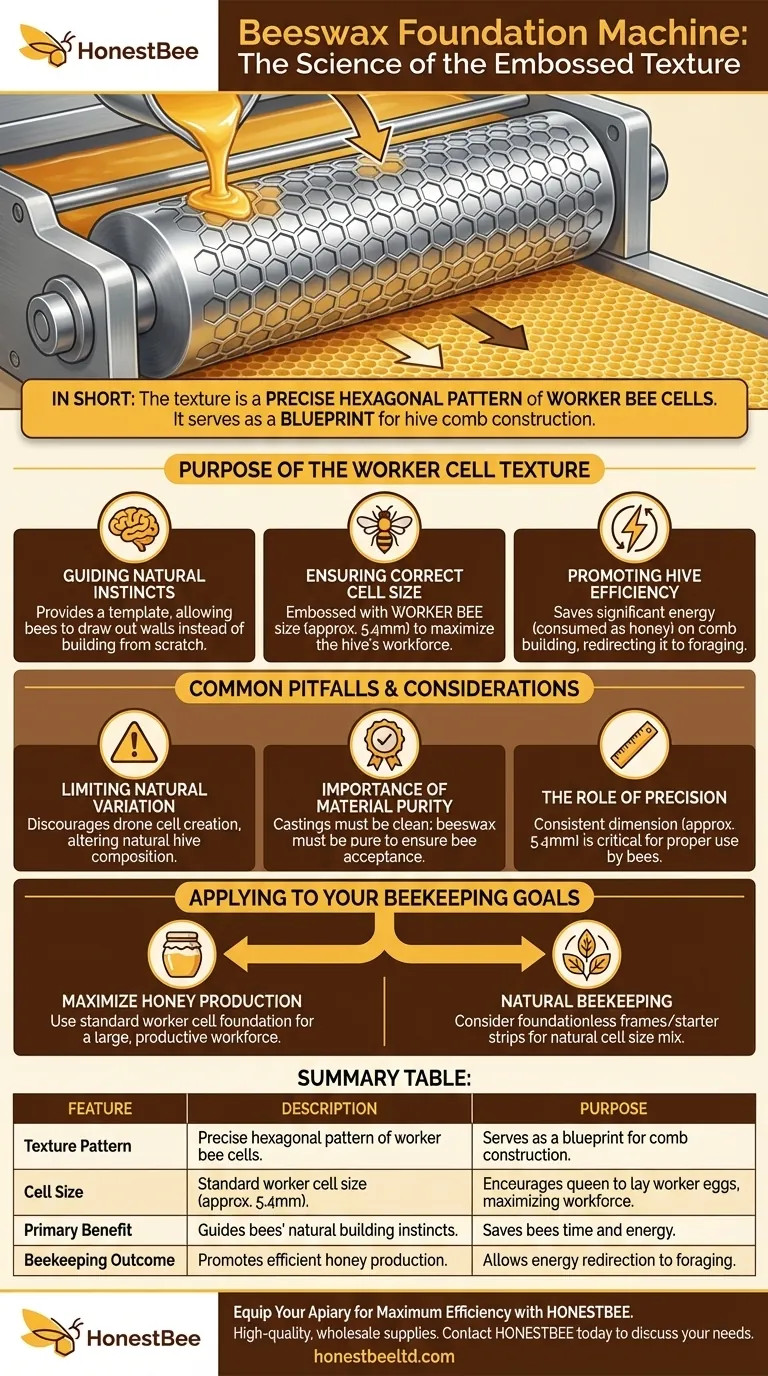

In short, the texture embossed on the aluminium alloy castings is the precise hexagonal pattern of worker bee cells. This pattern serves as a blueprint, or foundation, for the honeybees to build their wax comb upon. The machine presses this specific texture onto sheets of beeswax, which beekeepers then place into their hives.

The core function of this texture is to guide the bees' natural construction instincts. By providing the exact size and shape of a worker cell, the foundation encourages the colony to build the most productive type of comb, saving them significant time and energy.

