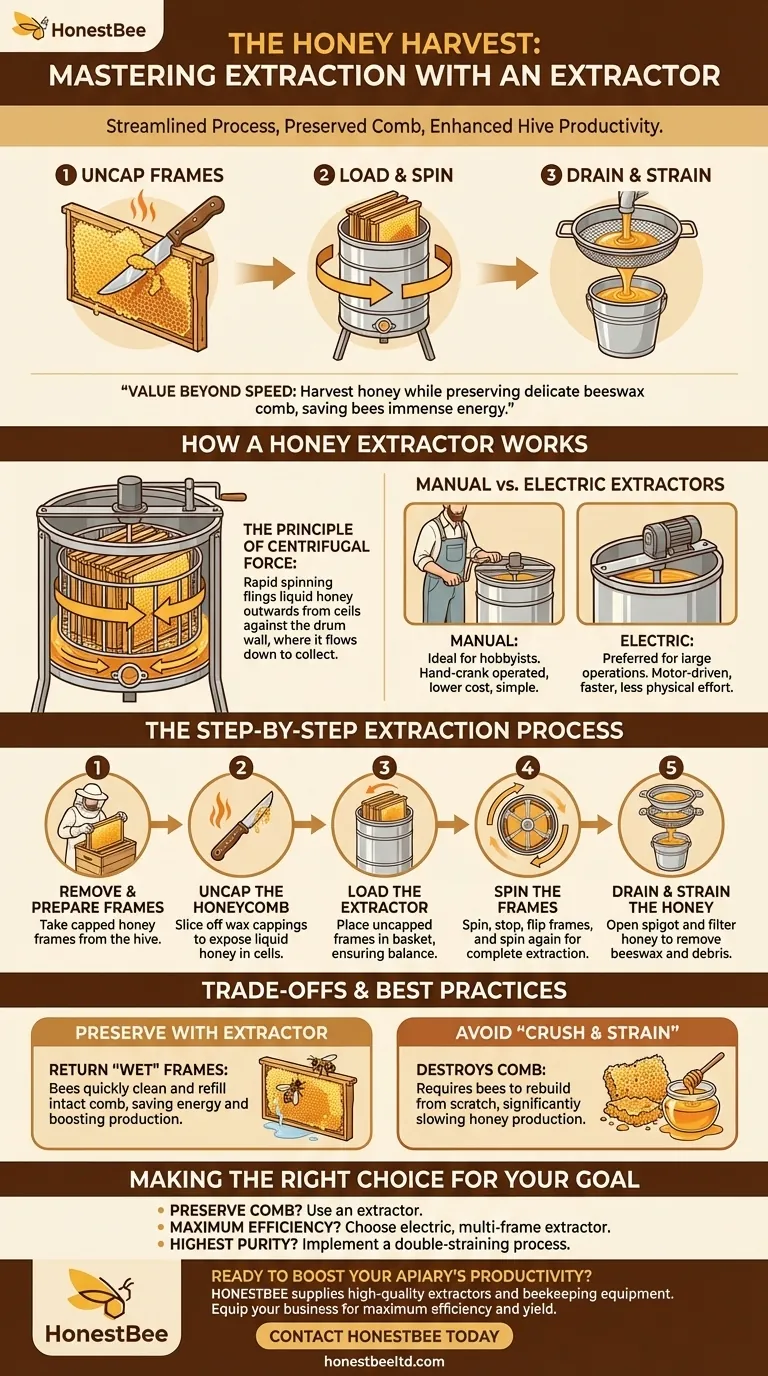

At its core, using a honey extractor is a straightforward, multi-step process. You must first uncap the honeycomb frames to expose the honey, place them inside the extractor's baskets, and then spin the machine to use centrifugal force to pull the honey out of the comb. The collected honey is then drained and strained for storage.

The true value of a honey extractor is not just its speed, but its ability to harvest honey while preserving the delicate beeswax comb. This allows the bees to refill the comb immediately, saving them immense energy and boosting the hive's overall productivity.

How a Honey Extractor Works

A honey extractor is a simple yet powerful machine designed for a single purpose: separating liquid honey from the beeswax comb without destroying it.

The Principle of Centrifugal Force

The extractor is essentially a large drum with a basket inside that holds honey frames. When the basket is spun, either by a hand crank or an electric motor, it generates powerful centrifugal force.

This force flings the liquid honey outwards from the comb cells against the inner wall of the drum. The honey then runs down the wall and pools at the bottom, ready to be collected.

