In short, sachet filling and packing machines are designed to handle a wide variety of liquid, paste, and high-density products. They are commonly used for single-serving or sample-sized packaging of items ranging from food products like ketchup, honey, and fruit jam to personal care items like shampoo, hand sanitizer, and facial creams.

The key determining factor isn't the specific product itself, but its physical state. These machines are engineered to manage different levels of viscosity, from thin liquids to thick pastes and spreads.

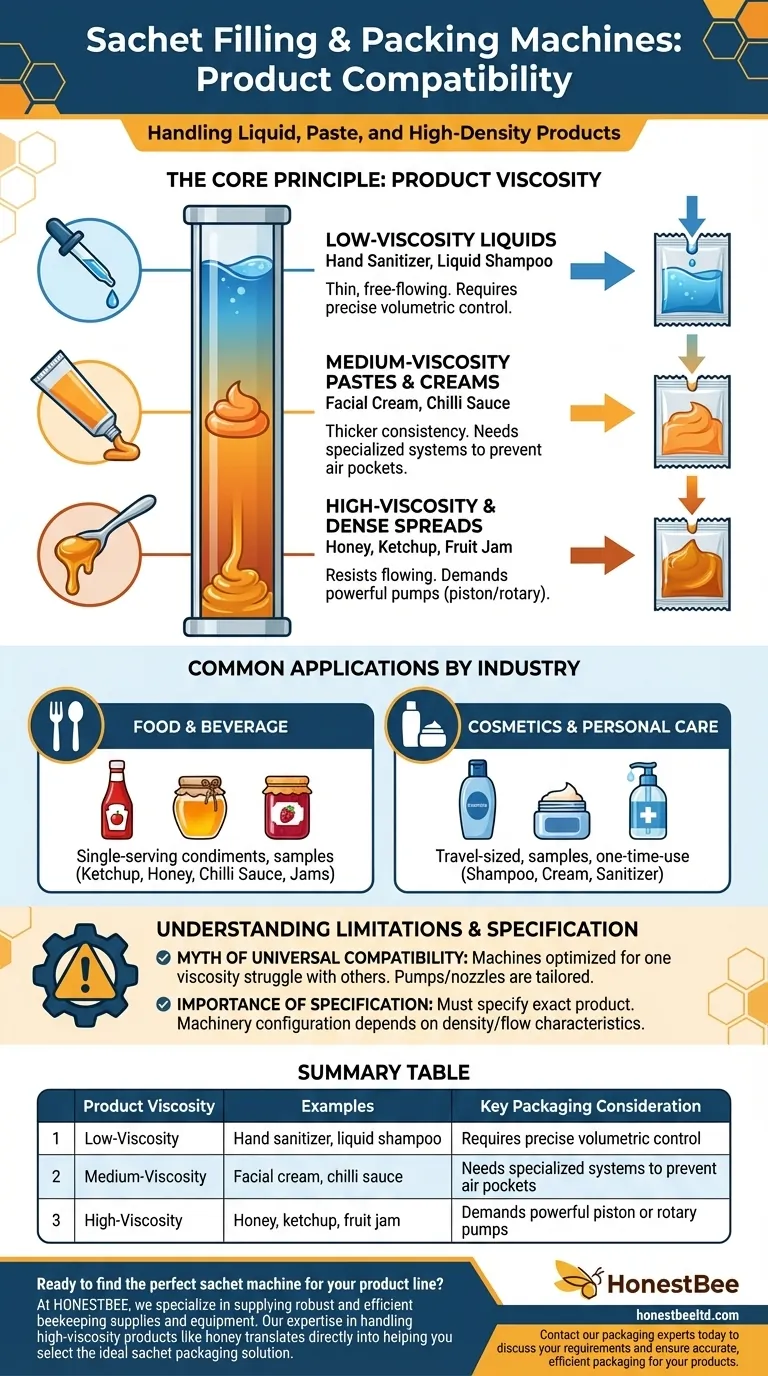

The Core Principle: Product Viscosity and Consistency

The versatility of a sachet filling machine comes from its ability to handle products with different physical properties. The suitability of a product for this type of packaging is almost entirely dependent on its flow characteristics.

