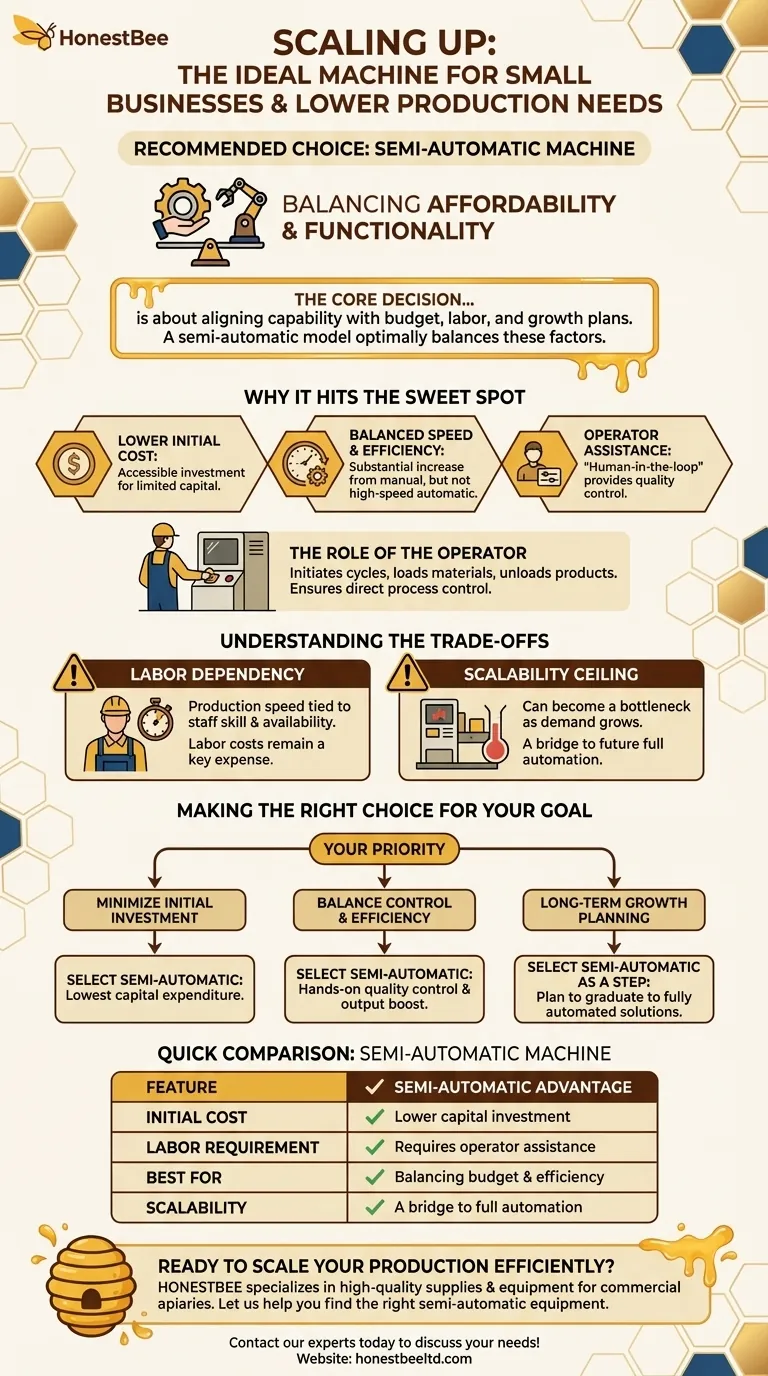

For a smaller business or one with lower production needs, the recommended choice is a semi-automatic machine. This type of equipment provides a critical balance between affordability and functionality, offering a significant step up from manual processes without the substantial capital investment required for fully automated systems.

The core decision for a small business isn't just about the machine's capability, but how that capability aligns with your immediate budget, labor availability, and future growth plans. A semi-automatic model is the most common answer because it optimally balances these competing factors.

Why a Semi-Automatic Model Hits the Sweet Spot

When evaluating equipment, the primary factors are cost, speed, and labor. A semi-automatic machine occupies the middle ground, making it a pragmatic entry point for businesses scaling their operations.

The Role of the Operator

A key distinction of semi-automatic equipment is the requirement for manual assistance. An operator is typically needed to initiate a cycle, load materials, or unload the finished product.

This "human-in-the-loop" approach provides direct control over the process, which can be beneficial for quality assurance in early production stages.

Balancing Cost and Output

The initial purchase price of a semi-automatic machine is significantly lower than that of a fully automatic one. This makes it a much more accessible investment for businesses with limited capital.

While it won't match the high-speed output of a fully automated system, it delivers a substantial increase in efficiency and consistency compared to purely manual labor.

Understanding the Trade-offs

Choosing a semi-automatic machine is a strategic decision with clear benefits, but it's crucial to understand the inherent limitations.

Labor Dependency

The most significant trade-off is the reliance on an operator. Your production speed is directly tied to the skill and availability of your staff.

This can introduce variability into your output and means that labor costs remain a key operational expense.

Scalability Ceiling

As your business grows and demand increases, a semi-automatic machine can become a bottleneck. At a certain point, the cost of adding more labor to meet production targets will make upgrading to a fully automatic system more financially viable.

This is not a flaw, but a natural stage in the equipment's lifecycle. It serves as a bridge to higher levels of automation.

Making the Right Choice for Your Goal

Selecting the right machine depends entirely on your business priorities.

- If your primary focus is minimizing initial investment: A semi-automatic model is the clear choice, offering the lowest capital expenditure for mechanized production.

- If your primary focus is balancing control and efficiency: The hands-on nature of a semi-automatic machine provides excellent quality control while still boosting output.

- If your primary focus is long-term growth planning: View the semi-automatic machine as your first step, with the understanding that you will eventually graduate to a fully automated solution as your volume dictates.

Ultimately, a semi-automatic machine empowers a small business to professionalize its production without overextending its financial resources.

Summary Table:

| Feature | Semi-Automatic Machine |

|---|---|

| Initial Cost | Lower capital investment |

| Labor Requirement | Requires operator assistance |

| Best For | Balancing budget & efficiency |

| Scalability | A bridge to full automation |

Ready to scale your production efficiently? At HONESTBEE, we specialize in supplying high-quality beekeeping supplies and equipment to commercial apiaries and distributors. Let us help you find the right semi-automatic equipment to balance your budget and boost your output. Contact our experts today to discuss your needs!

Visual Guide

Related Products

- Semi Automatic Electric Bottle Capping Machine

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- What role do specialized field trap nests play in environmental education? Enhancing Learning through stingless bees

- How do beehive environment monitoring systems predict foraging flights? Unlock Data-Driven Apiary Insights

- Why are professional measurement tools required for assessing honeybee spring build-up? Boost Colony Growth Accuracy

- How does colony size affect hive temperature and moisture? Master Hive Climate Control for Healthier Bees

- Importance of Professional Beekeeping Consumables in AES: Optimize Health Management for Sustainable Agri-Success

- How can a beekeeper prevent bees from returning to their original hive? Proven Strategies for Same-Apiary Splits

- Why are traditional log hives essential for wild honeybee colonies? Expert Guide to Natural Forest Beekeeping

- What is the significance of specialized beekeeping equipment and hives? Powering Ecological & Agricultural Success