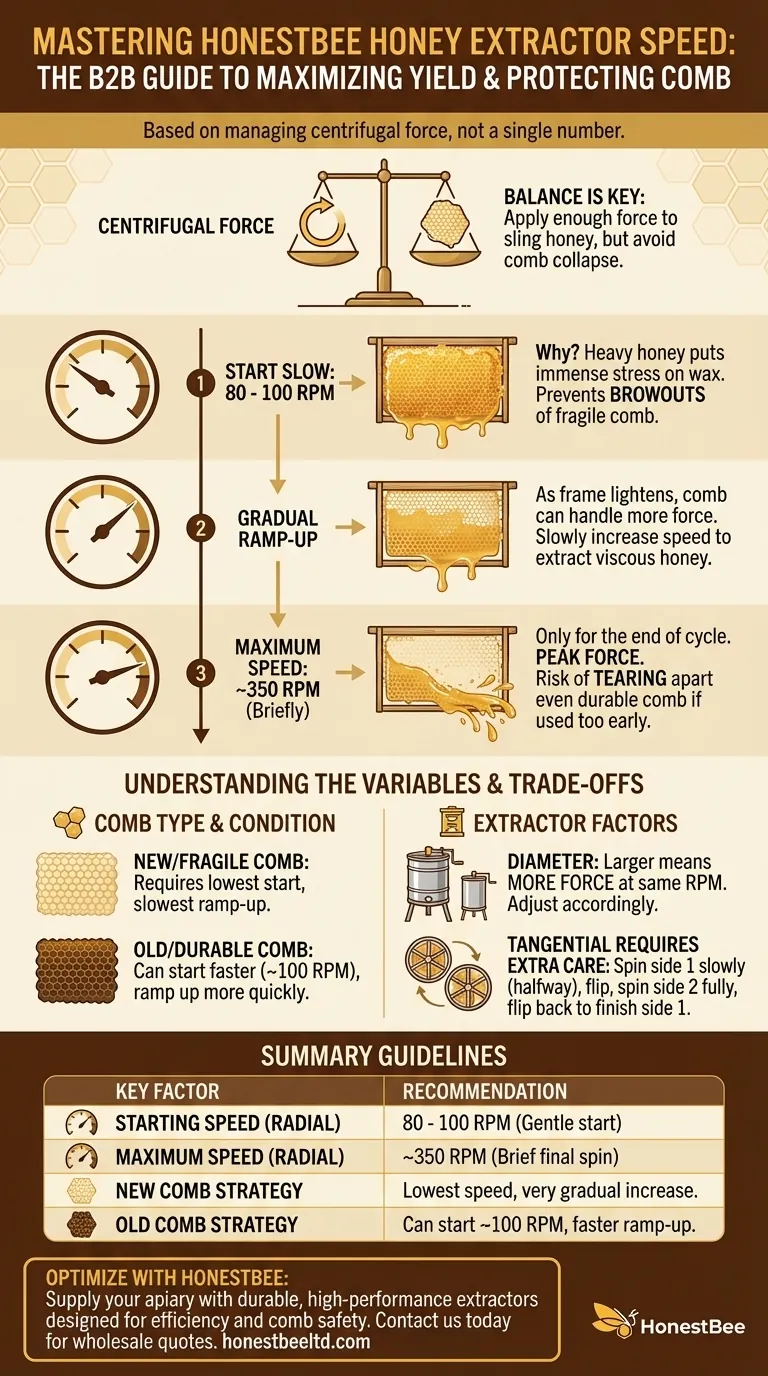

To operate a honey extractor effectively, you must think in terms of a speed range, not a single number. For a common radial extractor, the process starts slow at approximately 80 RPM and gradually increases to a maximum of around 350 RPM. The key is this gradual increase, as starting at full speed will destroy your valuable honeycomb.

The core principle of honey extraction is not about achieving a specific speed, but about managing centrifugal force. You must apply enough force to sling the honey out, but not so much that you cause the delicate wax comb to collapse under its own weight.

The Physics of Safe Honey Extraction

Honey extraction is a delicate balancing act. You are using centrifugal force to overcome the honey's viscosity and its adhesion to the wax cells. Understanding this principle is the key to preserving your comb.

Why You Must Start Slow

A frame full of honey is heavy. When the extractor first starts spinning, the inertia and weight of the honey place immense stress on the wax structure of the comb.

