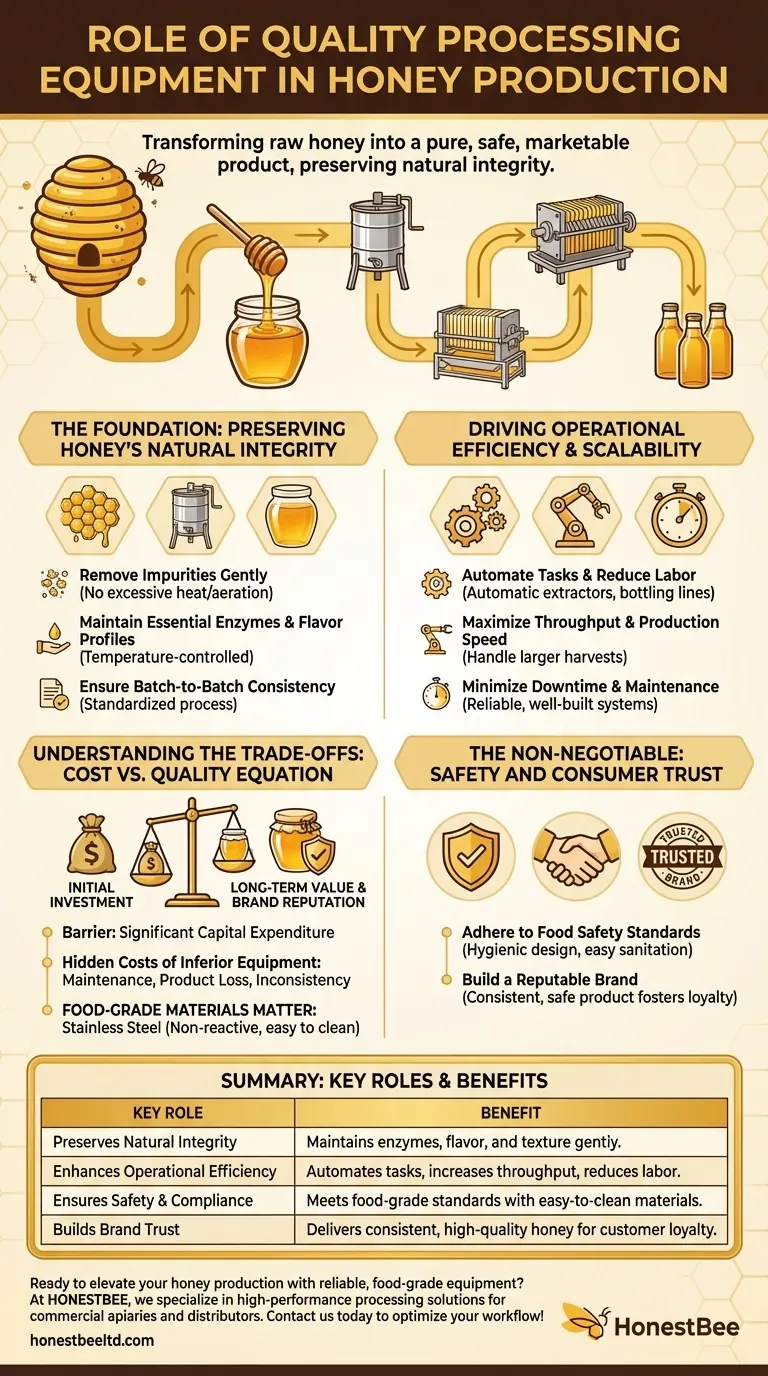

At its core, quality processing equipment is the critical link that transforms raw honey from the hive into a pure, safe, and marketable product. This equipment is responsible for extracting, filtering, and preparing the honey, directly ensuring it remains free from impurities while preserving its natural enzymes, texture, and flavor.

Investing in quality processing equipment is not simply about efficiency; it's a foundational decision that dictates product quality, ensures consumer safety, and ultimately builds the trust and reputation of your brand.

The Foundation: Preserving Honey's Natural Integrity

The primary goal of honey processing is to clean and prepare the honey without stripping it of the natural characteristics that make it valuable.

Removing Impurities Without Compromising Quality

High-quality extractors and filtration systems are designed to effectively remove physical impurities like wax cappings, bee parts, and other hive debris. The key is to do this gently, without introducing excessive heat or aeration that can degrade the honey.

Maintaining Essential Enzymes and Flavor Profiles

Honey contains beneficial enzymes and delicate aromatic compounds that are sensitive to heat and agitation. Superior equipment, particularly temperature-controlled tanks and gentle pumps, helps preserve these natural qualities, ensuring the final product retains its unique flavor and health benefits.

