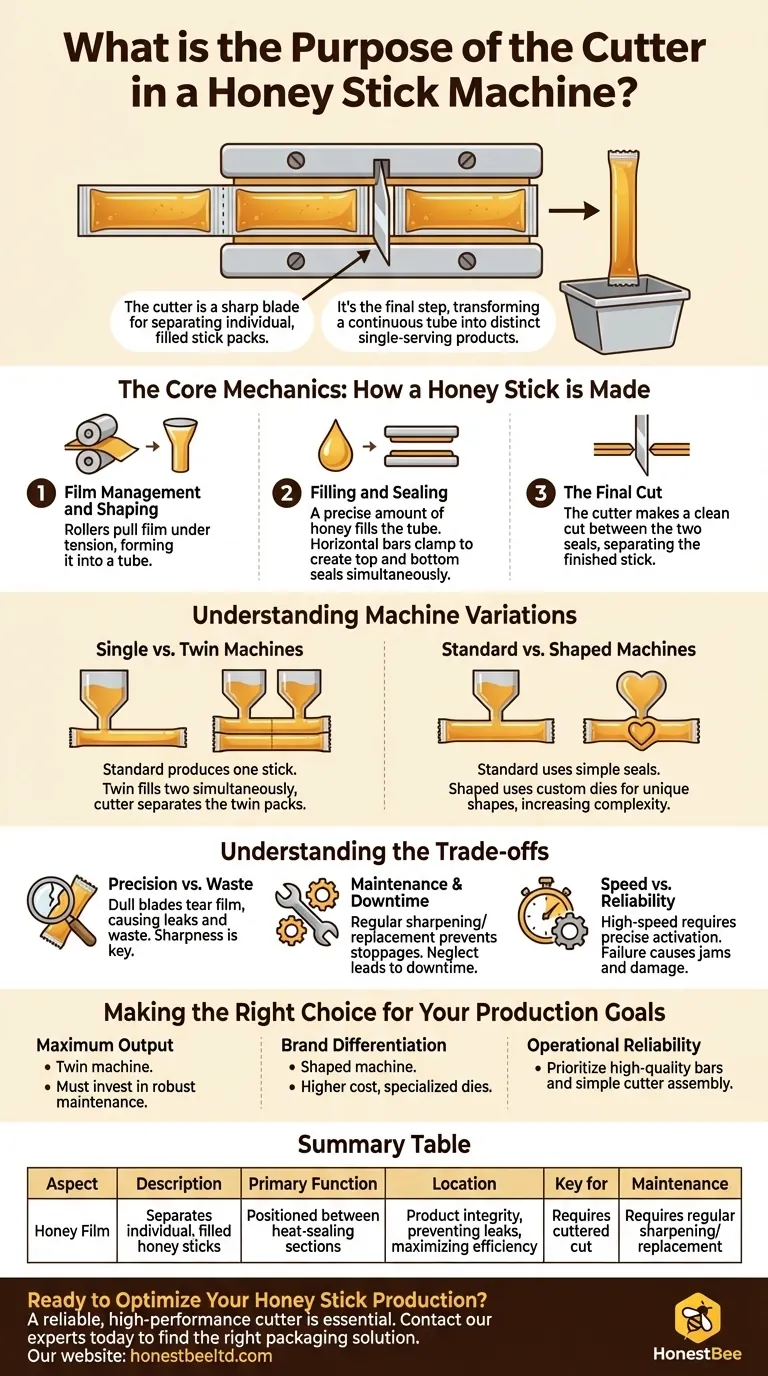

At its core, the cutter in a honey stick machine is a sharp blade responsible for separating individual, filled stick packs from each other. This blade is typically located in the middle of the horizontal sealing bar, which clamps down to seal the sticks. The cutter's action is the final step that transforms a continuous tube of honey-filled film into distinct, single-serving products.

The cutter may seem like a minor component, but its function is the critical endpoint of the entire automated packaging process. To truly understand its purpose is to understand the full journey from a flat roll of film to a finished, saleable honey stick.

The Core Mechanics: How a Honey Stick is Made

A honey stick machine executes a series of highly synchronized steps. The cutter's role is best understood as the final action in this sequence.

Step 1: Film Management and Shaping

The process begins with a large roll of packaging film. A system of rollers, including nip rollers, pulls the film into the machine, keeping it under constant tension.

