For large-scale honey production, the recommended choice is an automatic honey processing machine. This equipment is engineered for high speeds and minimal manual intervention, making it the most efficient solution for operations where processing a high volume of honey quickly and consistently is the primary goal.

The decision to invest in processing equipment goes beyond a single machine. It's about building an integrated system that ensures efficiency, maintains product integrity, and meets safety standards, which are the foundational pillars of any successful large-scale honey operation.

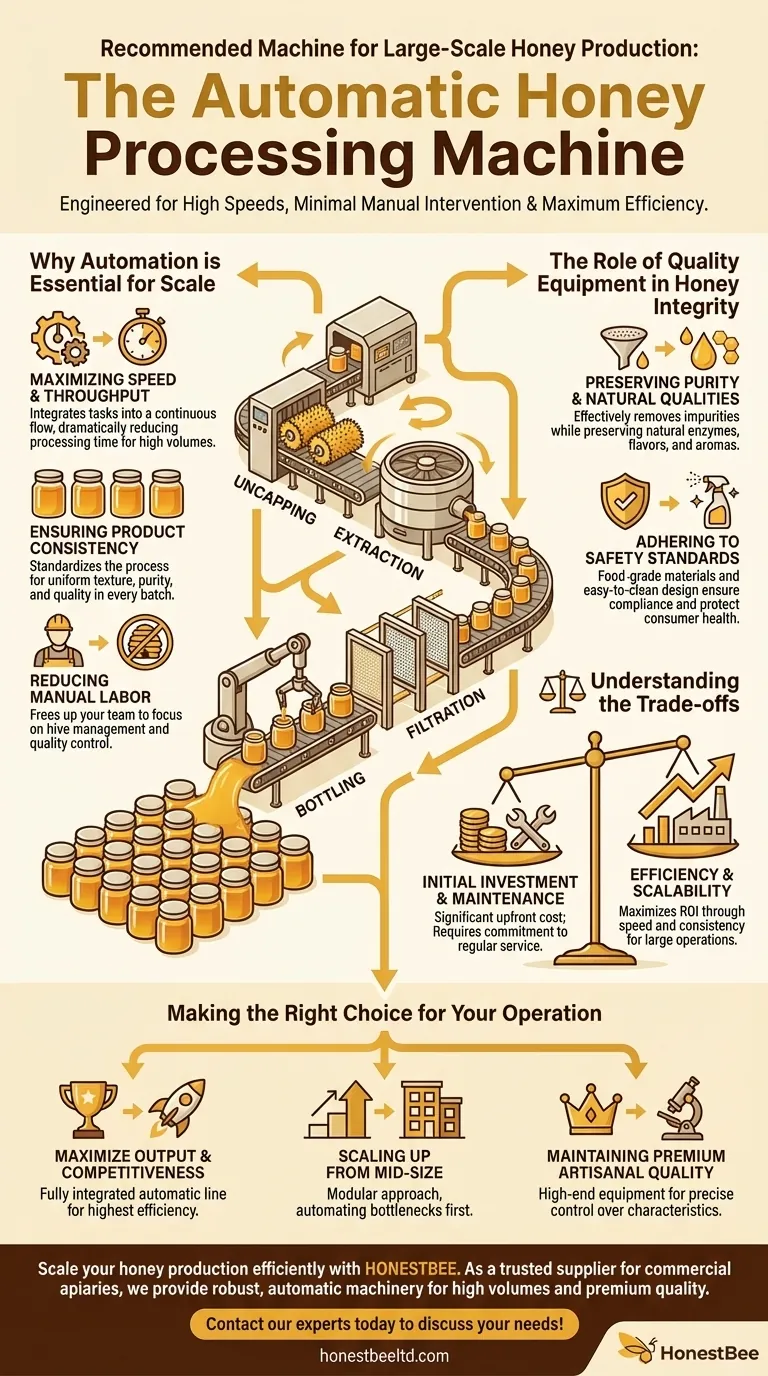

Why Automation is Essential for Scale

Moving from a small-scale or hobbyist setup to commercial production introduces challenges that can only be solved with automation. The core benefits are tied directly to speed, consistency, and labor efficiency.

