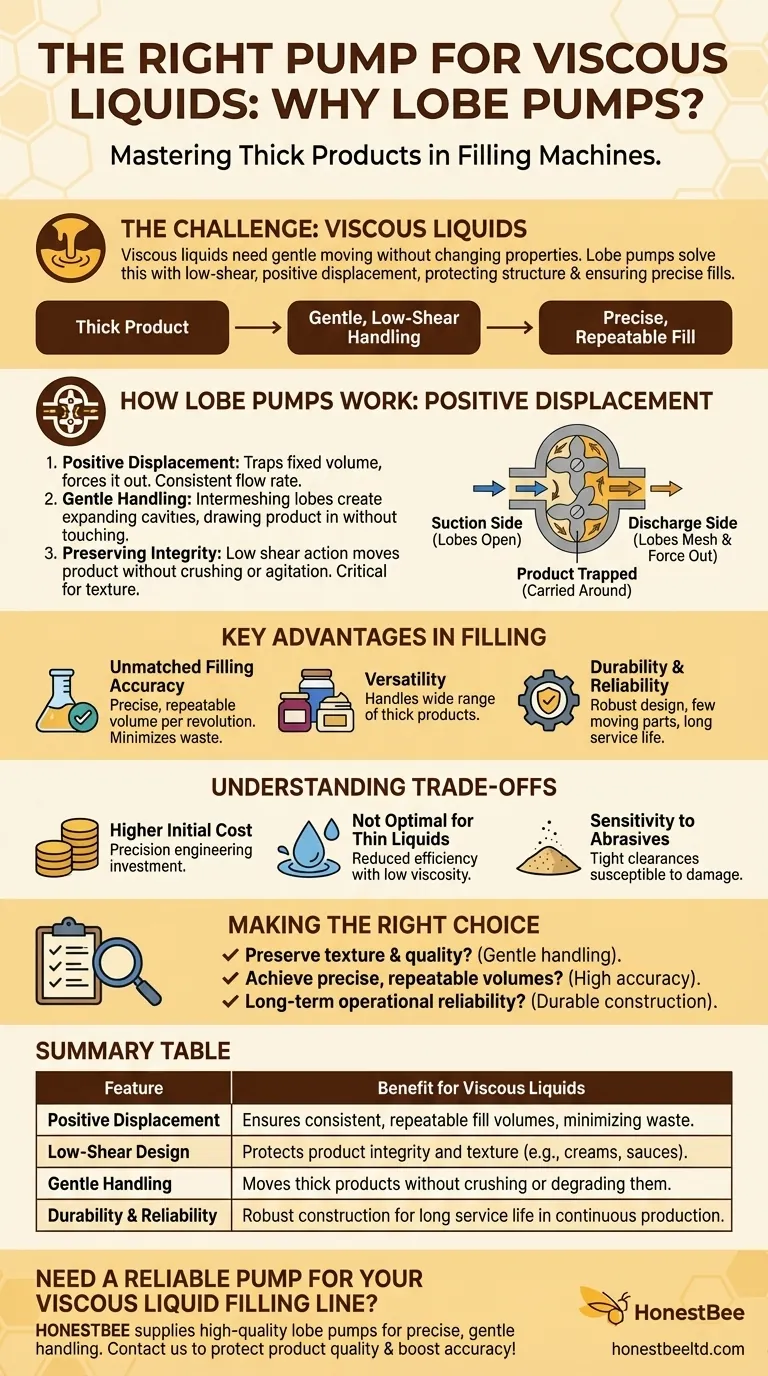

For filling machines handling viscous liquids, the most common and effective choice is a lobe pump. This type of positive displacement pump is specifically engineered to move thicker products gently and accurately, without compromising the product's integrity or texture during the filling process.

The core challenge with viscous liquids is moving them without changing their fundamental properties. Lobe pumps solve this by using a low-shear, positive displacement mechanism that protects product structure while ensuring each fill is precise and repeatable.

How Lobe Pumps Master Viscous Liquids

The effectiveness of a lobe pump comes from its fundamental design as a positive displacement pump. This mechanism is uniquely suited for the challenges that thick, shear-sensitive products present.

The Principle of Positive Displacement

A positive displacement pump works by trapping a fixed amount of fluid and then forcing (displacing) that trapped volume into the discharge pipe. This ensures a consistent and measurable flow rate directly proportional to the pump's speed.

