Ultimately, very little active maintenance is required for a honey extractor. The core responsibilities are thorough cleaning after every use and a quick inspection of key mechanical components before you begin. For most units, especially manual ones, the design is simple and built for longevity.

The single most important aspect of honey extractor maintenance is not a mechanical tune-up, but a rigorous cleaning process after each harvest. This prevents contamination, deters pests, and ensures the machine is ready for the next season.

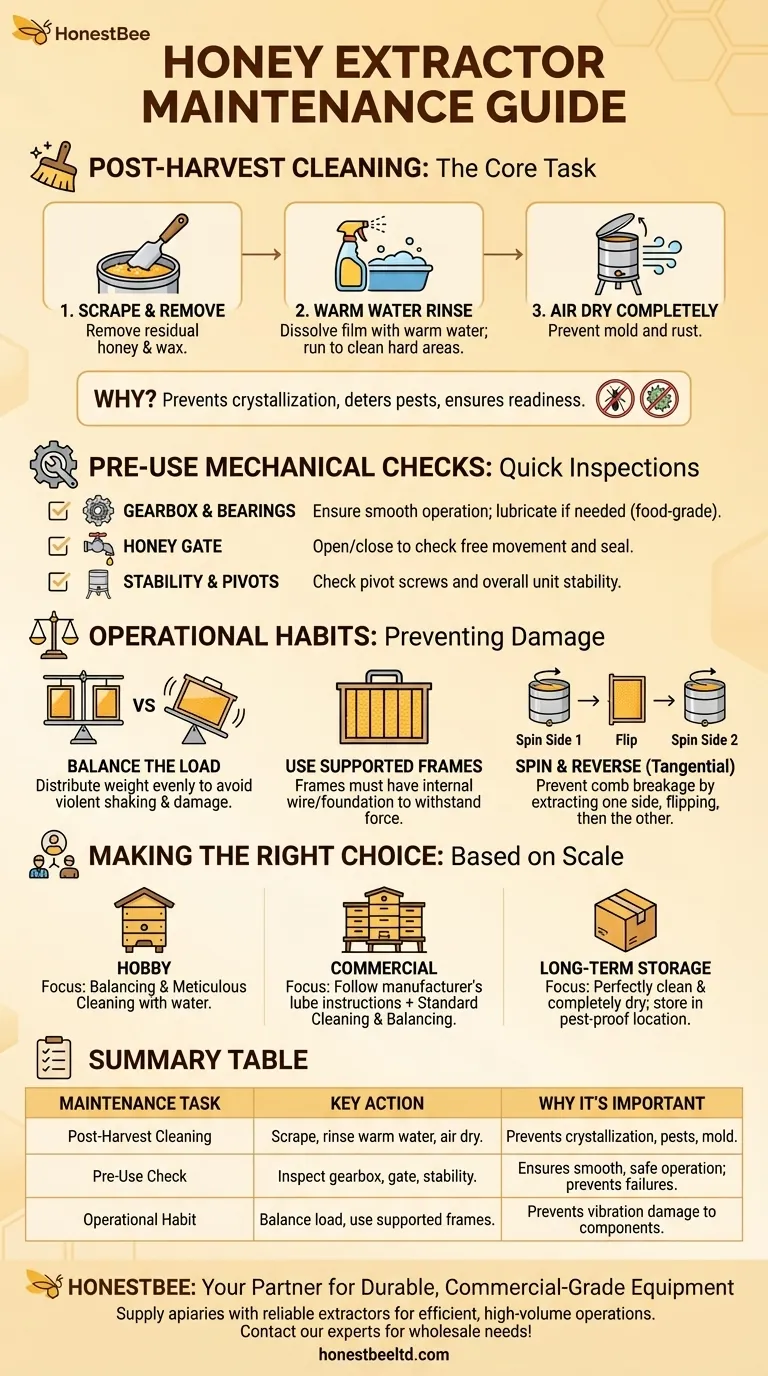

The Core Maintenance Task: Post-Harvest Cleaning

Proper cleaning is not just about hygiene; it's preventative maintenance. Hardened honey and wax can seize moving parts and make future extractions difficult.

Why Cleaning is Non-Negotiable

Failing to clean your extractor immediately after use allows honey residue to crystallize. This hardened sugar is extremely difficult to remove and can attract pests or promote the growth of mold.

A Step-by-Step Cleaning Process

The most effective method uses little more than water. First, use a spatula to scrape out as much residual honey and wax as possible.

Next, dissolve the remaining honey film with clean, warm water. You can spray the interior walls and basket, letting the water collect at the bottom. For stubborn spots, run the extractor with the water inside, using centrifugal force to clean hard-to-reach areas. Drain, rinse, and let it air dry completely.

Pre-Use Mechanical Checks

Before you load your first frame, a quick inspection can prevent a major headache during your harvest. These checks take only a few minutes.

Inspect the Gearbox and Bearings

For both manual and motorized units, ensure the gearbox and any bearings are in good condition. They should operate smoothly without grinding or excessive noise. If they feel stiff, consult your manufacturer's guide, as some models may require food-grade lubricant.

Verify the Honey Gate

The honey gate is the valve at the bottom of the extractor. Open and close it a few times to ensure it moves freely and seals properly. A leaking gate is a significant problem during a long extraction session.

Check the Pivot Screw and Stability

Ensure any central pivot screws are secure. The entire unit should be stable on the floor or its stand. During operation, the machine will generate powerful forces, and stability is critical for safety and performance.

Operational Habits That Prevent Damage

How you use your extractor is a form of maintenance. Improper operation is the leading cause of damage.

Always Balance the Load

An unbalanced load is the most common way to damage an extractor. As it spins, uneven weight distribution will cause violent shaking that can damage the basket, bearings, and motor.

Always load frames of similar weight directly across from one another to maintain balance. Start spinning slowly to confirm the load is even before increasing the speed.

Only Use Supported Frames

Do not place frames that lack internal wire or plastic foundation into an extractor. The centrifugal force is strong enough to tear the unsupported comb apart, creating a major mess and potentially damaging the basket.

Spin and Reverse Correctly

For tangential extractors, spin the frames for several minutes to extract honey from the first side. Then, flip the frames and spin again to extract from the second side. This two-step process prevents the weight of honey on the un-extracted side from breaking the comb.

Making the Right Choice for Your Goal

Your maintenance routine will be dictated by the scale of your operation and the type of equipment you own.

- If your primary focus is a small, hobby-level harvest: Your main tasks are balancing the frames during use and meticulously cleaning the extractor with water afterward.

- If your primary focus is a larger or commercial operation: You must adhere to the manufacturer's instructions for lubricating the motor or gearbox, in addition to standard cleaning and balancing procedures.

- If your primary focus is long-term storage: Your goal is to ensure the extractor is perfectly clean and completely dry before storing it in a sealed, pest-proof location.

A well-maintained extractor is a reliable partner in every successful honey harvest.

Summary Table:

| Maintenance Task | Key Action | Why It's Important |

|---|---|---|

| Post-Harvest Cleaning | Scrape, rinse with warm water, and air dry. | Prevents crystallization, pest attraction, and mold growth. |

| Pre-Use Mechanical Check | Inspect gearbox, bearings, honey gate, and stability. | Ensures smooth, safe operation and prevents mid-harvest failures. |

| Operational Habit | Always balance the load and use supported frames. | Prevents damage to the basket, bearings, and motor from vibration. |

Ensure your honey harvests run smoothly for years to come with durable, commercial-grade equipment from HONESTBEE. We supply apiaries and distributors with the reliable extractors and supplies needed for efficient, high-volume operations. Let our experts help you choose the right equipment for your scale. Contact HONESTBEE today to discuss your wholesale needs!

Visual Guide

Related Products

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

People Also Ask

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What mistakes should be avoided during honey extraction with a centrifuge? Preserve Your Comb and Honey Quality

- What were the initial designs of the honey extractor like? From Hand-Swung Tin Box to Modern Machine

- How to get honey out of a frame? Choose Between Crush & Strain or Centrifugal Extraction

- How do beekeepers harvest honey from the honey super? A Step-by-Step Guide to Efficient Extraction