Low-Viscosity Liquids

These are thin, free-flowing products that are easily pumped through the machine's filling system.

Examples include hand sanitizer and liquid hair shampoo, which require precise volumetric control to prevent over- or under-filling the sachet.

Medium-Viscosity Pastes and Creams

These products are thicker and require more specialized systems to ensure they are dosed accurately without creating air pockets.

Facial creams and many types of chilli sauce fall into this category, demanding a filling mechanism that can handle their consistency.

High-Viscosity and Dense Spreads

These are the thickest products, which resist flowing and require powerful pumping mechanisms.

Products like honey, marmalade, fruit jam, and ketchup are examples of high-density spreads that need robust machinery to handle their thick texture.

Common Applications by Industry

While the product's physical state is the technical determinant, these machines see widespread use across several key industries. This demonstrates their adaptability to different market needs and packaging standards.

Food and Beverage

This is a primary market for sachet packaging, focusing on single-serving condiments and samples.

Common applications include ketchup, honey, chilli sauce, and various jams.

Cosmetics and Personal Care

Sachets are ideal for travel-sized products, samples, and one-time-use treatments in this sector.

Typical products include hair shampoo, facial cream, and hand sanitizer.

Pharmaceutical and Chemical

Though not detailed in the product examples, sachet machines are widely applied in the pharmaceutical industry for gels and creams, as well as in the chemical sector for specific formulations.

Understanding the Limitations

While highly versatile, these machines are not a "one size fits all" solution. The configuration required for one product type may not be suitable for another without adjustment.

The Myth of Universal Compatibility

A machine optimized for a thin liquid like hand sanitizer will likely struggle with a thick paste like fruit jam.

The pump, nozzles, and filling mechanism are often tailored to a specific range of viscosity.

The Importance of Machine Specification

When sourcing a machine, it is critical to specify the exact products you intend to pack.

This ensures the machinery is equipped with the correct components to handle your product's specific density and flow characteristics accurately and efficiently.

How to Apply This to Your Product

Your product's physical properties will determine the type of sachet machine you need.

- If your primary focus is on thin liquids: Your priority should be a machine with a highly accurate volumetric or gravity-fed filling system to ensure consistent dosing.

- If your primary focus is on thick pastes or creams: You must select a machine with a powerful piston or rotary pump designed to handle high-viscosity materials without failure.

- If your primary focus is on versatility for multiple products: Look for a semi-automatic or modular system that allows for interchangeable pumps and nozzles to adapt to different product types.

Ultimately, matching the machine's technical capabilities to your product's specific consistency is the key to successful sachet packaging.

Summary Table:

| Product Viscosity | Examples | Key Packaging Consideration |

|---|---|---|

| Low-Viscosity Liquids | Hand sanitizer, liquid shampoo | Requires precise volumetric control |

| Medium-Viscosity Pastes | Facial cream, chilli sauce | Needs specialized systems to prevent air pockets |

| High-Viscosity Spreads | Honey, ketchup, fruit jam | Demands powerful piston or rotary pumps |

Ready to find the perfect sachet machine for your product line?

At HONESTBEE, we specialize in supplying robust and efficient beekeeping supplies and equipment to commercial apiaries and distributors. Our expertise in handling high-viscosity products like honey translates directly into helping you select the ideal sachet packaging solution for your specific needs, whether you pack liquids, pastes, or dense spreads.

Contact our packaging experts today to discuss your requirements and ensure accurate, efficient packaging for your products.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- In what ways do industrial honey filling and packaging lines facilitate trade? Scaling Exports with Precision

- Why is the automated honey filling machine considered a core component? Boost Your Commercial Honey Processing Efficiency

- What are the advantages of using high-precision honey-filling machines for Tetragonula iridipennis honey?

- What is the purpose of a volumetric filling machine? Achieve Precise, Repeatable Product Dosing

- What role do high-precision filtering and filling machines play in the post-harvest treatment of stingless bee honey?

- What steps should be taken to find a reliable manufacturer for a honey stick machine? Expert Sourcing Guide

- What is a fully-automatic honey filler? Streamline Your Production with High-Precision Automation

- What is the importance of honey filling machines? Scale Your Production and Ensure Product Integrity