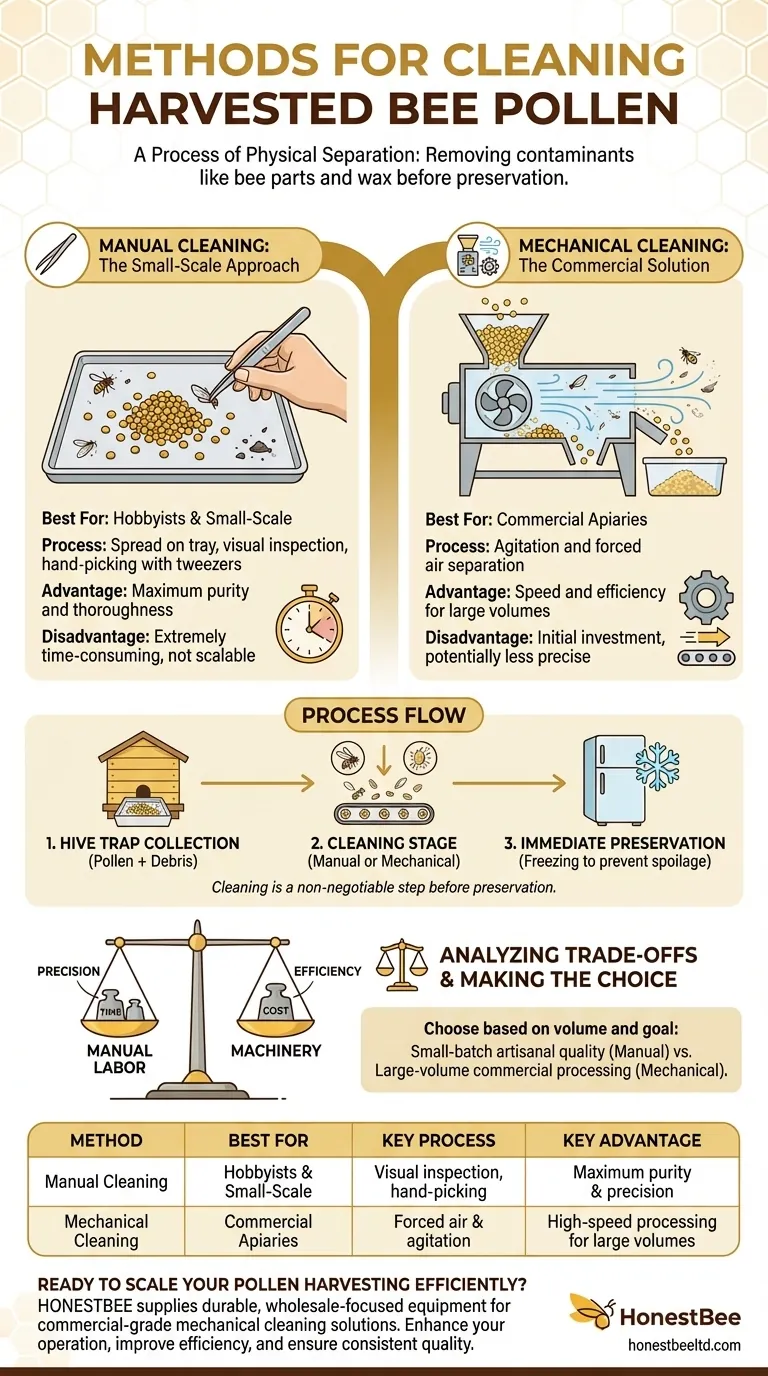

At its core, cleaning harvested bee pollen is a process of physical separation. The two primary methods are manual inspection for small-scale operations and a mechanical approach using air and agitation for commercial volumes. Both methods aim to remove foreign debris like bee parts, wax, or hive beetles before the pollen is preserved.

The goal of cleaning bee pollen is to remove all visible, non-pollen contaminants. Your choice of method—either careful manual picking or efficient mechanical sorting—depends entirely on the volume you need to process.

The Two Philosophies of Pollen Cleaning

The method you use to clean bee pollen is a direct function of your operational scale. What works for a hobbyist is impractical for a commercial producer, and vice versa.

H3: Manual Cleaning: The Small-Scale Approach

For hobbyists or small-scale beekeepers, manual cleaning is the most straightforward method. The process is simple and requires no specialized equipment.

You begin by spreading the harvested pollen in a thin layer on a flat tray or a screen. This allows you to see everything clearly.

Under good lighting, you can then visually inspect the pollen and pick out any debris. Common contaminants include bee wings, legs, bits of wax, or small beetles.

Using tweezers can be extremely helpful for removing these tiny, unwanted materials with precision.

H3: Mechanical Cleaning: The Commercial Solution

For larger, commercial operations, manual cleaning is not feasible. Instead, producers use equipment that functions similarly to seed cleaners.

This method relies on a combination of agitation and forced air. A fan is used to create a current of air that blows away lighter debris like dust and bee wings.

The heavier, denser bee pollen pellets are not blown away and are separated from the lighter waste. Agitation helps to break up clumps and ensure all debris is exposed to the air current.

Understanding the Process Flow

Cleaning is a critical step, but it's only one part of preparing bee pollen for its final use. Understanding its place in the overall workflow is key to producing a high-quality product.

H3: From the Trap to the Tray

Pollen is collected in traps at the hive entrance. This collection method inevitably gathers more than just pollen, which is why the cleaning step is non-negotiable.

H3: After Cleaning: Immediate Preservation

Once the pollen is clean, the clock is ticking. It must be frozen immediately to preserve its freshness, nutritional value, and prevent spoilage. Cleaning is the final preparatory step before preservation.

Analyzing the Trade-offs

Each cleaning method comes with distinct advantages and disadvantages that make it suitable for different goals.

H3: The Precision of Manual Labor

The primary benefit of manual cleaning is its thoroughness. You can achieve an exceptionally high level of purity by inspecting every grain.

However, this method is extremely time-consuming and does not scale. It is only practical for very small batches.

H3: The Efficiency of Machinery

Mechanical cleaners are valued for their speed and efficiency. They can process large quantities of pollen in a fraction of the time it would take to do manually.

The main drawback is the initial investment in equipment. Additionally, a mechanical cleaner may not be as precise as the human eye and could miss some contaminants.

Making the Right Choice for Your Goal

Your primary objective determines the correct cleaning method. Consider the volume of your harvest and your desired end product.

- If your primary focus is small-batch, artisanal quality: Manual cleaning is the best method to ensure the highest purity for personal use or a small customer base.

- If your primary focus is processing large volumes efficiently for sale: Investing in a mechanical pollen cleaner is the only practical way to handle a commercial-scale harvest.

Ultimately, a commitment to cleanliness is what ensures a safe, valuable, and high-quality final bee pollen product.

Summary Table:

| Method | Best For | Key Process | Key Advantage |

|---|---|---|---|

| Manual Cleaning | Hobbyists & Small-Scale | Visual inspection and hand-picking debris | Maximum purity and precision |

| Mechanical Cleaning | Commercial Apiaries | Using forced air and agitation to separate debris | High-speed processing for large volumes |

Ready to scale your pollen harvesting efficiently?

For commercial apiaries and beekeeping equipment distributors, choosing the right cleaning method is crucial for productivity and product quality. HONESTBEE supplies the durable, wholesale-focused equipment you need to implement a commercial-grade mechanical cleaning solution.

Let us help you enhance your operation:

- Source reliable equipment for high-volume pollen processing.

- Improve your efficiency and output with tools built for scale.

- Ensure a consistent, high-quality product for your market.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

People Also Ask

- What percentage of pollen pellets can a typical pollen trap collect? Optimize Your Harvest & Hive Health

- What are the functions and benefits of using Professional Pollen Traps? Maximize Your Apiary’s Revenue Streams

- What is the function of industrial-grade dehydration equipment in bee pollen processing? Preserve Quality and Potency

- What role do exogenous pollen pots play in inducing stingless bee honey production? Maximize Yields & Growth

- Why is the supplementation of pollen substitutes necessary when employing pollen traps for large-scale collection?

- Why is a precision-controlled electric drying oven necessary for bee pollen? Preserve Nutrients & Ensure Safety

- How do pollen traps facilitate the efficient collection of bee pollen? Optimize Your Industrial Bee Product Harvest

- What role does a pollen trap play in the systematic harvesting of bee pollen? Optimize Your Commercial Yield