Ensuring Batch-to-Batch Consistency

For any commercial operation, consistency is paramount. Quality processing equipment standardizes the process, from extraction speed to filtration level, resulting in a reliable final product. This ensures that every jar has the same texture, clarity, and quality that customers expect.

Driving Operational Efficiency and Scalability

Beyond quality, the right equipment is a powerful driver of business viability, reducing manual effort and enabling growth.

Automating Tasks and Reducing Labor

Modern systems, such as automatic extractors and bottling lines, significantly reduce the need for manual labor. This automation speeds up the entire process, freeing up personnel for other critical tasks within the operation.

Maximizing Throughput and Production Speed

Efficient equipment processes more honey in less time. This increased throughput allows producers to handle larger harvests without creating bottlenecks, directly increasing overall production capacity and scalability.

Minimizing Downtime and Maintenance

Reliable, well-built equipment minimizes the risk of unexpected breakdowns during the critical harvest and processing season. Less downtime means more consistent productivity and reduced maintenance costs over the long term.

Understanding the Trade-offs: The Cost vs. Quality Equation

While the benefits are clear, the initial investment can seem daunting. It's crucial to look beyond the sticker price.

The Initial Investment Barrier

There is no question that high-quality, food-grade processing equipment represents a significant capital expenditure. This can be a major hurdle for new or smaller-scale beekeepers.

The Hidden Costs of Inferior Equipment

Opting for cheaper, lower-quality equipment often leads to higher long-term costs. These include frequent maintenance, product loss from inefficient extraction, inconsistent quality that hurts brand reputation, and the serious risk of failing to meet food safety standards.

Why Food-Grade Materials Matter

Professional honey processing equipment is typically made from food-grade stainless steel. This material is non-reactive, preventing any leaching of metals into the honey, and is easy to clean and sanitize, which is essential for preventing contamination.

The Non-Negotiable: Safety and Consumer Trust

Ultimately, all processing choices impact the person who consumes the honey.

Adhering to Food Safety Standards

Quality equipment is designed with hygiene in mind. Smooth welds, easy disassembly, and non-porous surfaces are critical for proper cleaning and sanitation, ensuring you can meet and exceed local health and safety regulations.

Building a Reputable Brand

A consistent, high-quality, and safe product is the cornerstone of a trusted brand. When customers know they can rely on your honey, you build loyalty that translates directly into repeat business and a strong market position.

Making the Right Choice for Your Operation

The "best" equipment depends entirely on your specific goals.

- If your primary focus is boutique, artisanal quality: Prioritize equipment that offers gentle handling and minimal, coarse filtration to preserve the maximum amount of pollen and natural character.

- If your primary focus is commercial scale and efficiency: Invest in automated, high-throughput systems that ensure consistency, reduce labor costs, and can grow with your operation.

- If your primary focus is safety and starting strong: Begin with a foundational set of food-grade stainless steel equipment (extractor, tank) that guarantees safety and can be expanded upon later.

Your processing equipment is the final guardian of the bees' hard work, ensuring it reaches the customer with its integrity intact.

Summary Table:

| Key Role | Benefit |

|---|---|

| Preserves Natural Integrity | Maintains enzymes, flavor, and texture by removing impurities gently. |

| Enhances Operational Efficiency | Automates tasks, increases throughput, and reduces labor costs. |

| Ensures Safety & Compliance | Meets food-grade standards with easy-to-clean, non-reactive materials. |

| Builds Brand Trust | Delivers consistent, high-quality honey that fosters customer loyalty. |

Ready to elevate your honey production with reliable, food-grade equipment?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance processing solutions—from stainless steel extractors to automated bottling lines. Our wholesale-focused operations ensure you get durable, scalable equipment that protects your honey's quality and grows your business.

Contact us today to discuss your needs and discover how our expertise can optimize your workflow!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

People Also Ask

- How is a colorimeter used to evaluate the color grade of honey? Standardize Quality with Pfund Grading

- What role do high-capacity electronic scales play in honey harvesting? Optimize Commercial Apiary ROI

- How do professional fermentation tanks and packaging systems facilitate the commercialization of honey-derived products?

- What is the primary purpose of liquid nitrogen pre-freezing for drone larvae? Ensure Quality with Rapid Cooling

- Why is it commercially important to select specialized honey machinery? Boost Efficiency with Region-Specific Tools

- What are the key considerations for beekeepers when choosing a honey processing plant? Ensure Quality and Efficiency for Your Apiary

- What are the advantages of integrating advanced honey extraction and processing machinery into industrial beekeeping?

- Why are industrial low-temperature freezers necessary for royal jelly? Lock Bioactivity and Ensure Long-Term Potency