At its core, an electric honey extractor automates the most labor-intensive part of harvesting honey. By using an electric motor to spin frames, it employs centrifugal force to separate honey from the comb with remarkable speed and minimal physical effort from the beekeeper. This automation makes it an essential tool for anyone processing honey from more than just one or two backyard hives.

The decision to use an electric honey extractor is fundamentally about valuing time and labor. While manual methods work, an electric model offers a significant leap in efficiency, allowing a beekeeper to process much larger volumes of honey far more quickly and with less physical strain.

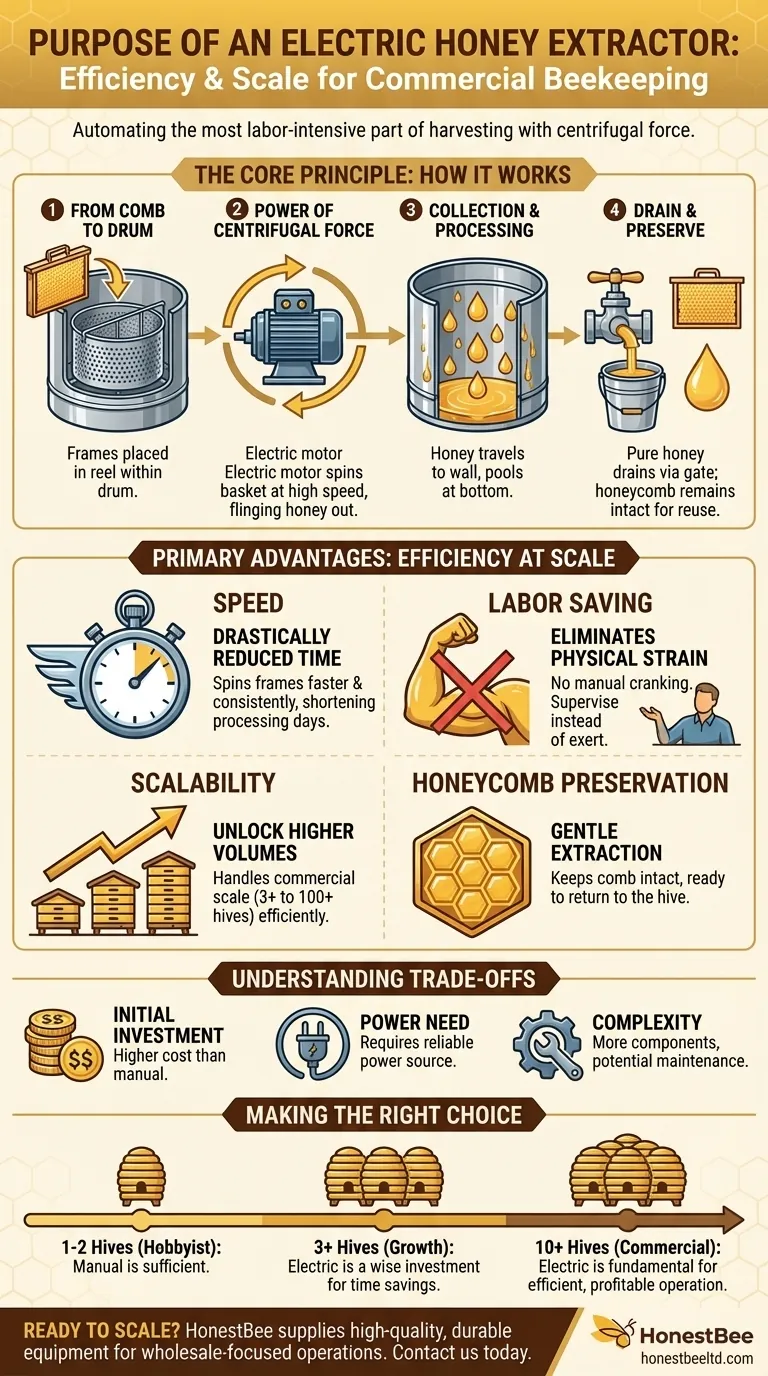

The Core Principle: How an Electric Extractor Works

An electric extractor operates on a simple yet powerful physical principle. Understanding its mechanics clarifies its purpose as a tool for efficiency.