Manual vs. Electric Extractors

Manual extractors are operated with a hand crank. They are ideal for hobbyists or small-scale beekeepers with only a few hives, offering a lower-cost and simpler solution.

Electric extractors use a motor to spin the basket, making the process much faster and less physically demanding. These are preferred for larger or commercial operations where efficiency is critical.

The Step-by-Step Extraction Process

A successful harvest is a systematic process that begins before the extractor is ever turned on. Follow these steps for a clean and efficient extraction.

Step 1: Remove and Prepare Frames

Your first task is to remove the frames of capped honey from the hive. Bees seal each cell of ripened honey with a thin layer of beeswax, known as "capping." This must be removed for the honey to flow out.

Step 2: Uncap the Honeycomb

Using a specialized uncapping knife (often heated), an uncapping fork, or even a serrated bread knife, slice off the top layer of wax cappings. The goal is to expose the liquid honey in the cells beneath with minimal damage to the comb structure.

Step 3: Load the Extractor

Place the uncapped frames into the baskets or slots inside the extractor. Ensure they are well-balanced to prevent the machine from shaking violently during operation.

Step 4: Spin the Frames

Begin spinning the extractor. Start slowly and gradually increase speed. Spin for a short period (around 30-60 seconds), then stop.

Because only one side of the comb is facing outwards, you must now flip the frames to extract honey from the opposite side. Spin them again for a similar duration. This two-step spinning process ensures you extract all the honey.

Step 5: Drain and Strain the Honey

Once the spinning is complete, the raw honey will have collected at the bottom of the extractor. Open the spigot or honey gate at the bottom of the drum and let the honey flow out into a food-grade bucket.

It is critical to strain the honey through a fine mesh filter or cheesecloth as it flows. This will remove any bits of beeswax, bee parts, or other debris.

Understanding the Trade-offs and Best Practices

Using an extractor is the industry standard, but understanding the alternatives and post-extraction steps reveals why it is the superior method for sustainable beekeeping.

Why You Must Return "Wet" Frames

After extraction, the frames are empty of honey but still coated in a sticky residue. These are known as "wet" frames.

Returning these frames to the hive is a crucial final step. The bees will quickly clean every last drop of honey and, most importantly, immediately begin refilling the intact comb. This saves them the significant energy it would take to build new comb from scratch.

The Alternative: The "Crush and Strain" Method

For those without an extractor, the only other method is to "crush and strain." This involves scraping the entire comb into a bucket, mashing it to release the honey, and then straining the mixture.

While effective, this method completely destroys the comb. The bees must expend enormous resources to rebuild it, significantly slowing down future honey production. Using an extractor avoids this major setback.

Making the Right Choice for Your Goal

Your choice of equipment and process depends entirely on your objectives as a beekeeper.

- If your primary focus is preserving your comb for reuse: Using a honey extractor is the only method that leaves the delicate beeswax structure intact.

- If your primary focus is maximum efficiency for a large harvest: An electric, multi-frame extractor is the essential tool for processing many frames quickly.

- If your primary focus is the highest purity honey: A double-straining process, using coarse and then fine filters, is a non-negotiable step to ensure a final product free of all wax and debris.

Ultimately, mastering the extraction process transforms you from simply keeping bees to becoming a true honey harvester.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Prepare Frames | Remove capped honey frames from the hive. | Access the honey for extraction. |

| 2. Uncap Comb | Slice off wax cappings with an uncapping knife. | Expose the liquid honey in the cells. |

| 3. Load Extractor | Place uncapped frames into the extractor's basket. | Prepare for the centrifugal spinning process. |

| 4. Spin Frames | Spin the extractor, flip frames, and spin again. | Use centrifugal force to pull honey from the comb. |

| 5. Drain & Strain | Drain honey through a spigot and filter it. | Collect pure, debris-free honey for storage. |

Ready to streamline your honey harvest and boost your apiary's productivity?

For commercial apiaries and beekeeping equipment distributors, efficient extraction is key to scaling your operation. HONESTBEE supplies high-quality, durable honey extractors and the full suite of beekeeping supplies you need for a successful harvest.

Let us help you equip your business for maximum efficiency and honey yield.

Contact HONESTBEE today to discuss your wholesale needs and discover the right equipment for your goals!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the pressing method for extracting honey? A Simple, Low-Cost Approach for Small-Scale Beekeepers

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- How do you manually extract honey? Choose the Best Method for Your Hive

- How much honey does a beekeeper extract from the hive? A Guide to Sustainable Harvesting

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper