The standard material for bee frame wire is 304 stainless steel. This specific alloy is chosen for its exceptional durability, strength, and critical resistance to corrosion, ensuring it can withstand the unique environment inside a beehive for years without degrading.

The choice of 304 stainless steel is not arbitrary; it is a deliberate decision to protect the structural integrity of the honeycomb and the purity of the honey itself from rust and contamination.

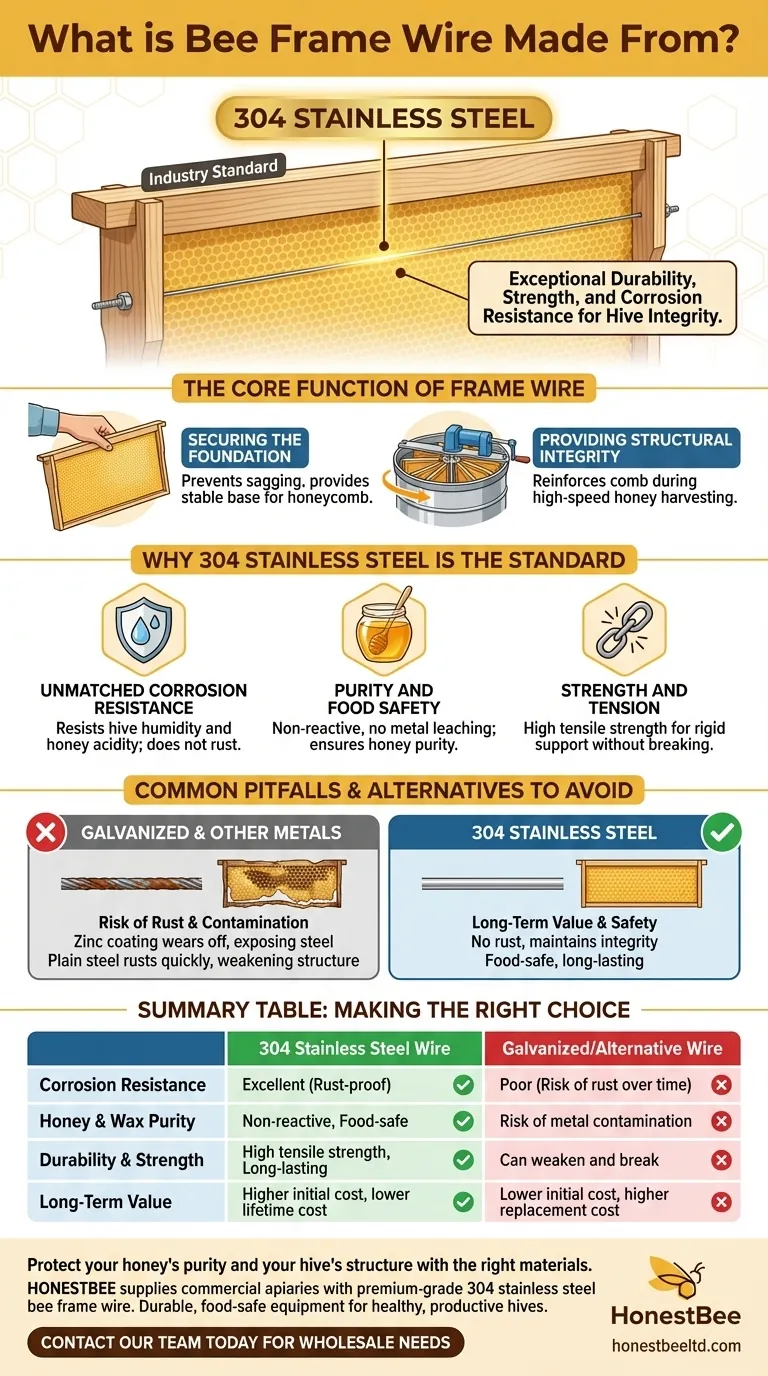

The Core Function of Frame Wire

Before examining the material, it's essential to understand why this wire is used in the first place. Bee frame wire, also called foundation wire, serves two primary purposes that are critical for modern beekeeping.

Securing the Foundation

The wire is threaded through the wooden frame and embedded into a sheet of beeswax or plastic foundation. This secures the foundation, preventing it from sagging or warping, and provides a stable base for the bees to build their honeycomb.

Providing Structural Integrity

The wire acts as a reinforcement skeleton within the wax. This added strength is crucial during honey harvesting, when frames are spun at high speeds in an extractor to remove the honey. Without wire, the delicate comb would disintegrate under the force.

Why 304 Stainless Steel is the Industry Standard

The environment inside a beehive is warm and humid, and honey itself is slightly acidic. This combination creates a highly corrosive environment, making material selection paramount.

Unmatched Corrosion Resistance

The primary advantage of 304 stainless steel is its excellent resistance to rust and corrosion. It will not break down over time, ensuring the wire remains strong season after season.

Purity and Food Safety

Because stainless steel is non-reactive, it will not leach any metals or chemicals into the beeswax or honey. This is a crucial consideration for beekeepers, as honey is a food product where purity is essential.

Strength and Tension

Stainless steel has the high tensile strength needed to be pulled taut without breaking. This tension is necessary to provide a rigid and effective support structure for the foundation.

Common Pitfalls and Alternatives to Avoid

While 304 stainless steel is the recommended material, other types of wire exist. However, they come with significant trade-offs that can impact your hive's health and your honey's quality.

The Risk of Galvanized Steel

Galvanized wire is steel coated in a layer of zinc to prevent rust. While cheaper, this zinc coating can eventually wear away, exposing the steel underneath to the hive's moisture and leading to rust, which can weaken the wire and potentially contaminate the honey.

The Problem with Other Metals

Using other metals like plain steel or iron wire is not recommended. They will rust very quickly inside the hive, creating a weak structure and compromising the quality of your honey and wax.

Making the Right Choice for Your Hive

Selecting the correct wire is a small but critical decision that affects the long-term health of your colony and the quality of your harvest.

- If your primary focus is longevity and honey purity: Always choose 304 stainless steel wire. It is the safest, most durable, and most reliable option available.

- If you are considering a cheaper alternative: Understand that options like galvanized wire introduce a long-term risk of rust and potential contamination, requiring more frequent frame replacement.

Investing in the right material from the start ensures your equipment supports, rather than hinders, a healthy and productive hive.

Summary Table:

| Feature | 304 Stainless Steel Wire | Galvanized/Alternative Wire |

|---|---|---|

| Corrosion Resistance | Excellent (Rust-proof) | Poor (Risk of rust over time) |

| Honey & Wax Purity | Non-reactive, Food-safe | Risk of metal contamination |

| Durability & Strength | High tensile strength, Long-lasting | Can weaken and break |

| Long-Term Value | Higher initial cost, lower lifetime cost | Lower initial cost, higher replacement cost |

Protect your honey's purity and your hive's structure with the right materials.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with premium-grade 304 stainless steel bee frame wire. Our wholesale-focused operations ensure you get durable, food-safe equipment that supports a healthy, productive hive season after season.

Ready to equip your operation with the best? Contact our team today to discuss your wholesale needs.

Visual Guide

Related Products

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Multi-Function Frame Grip with Integrated Hive Tool

- Professional Pneumatic Wire Embedder for Beehive Frames

- Manual Spur Wheel Wire Embedder for Foundation

- Professional Adjustable Timer Electric Wire Embedder

People Also Ask

- How do wooden frames perform during honey extraction? Superior Rigidity for a Smoother Harvest

- What are bee frames, and how do they relate to box sizes? A Guide to the Langstroth Hive System

- How many frames fit in a 10 frame hive? A Guide to Maximizing Your Hive's Potential

- Can I reuse old frames? A practical guide to saving money and reducing waste

- When should I throw away my bee frame? A Guide to Hive Health & Frame Rotation