At its core, a honey packaging line consists of three main types of machines: a filling machine to dispense the honey, a capping machine to seal the container, and a labeling machine to apply the branding. The most critical choice is the filling technology, which is typically either a piston-based system for precision or a gravity-fed system for simplicity.

Choosing the right equipment is not about a single machine, but about building an integrated system. The ideal setup depends entirely on your production scale, the viscosity of your honey, and the type of container you plan to sell.

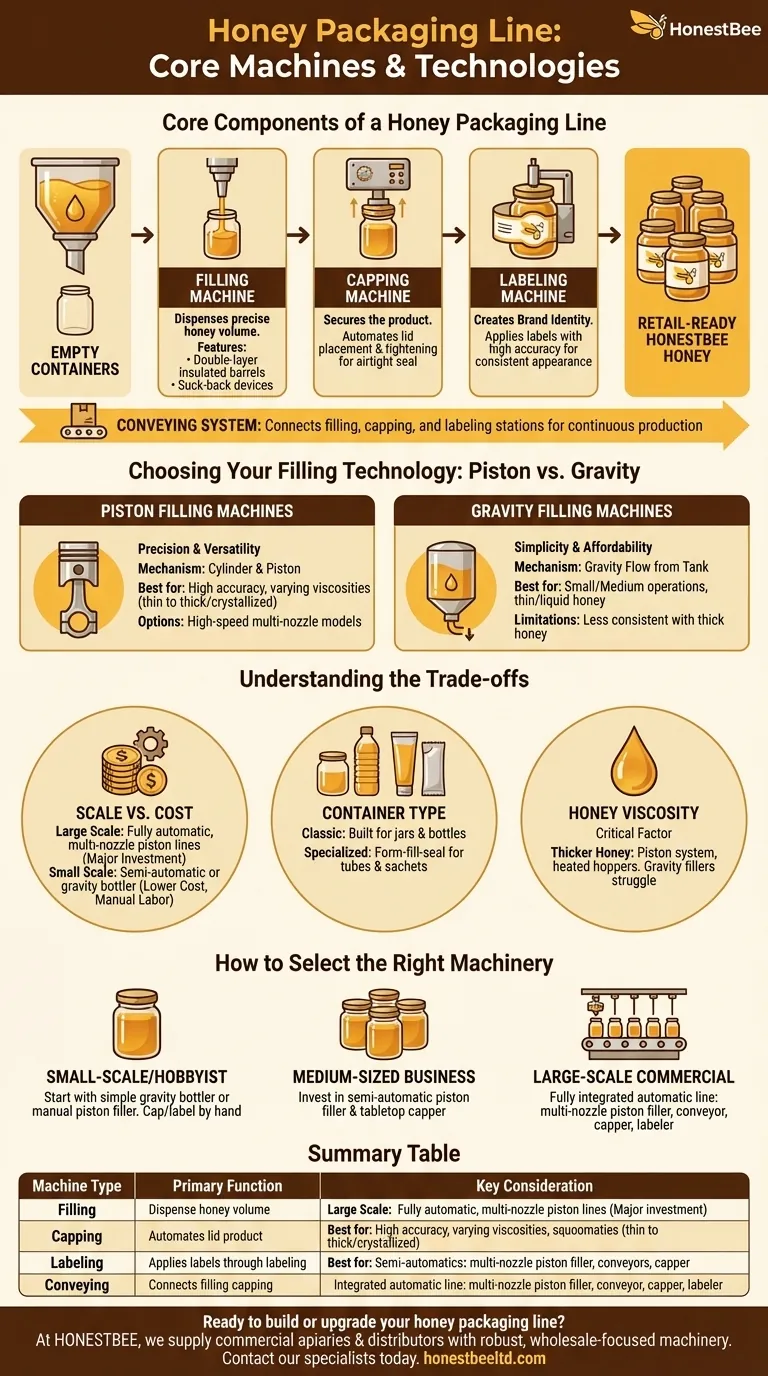

The Core Components of a Honey Packaging Line

A complete, automated line moves containers seamlessly from empty to retail-ready. Each machine performs a distinct and essential function in this process.

The Filling Machine: The Heart of the Operation

The filling machine is responsible for dispensing a precise, repeatable volume of honey into each jar, bottle, or container.

Modern honey fillers often include specialized features like double-layer insulated barrels to maintain a consistent temperature and viscosity. They also incorporate suck-back devices at the nozzle to ensure a clean cutoff and prevent drips.

The Capping Machine: Securing the Product

Once filled, the container moves to a capping machine. This device automatically places and tightens the lid, ensuring a secure, airtight seal to preserve the honey's freshness and prevent leaks.