This tension is critical for preventing wrinkles and ensuring the film feeds smoothly, which in turn helps prevent spills during the filling stage. The flat film then passes through a forming tube, a conical device that folds it into the familiar cylindrical stick shape.

Step 2: Filling and Sealing

As the newly formed tube of film moves downwards, it is filled with a precise amount of honey from a hopper.

Immediately after filling, a pair of horizontal sealing bars clamp together. These bars use heat and pressure to create two seals simultaneously: the top seal of the just-filled stick and the bottom seal of the next stick to be filled.

Step 3: The Final Cut

This is where the cutter performs its essential function. Positioned directly between the two heat-sealing sections on the horizontal bar, the cutter activates.

It makes a clean, precise cut through the middle of the sealed area, separating the finished honey stick from the continuous film above it. The completed stick then drops into a collection bin, ready for packaging.

Understanding Machine Variations

While the basic process is consistent, different machine types utilize the cutting mechanism to achieve different production goals.

Single vs. Twin Machines

A standard machine produces one stick at a time. A twin honey stick machine, however, uses two hoppers to fill two attached stick packs simultaneously.

In this setup, the cutter separates the twin packs from the film roll, and often a secondary cutter or process separates the two sticks from each other. This design dramatically increases production efficiency.

Standard vs. Shaped Machines

Some machines are designed to create unique shapes, like hearts or stars, on the seals to improve marketability.

A shaped honey stick machine uses custom-designed sealing and cutting dies. The fundamental purpose of the cutter remains the same—separation—but it must follow a more intricate path, adding to the machine's complexity and cost.

Understanding the Trade-offs

The cutter's performance is directly linked to production quality and efficiency. Its simple function comes with critical considerations.

Precision vs. Waste

The cutter's blade must be perfectly sharp and aligned. A dull or misaligned blade will tear the plastic film instead of cutting it, leading to poorly sealed sticks, product leakage, and wasted material.

Maintenance and Downtime

As a mechanical component in constant use, the cutter is a point of wear. The blade will dull over time and require regular sharpening or replacement. Neglecting this maintenance is a primary cause of production stoppages and decreased output.

Speed vs. Reliability

In high-speed operations, the cutter must activate and retract with extreme speed and precision. A failure in the cutting mechanism at high speed can cause jams, damage other components like the sealing bars, and lead to significant downtime.

Making the Right Choice for Your Production Goals

Aligning your machine's capabilities with your primary business objective is essential for success. The cutter is a key part of this equation.

- If your primary focus is maximum output: A twin honey stick machine is the clear choice, but you must invest in a robust maintenance schedule for its more complex cutting system.

- If your primary focus is brand differentiation: A shaped honey stick machine provides a unique product, but be prepared for the higher initial cost and the need for specialized cutting dies.

- If your primary focus is operational reliability: Prioritize a machine with high-quality, durable sealing bars and a simple, easily accessible cutter assembly to minimize maintenance-related downtime.

Ultimately, a well-maintained cutter is the key that unlocks efficient, waste-free production and delivers a perfect final product every time.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Separates individual, filled honey sticks from a continuous tube of film. |

| Location | Positioned between the heat-sealing sections on the horizontal sealing bar. |

| Key for | Product integrity, preventing leaks, and maximizing production efficiency. |

| Maintenance | Requires regular sharpening/replacement to avoid tearing film and downtime. |

Ready to Optimize Your Honey Stick Production?

A reliable, high-performance cutter is essential for creating perfect, leak-free honey sticks. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, precision-engineered honey stick machines and replacement parts they need to maximize output and minimize waste.

Contact our experts today to find the right packaging solution for your production goals, from high-speed twin machines to specialized shaped models.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the benefits of using proper honey bottling equipment? Elevate Your Product Quality and Profitability

- What function do automated Honey-filling Machines serve? Boost Commercial Honey Quality and Brand Consistency

- What is the value of automated honey-filling equipment for commercial pollination operations? Boost Output and Efficiency

- What is the best use case for gravity filling machines? Bottle Thin Liquids with Unmatched Simplicity

- How do you fill a sachet bag? A Step-by-Step Guide to Perfectly Filled Fragrant Sachets

- How does a piston honey filler work? Master Precision Filling for Viscous Honey and Commercial Jars

- How does automatic honey filling and processing equipment contribute to the integrity of organic honey production?

- What sizes of jars and containers can the filling machine accommodate? Versatile Solutions for Every Packaging Size