Starting at a low speed, around 80-100 RPM, allows the heaviest portion of the honey to be gently slung out from the cells on both sides of the frame's foundation. A sudden, high-speed start would cause this weight to "blow out" the comb, breaking it from its central foundation.

The Gradual Ramp-Up

As the initial honey is extracted, the frame becomes significantly lighter and the comb structure is no longer under as much stress. This is the point where you can begin to slowly increase the rotational speed.

This gradual increase allows you to extract the remaining, often more viscous, honey that clings to the cell walls without introducing a sudden, destructive force.

The Risk of Maximum Speed

The maximum speed, around 350 RPM for many radial models, should only be used briefly at the end of the cycle. At this speed, the centrifugal force is at its peak.

If you reach this speed too early, or if your comb is particularly fragile (such as newly drawn comb), the force can be enough to tear the wax structure apart, resulting in a "comb collapse."

Understanding the Key Trade-offs

Your decisions while running the extractor directly impact efficiency and equipment longevity. There are no universal settings, only informed compromises.

Speed vs. Comb Safety

The primary trade-off is between the speed of extraction and the safety of your comb. Higher speeds extract honey faster, but dramatically increase the risk of damage.

Newly drawn white comb is extremely fragile and requires a much slower start and a more gentle ramp-up. Older, darker comb, which has been reinforced with pupal cocoons over several brood cycles, is far more durable and can withstand higher forces.

Extractor Type and Size

The numbers provided are a general guide. The actual force applied depends on the extractor's diameter and type.

A larger diameter extractor will generate significantly more force at the same RPM than a smaller one. Therefore, a large commercial extractor might run at a lower RPM than a small hobbyist model to achieve the same result.

A radial extractor spins the frames with the top bar facing outward, slinging honey from both sides at once. A tangential extractor places one side of the comb facing out, requiring you to stop, flip the frames, and repeat the process to extract from the other side. Tangential models require even more care on the first spin to avoid blowouts.

Making the Right Choice for Your Goal

Always observe your equipment. Listen for signs of frames shifting and watch the flow of honey to gauge your progress. Adjust your speed based on what you see and the type of comb you are working with.

- If your primary focus is preserving new, fragile comb: Start at the lowest possible speed (e.g., 80 RPM) and increase the speed in very small, slow increments, never rushing to the maximum.

- If your primary focus is extracting from old, durable comb: You can be more assertive with your speed, starting around 100 RPM and ramping up to the maximum more quickly to save time.

- If you are using a tangential extractor: You must spin the first side very slowly to remove about half the honey, then flip the frames and extract the second side completely before flipping back to finish the first side.

Ultimately, mastering your honey extractor is about developing a feel for the process and prioritizing the long-term health of your comb.

Summary Table:

| Key Factor | Recommended Guideline |

|---|---|

| Starting Speed (Radial Extractor) | 80 - 100 RPM |

| Maximum Speed (Radial Extractor) | ~350 RPM (briefly) |

| New/Fragile Comb | Start at lowest speed; increase very gradually |

| Old/Durable Comb | Can start faster (~100 RPM); ramp up more quickly |

| Extractor Type | Larger diameter = more force at same RPM; Tangential requires extra care |

Optimize Your Honey Extraction Process with HONESTBEE

Mastering the correct speed is crucial for protecting your investment in honeycomb and equipment. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, high-performance extractors and supplies designed for efficiency and comb safety.

Let our expertise and wholesale-focused operations support your business. We provide the reliable equipment you need to maximize yield and minimize comb damage season after season.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and request a quote.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- How do hand-cranked cast iron centrifugal extractors function? Enhance Honey Purity & Hive Efficiency

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors

- What are the technical benefits of using industrial-grade honey extraction equipment? Boost Yields & Quality

- What is the primary function and advantage of a manual honey centrifuge? Boost Efficiency and Preserve Comb Integrity

- What is the machine used to remove honey from the honeycomb? Unlock Efficient Honey Harvesting

- What are the safety tips for using electric honey extractors? Essential Guidelines for Secure Honey Harvesting

- What are the advantages and disadvantages of letting bees clean a honey extractor? Weighing Risks vs. Resource Recovery

- What is the appropriate time to extract honey? Master the Signs of Honey Ripeness for a Perfect Harvest