Maximizing Speed and Throughput

An automatic system integrates tasks like uncapping, extraction, filtration, and bottling into a continuous flow. This dramatically reduces the time it takes to process honey from the comb to the final container, allowing you to handle a much larger volume in a shorter period.

Ensuring Product Consistency

Manual processing can introduce variability between batches. Automation standardizes the process, ensuring that every jar of honey has the same texture, purity, and quality. This consistency is critical for building a reliable brand and earning customer trust.

Reducing Manual Labor

Large-scale honey production involves significant physical labor. Automating the most demanding tasks frees up your team to focus on other critical aspects of the business, such as hive management, quality control, and distribution.

The Role of Quality Equipment in Honey Integrity

The quality of your equipment has a direct impact on the quality of your final product. Investing in superior machinery is not just about efficiency; it is a vital step in preserving the value of your honey.

Preserving Purity and Natural Qualities

High-quality extractors and filtration systems are designed to effectively remove wax, debris, and other impurities. Crucially, they do this while preserving the honey's delicate natural enzymes, flavors, and aromas, which define its premium value.

Adhering to Safety and Sanitation Standards

Commercial honey production is subject to strict food safety regulations. Professional-grade processing equipment is built with food-grade materials and designed for easy cleaning and sanitation, ensuring you can meet and exceed these standards to protect consumer health.

The Foundation: Hives and Tools

Your processing line is the final step in a larger system. The process begins with the right beehives, such as the Langstroth hive, which is highly favored for commercial apiaries due to its flexibility and potential for high honey yields.

Understanding the Trade-offs

While automation is the clear choice for large-scale operations, it is essential to approach this investment with a clear understanding of the associated considerations.

The Initial Investment

The primary trade-off is the significant upfront cost. Automatic honey processing lines represent a substantial capital investment compared to manual or semi-automatic equipment.

Maintenance and Downtime

Advanced machinery requires a commitment to regular maintenance to operate effectively. While reliable equipment minimizes unexpected breakdowns, a plan for routine service is necessary to prevent costly downtime during peak season.

Matching Equipment to Scale

It is crucial to select equipment that matches your current and projected operational scale. Overinvesting in capacity you will not use is inefficient, while underinvesting will create bottlenecks as your operation grows.

Making the Right Choice for Your Operation

Your decision should be guided by your specific business goals.

- If your primary focus is maximizing output and market competitiveness: A fully integrated, automatic processing line is the necessary investment to achieve the highest levels of efficiency.

- If your primary focus is scaling up from a mid-size operation: Consider a modular approach, investing first in automated equipment for the most significant bottlenecks, such as extraction or bottling.

- If your primary focus is maintaining premium, artisanal quality at scale: Invest in high-end equipment that offers precise control over factors like temperature and filtration to preserve the unique characteristics of your honey.

Investing in the right processing system is a direct investment in the quality, consistency, and long-term viability of your honey business.

Summary Table:

| Key Factor | Benefit of Automation |

|---|---|

| Throughput | Maximizes speed and volume with continuous processing. |

| Consistency | Ensures uniform quality in every batch for brand reliability. |

| Labor | Reduces manual effort, allowing focus on hive management. |

| Product Integrity | Preserves honey's natural enzymes and flavor during processing. |

| Compliance | Meets food safety standards with easy-to-clean, food-grade materials. |

Scale your honey production efficiently with HONESTBEE.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide the robust, automatic processing machinery you need to handle high volumes while maintaining premium quality. Our wholesale-focused operations ensure you get reliable equipment that maximizes your ROI.

Ready to build your high-capacity honey processing line? Contact our experts today to discuss your specific needs and get a tailored solution.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What are the advantages of using automated stainless steel honey extraction equipment? Boost Your Yield and Purity

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries

- What are the typical features and working principles of a bucket honey press? Optimize Your Honey Extraction

- How does pressed honey compare to extracted or crush-and-strain? Unlock the Full Flavor of the Hive

- What are the key features of the stainless steel honey press? Maximize Yield & Guarantee Purity