From Comb to Drum

The process begins after the wax cappings are removed from a frame of honeycomb. The beekeeper places these frames vertically into a basket or "reel" inside a large stainless steel drum. This basket is connected to a central rod, which is turned by an electric motor.

The Power of Centrifugal Force

With the flip of a switch, the motor begins to spin the basket. As the speed increases, powerful centrifugal force flings the liquid honey out of the comb's cells. The honey travels outward and strikes the interior wall of the drum.

Collection and Processing

The extracted honey then runs down the drum's inner wall and pools at the bottom. A valve, often called a honey gate, allows the beekeeper to easily drain the pure, filtered honey into buckets for bottling or further processing. The honeycomb itself remains intact within the frame, ready to be returned to the hive.

The Primary Advantage: Efficiency at Scale

The true purpose of an electric extractor is revealed when you compare its output to manual methods. The benefits are most apparent as the number of hives increases.

Drastically Reduced Extraction Time

An electric motor can spin frames far faster and more consistently than a person can with a hand crank. This allows you to extract all the honey from a set of frames in a fraction of the time, dramatically shortening your processing day.

Eliminating Physical Strain

Manually cranking a honey extractor for hours is physically demanding work. An electric model removes this strenuous labor entirely. The process becomes one of supervision rather than manual exertion, saving your back and arms from fatigue.

Unlocking Higher Volumes

Electric extractors are built for scale. While small models may hold only two to four frames, commercial versions can process over 100 deep frames in a single run. This capability makes them indispensable for small, medium, and large-scale apiaries that need to harvest significant quantities of honey efficiently.

Understanding the Trade-offs

While highly effective, an electric extractor is not the default choice for every beekeeper. Being a trusted advisor means acknowledging the practical considerations.

The Initial Investment

The most significant barrier is cost. Electric extractors are considerably more expensive than their manual counterparts. This upfront investment may not be justifiable for a beekeeper with only one or two hives who harvests a small amount of honey each year.

The Need for Power

As the name implies, an electric extractor requires a reliable power source. For beekeepers who extract honey in a remote shed, barn, or off-grid location, this can pose a logistical challenge that must be solved with generators or battery systems.

Increased Complexity and Maintenance

An electric motor and its associated controls add a layer of complexity. These components can potentially fail and may require troubleshooting or repair, whereas a manual extractor is a much simpler mechanical device with fewer points of failure.

Making the Right Choice for Your Apiary

Your decision should be guided by the scale of your operation and your personal goals.

- If your primary focus is the hobbyist experience (1-2 hives): A manual extractor is often sufficient and more economical, allowing you to enjoy the hands-on process without a large investment.

- If your primary focus is growth and time savings (3+ hives): An electric extractor is a wise investment that will immediately pay for itself in saved time and physical labor.

- If your primary focus is commercial production (10+ hives): An electric extractor is not a luxury; it is a fundamental piece of equipment necessary for an efficient and profitable operation.

Ultimately, an electric honey extractor empowers you to scale your passion for beekeeping beyond the limits of manual labor.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed | Drastically reduces extraction time compared to manual cranking. |

| Labor Saving | Eliminates physical strain, turning work into supervision. |

| Scalability | Enables efficient processing of honey from 3 to 100+ hives. |

| Honeycomb Preservation | Gently extracts honey while keeping the comb intact for reuse. |

Ready to scale your honey production efficiently?

For commercial apiaries and beekeeping equipment distributors, an electric honey extractor is a cornerstone of a profitable operation. HONESTBEE supplies high-quality, durable beekeeping equipment designed for wholesale-focused operations like yours.

Contact HONESTBEE today to discuss your needs and discover how our electric honey extractors and other supplies can enhance your efficiency and bottom line.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How does the implementation of automated honey-filling machines address the challenge of rising production costs? Achieve Scalability and Precision

- What is the significance of automated honey-filling machinery? Protect Your Harvest from Small Hive Beetle Spoilage

- What is the role of Automated Honey-filling Machines? Scale Your Honey Brand with Precision and Safety

- How do industrial honey filling machines protect the biological activity of honey? Ensure Nutritional Integrity

- What are the economic benefits of automated honey filling systems? Boost ROI in Large-Scale Commercial Apiaries