the superior choice for its power, precision, and consistency.

- If your primary focus is adapting to various honey types: A gravity filler with an integrated heating system offers valuable flexibility.

- If your primary focus is maximizing speed for large-scale production: A pump-based filling system is designed for the highest throughput.

Ultimately, choosing the right filling technology depends on a clear understanding of your specific product and production goals.

Summary Table:

| Aspect | Gravity Filler | Piston Filler |

|---|---|---|

| Best For | Low-viscosity (thin) honey | High-viscosity (thick) honey |

| Principle | Gravity-driven flow | Piston-driven positive displacement |

| Key Advantage | Simplicity, lower cost, easier cleaning | High accuracy and speed with thick products |

| Key Limitation | Slower, less accurate with thick honey | Higher cost, more complex cleaning |

Ready to optimize your honey packaging line?

At HONESTBEE, we specialize in supplying the right beekeeping equipment for commercial apiaries and distributors. Whether a gravity filler is perfect for your liquid honey or you need the power of a piston filler for thicker products, our experts can help you select the ideal machinery to boost your efficiency and accuracy.

Contact our team today for a personalized consultation and discover how our wholesale-focused solutions can benefit your operation!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do automated honey-filling machines and processing equipment help apiaries mitigate risks? Beat Climate-Induced Yields

- Why are professional-grade honey filling machines necessary? Boost Accuracy and Hygiene in Commercial Production

- How does the physicochemical analysis of honey inform filling processes? Optimize Your Commercial Production Line

- Why are industrial high-precision honey filling machines essential? Scale Your Production with Accuracy & Hygiene

- Why is it necessary to ensure honey reaches a water content range of 14-17%? Optimize Your Filling and Shelf Stability

- What are the maintenance requirements for honey packaging machines? Prevent Downtime with a Simple Cleaning Routine

- Why is customer support important when purchasing a honey filling machine? Ensure Maximum Uptime for Your Bottling Line

- What is the role of automated honey filling machines in the green supply chain? Ensure Purity & Precision