The Labeling Machine: Creating the Brand Identity

The labeling machine applies your branded labels to the container. These machines are designed for high accuracy, ensuring every product has a consistent, professional appearance on the shelf.

The Conveying System: The Connecting Tissue

A conveying system is the automated belt that transports containers from the filling station to the capper and then to the labeler. This is what transforms a series of separate tasks into an efficient, continuous production line.

Choosing Your Filling Technology: Piston vs. Gravity

The filling machine is the most significant investment and has the biggest impact on your line's efficiency. The two dominant technologies serve different needs.

Piston Filling Machines: Precision and Versatility

A piston filler uses a cylinder and piston mechanism to pull in a specific volume of honey and then push it out into the container.

This method offers extremely high accuracy and can easily handle products with varying viscosities, from thin, liquid honey to thicker, partially crystallized honey. High-speed models can be equipped with multiple nozzles to fill several bottles at once, drastically increasing output.

Gravity Filling Machines: Simplicity and Affordability

A gravity filler holds the honey in a tank above the fill heads. When a valve opens, gravity causes the honey to flow down into the container below.

These machines are mechanically simpler and generally more affordable, making them a popular choice for small to medium-sized operations. However, their performance can be less consistent with thicker, more viscous honey.

Understanding the Trade-offs

Selecting the right machinery involves balancing cost, speed, and the physical properties of your product and packaging.

Scale vs. Cost

Fully automatic, multi-nozzle piston lines offer incredible speed but represent a major capital investment. They are best suited for large commercial producers.

For smaller businesses, a semi-automatic single-piston filler or a simple gravity bottler offers a much lower entry cost, though at the expense of manual labor and slower production speeds.

Container Type Dictates Machinery

The classic honey packaging line is built for glass jars or plastic bottles. If you plan to use other formats, you will need entirely different equipment.

Packaging honey in squeezable tubes or single-serving sachet bags, for example, requires a specialized "form-fill-seal" machine that creates the package, fills it, and seals it in one continuous motion.

Honey Viscosity Matters

The thickness of your honey is a critical factor. Thicker honey flows slowly and may require fillers with heated hoppers or the superior force of a piston system. A gravity filler will struggle or fail entirely with highly viscous honey.

How to Select the Right Machinery

Your choice should directly align with your business goals and operational scale.

- If your primary focus is a small-scale or hobbyist operation: Start with a simple gravity bottler or a manual single-piston filler. You can cap and label by hand to minimize your initial investment.

- If your primary focus is growing into a medium-sized business: Invest in a semi-automatic piston filler and a separate tabletop capping machine to significantly boost your speed and consistency.

- If your primary focus is large-scale commercial production: A fully integrated, automatic line with a multi-nozzle piston filler, conveyor system, automatic capper, and labeler is necessary to achieve high throughput and minimize labor costs.

Understanding the function of each machine empowers you to build a packaging line that grows with your ambition.

Summary Table:

| Machine Type | Primary Function | Key Consideration |

|---|---|---|

| Filling Machine | Dispenses precise honey volume | Piston for accuracy, Gravity for simplicity |

| Capping Machine | Applies and tightens lids | Ensures airtight seal for freshness |

| Labeling Machine | Applies branding labels | Provides consistent, professional appearance |

| Conveying System | Transports containers between stations | Creates a continuous, automated line |

Ready to build or upgrade your honey packaging line?

At HONESTBEE, we supply commercial apiaries and equipment distributors with the robust, wholesale-focused machinery needed for efficient honey packaging. Whether you're scaling up to a high-speed piston filler or need a reliable gravity system, our expertise ensures you get the right equipment for your specific honey viscosity and production goals.

Contact our packaging specialists today to discuss your requirements and receive a tailored solution quote.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- How does on-site honey bottling equipment benefit beekeeping? Maximize Profit Margins & Brand Control

- What are the advantages of using automated honey-filling machines? Boost Precision and Scale Your Commercial Apiary

- How does a piston filling machine work and why is it suitable for honey? Master High-Viscosity Packaging

- How do high-precision honey filling machines maintain product quality? Ensure Stability in Every Retail Bottle

- What is the principle behind gravity filling machines for honey? A Simple, Cost-Effective Solution for Liquid Honey

- Why is industrial-grade honey filling equipment essential? Secure Global Trade with Precise Automation

- How does high-efficiency honey filling machinery contribute to commercialization? Scaling Your Honey Brand Effectively

- How can Arrhenius model parameters improve honey filling? Optimize Precision in Industrial Honey Machinery