This method is fundamentally different from a centrifugal pump, which uses kinetic energy and high speed to move fluid. The high-shear action of a centrifugal pump can degrade or alter the viscosity of thick products.

Gentle Handling with Intermeshing Lobes

The "heart" of the pump consists of two or more rotating lobes that intermesh without touching. As they rotate, they create expanding cavities on the suction side, drawing the product into the pump.

The product is then carried around the interior of the pump casing in the pockets between the lobes and the casing wall. Finally, as the lobes mesh on the discharge side, the cavity size shrinks, forcing the product out in a smooth, continuous stream.

Preserving Product Integrity

The entire process is characterized by low shear. Because the lobes do not touch and the clearances are precise, the pump moves the product without crushing, agitating, or breaking it down. This is critical for cosmetics, food products, and pharmaceuticals where texture and consistency are paramount.

Key Advantages in Filling Operations

Selecting a lobe pump for a viscous liquid filling line provides several distinct operational benefits that directly impact product quality and production efficiency.

Unmatched Filling Accuracy

The positive displacement nature of a lobe pump means that for every revolution, a precise, repeatable volume of product is dispensed. This volumetric consistency is the foundation of accurate and reliable filling operations, minimizing product waste and ensuring label-weight compliance.

Versatility Across Viscosities

Lobe pumps excel with a wide range of thick products, from pastes and gels to creams and sauces. Their ability to handle these substances without damage makes them a versatile solution for many industries.

Durability and Reliability

As noted, these pumps are built to be robust and durable. Their simple design with few moving parts and non-contacting lobes leads to less wear and tear, ensuring a long service life even in demanding, continuous production environments.

Understanding the Trade-offs

While ideal for viscous applications, lobe pumps are not a universal solution. Understanding their limitations is key to making an informed decision.

Higher Initial Investment

Lobe pumps are precision-engineered devices and typically carry a higher initial cost compared to simpler pump designs like centrifugal pumps. This cost, however, is often justified by their performance and longevity.

Not Optimal for Thin Liquids

These pumps are less efficient when handling very thin, water-like liquids. Low-viscosity fluids can "slip" back through the tight clearances between the lobes and casing, reducing volumetric accuracy.

Sensitivity to Abrasives

While robust, the precise clearances within a lobe pump can be susceptible to damage from hard, abrasive particles in the fluid. If your product contains abrasives, a different pump type or specific material selection may be necessary.

Making the Right Choice for Your Product

Your specific goal will determine if a lobe pump is the correct tool for your filling application.

- If your primary focus is preserving product texture and quality: A lobe pump is the definitive choice for its gentle, low-shear handling of viscous and sensitive liquids.

- If your primary focus is achieving precise, repeatable fill volumes: The positive displacement mechanism of a lobe pump provides the high degree of accuracy required for consistent packaging.

- If your primary focus is long-term operational reliability: The durable construction and simple design of a lobe pump ensure it will be a dependable component of your production line.

Ultimately, selecting a lobe pump is an investment in protecting your product's integrity and guaranteeing the accuracy of your filling process.

Summary Table:

| Feature | Benefit for Viscous Liquids |

|---|---|

| Positive Displacement | Ensures consistent, repeatable fill volumes, minimizing waste. |

| Low-Shear Design | Protects product integrity and texture (e.g., creams, sauces). |

| Gentle Handling | Moves thick products without crushing or degrading them. |

| Durability & Reliability | Robust construction for long service life in continuous production. |

Need a reliable pump for your viscous liquid filling line?

HONESTBEE supplies high-quality, durable lobe pumps and beekeeping equipment to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the precise, gentle handling equipment your production demands.

Contact HONESTBEE today to discuss how our lobe pumps can protect your product quality and boost your filling accuracy!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What is the role of a portable electric vacuum pump in stingless bee honey collection for palynological analysis?

- What is the function of an industrial-grade micro diaphragm pump in beehive gas measurement? Ensure Data Precision

- Why is the pre-sterilization of honey suction equipment critical for Heterotrigona itama? Prevent Rapid Spoilage

- What are the capacity options for stainless steel screw honey pumps? Choose the Right Flow for Your Apiary

- What types of pumps are available for honey processing? Choose the Right Pump to Protect Honey Quality

- What voltage options are available for stainless steel screw honey pumps? Choose the Right Power for Your Scale

- What is the primary role of the Honey Suction Pump? Boost Efficiency in Stingless Bee Honey Harvesting

- Where are stainless steel screw honey pumps commonly used? In Commercial Honey Processing & Quality-Focused Operations