The Purpose of the Worker Cell Texture

The design of a beeswax foundation machine is not arbitrary; it's engineered to align directly with the biological needs and behaviors of a healthy honeybee colony. The specific texture is the most critical element of this design.

Guiding Natural Instincts

Honeybees have an innate drive to build hexagonal wax cells. The embossed foundation provides a perfect template for them to follow. They draw out the walls of the cells from the provided pattern, rather than having to construct the entire structure from scratch.

Ensuring Correct Cell Size

The foundation is specifically embossed with the cell size for worker bees. This is the most numerous and vital caste in the hive, responsible for foraging, nursing young, and producing honey. By providing this template, the beekeeper encourages the queen to lay worker eggs, maximizing the hive's workforce.

Promoting Hive Efficiency

Building wax comb is an energy-intensive process for bees; they must consume large amounts of honey to produce small amounts of wax. The foundation gives them a massive head start, allowing them to redirect that energy toward other critical tasks like collecting nectar and pollen.

Common Pitfalls and Considerations

While using a foundation with a worker cell pattern is the industry standard for efficiency and productivity, it's essential to understand the context and potential downsides.

Limiting Natural Cell Variation

In a completely natural environment, bees will build a mix of cell sizes, including larger cells for male bees (drones). Using a uniform worker cell foundation heavily discourages the creation of drone cells. While often desirable for maximizing honey production, it does alter the natural composition of the hive.

Importance of Material Purity

The effectiveness of the foundation relies on the bees accepting it. The aluminium alloy castings must be clean and well-maintained to produce a crisp, accurate pattern. Furthermore, the beeswax used to create the foundation sheets must be pure and free from contaminants, which could cause the bees to reject it.

The Role of Precision

The term "exact texture" is key. The dimensions of worker cells are very specific (around 5.4mm is a common standard). The aluminium castings must hold this precise dimension consistently to create a foundation that the bees will readily and properly use.

Applying This to Your Beekeeping Goals

Understanding the purpose of the embossed texture allows you to make more informed decisions for managing your hives.

- If your primary focus is maximizing honey production: Using a standard worker cell foundation is the most effective method for quickly building a large, productive workforce.

- If your primary focus is on natural beekeeping or breeding: You might consider using foundationless frames or starter strips, which allow the bees to build their own comb with a natural mix of cell sizes.

Ultimately, the embossed worker cell pattern is a powerful tool that leverages bee biology to achieve specific beekeeping outcomes.

Summary Table:

| Feature | Description | Purpose |

|---|---|---|

| Texture Pattern | Precise hexagonal pattern of worker bee cells. | Serves as a blueprint for bees to build wax comb. |

| Cell Size | Standard worker cell size (approx. 5.4mm). | Encourages queen to lay worker eggs, maximizing hive workforce. |

| Primary Benefit | Guides bees' natural building instincts. | Saves bees significant time and energy in comb construction. |

| Beekeeping Outcome | Promotes efficient honey production. | Allows bees to redirect energy to foraging and other tasks. |

Equip Your Apiary for Maximum Efficiency with HONESTBEE

For commercial apiaries and beekeeping equipment distributors, the precision of your foundation machine's embossed texture is paramount for hive productivity. HONESTBEE supplies high-quality, durable beekeeping supplies and equipment through wholesale-focused operations, ensuring your foundation machines produce the exact worker cell pattern needed for superior honey yields.

Let us help you optimize your beekeeping operations. Contact HONESTBEE today to discuss your wholesale supply needs and enhance your hive management.

Visual Guide

Related Products

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- What is the role of a Wax Printer or Foundation Mold in improving honeybee hive construction efficiency? Save Bee Energy

- What is the role of a casting mould in the production of beeswax foundations? Essential Guide for Standardized Beekeeping

- What is the function of foundation sheet processing machinery? Boost Honey Yields and Bee Efficiency