At their core, semi-automatic filling machines are designed for versatility. They are engineered to handle a wide spectrum of products, ranging from thin liquids to thick pastes and even high-density materials. This adaptability makes them a cornerstone for businesses that require precision without the investment of a fully automated system.

The key isn't just the product category, but its physical properties. Semi-automatic fillers excel with products of varying viscosities, offering a cost-effective bridge between manual labor and full automation for businesses needing both precision and flexibility.

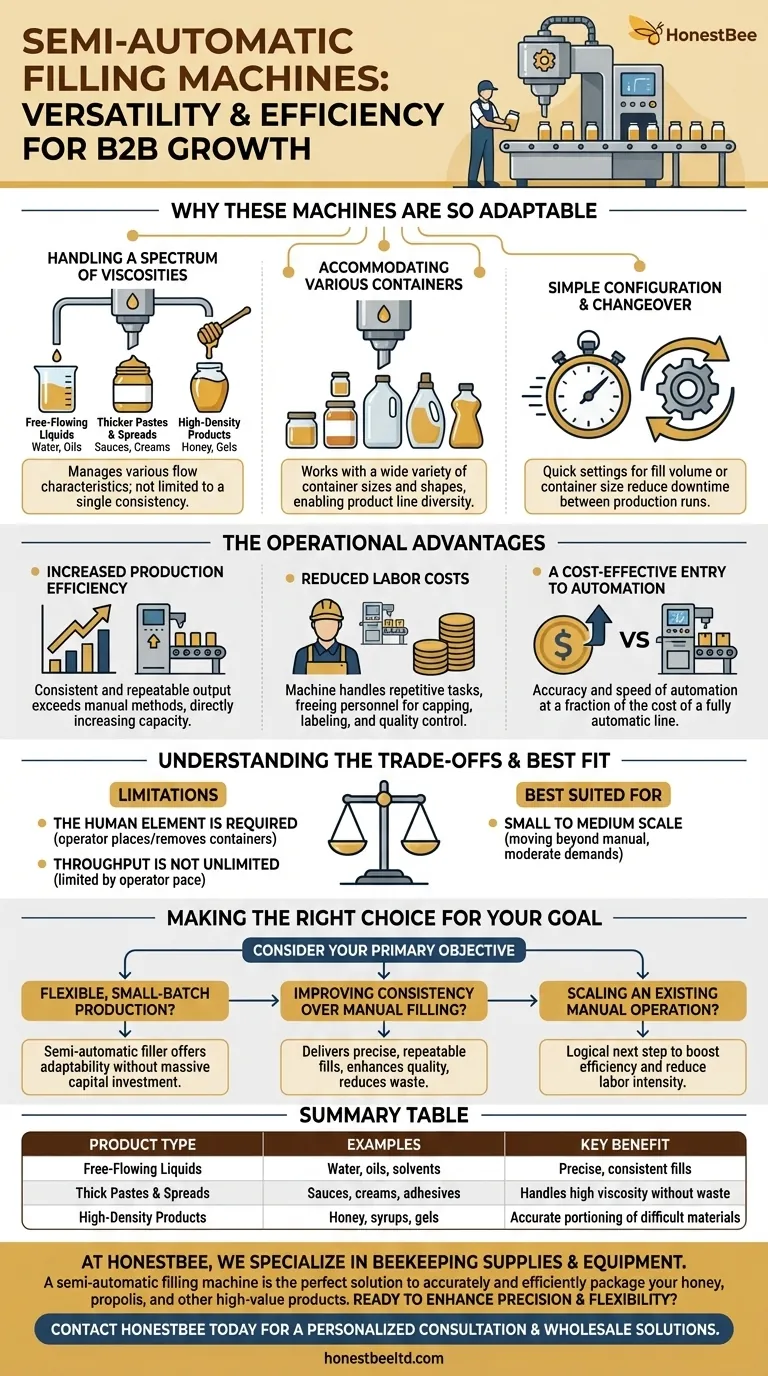

Why These Machines Are So Adaptable

The value of a semi-automatic filler lies in its ability to be easily reconfigured. This design philosophy allows it to serve many different production needs within a single piece of equipment.

Handling a Spectrum of Viscosities

The primary strength of these machines is their capacity to manage products with different flow characteristics. They are not limited to a single consistency.

This includes free-flowing liquids, thicker pastes and spreads, and high-density products like honey that are difficult to portion accurately by hand.

Accommodating Various Containers

A product is only as good as its packaging. These fillers are designed to work with a wide variety of container sizes and shapes.

This means you can switch from filling a small jar to a larger bottle with minimal downtime, allowing for greater product line diversity.

Simple Configuration and Changeover

The "semi-automatic" nature means the system is built for straightforward adjustments. An operator can typically change settings for fill volume or container size quickly.

This reduces downtime between production runs of different products, making it ideal for smaller batches or businesses with diverse offerings.

The Operational Advantages of Semi-Automatic Filling

Beyond product compatibility, these machines introduce significant operational benefits, directly impacting efficiency and cost.

Increased Production Efficiency

By automating the most critical step—the fill—these machines provide a consistent and repeatable output that far exceeds manual methods. This directly increases your production capacity.

Reduced Labor Costs

While an operator is still required, the machine handles the repetitive and precise task of filling. This frees up personnel for other valuable tasks like capping, labeling, and quality control.

A Cost-Effective Entry to Automation

For many businesses, a fully automatic line is a prohibitive expense. A semi-automatic machine provides many of the benefits of automation, such as accuracy and speed, at a fraction of the cost.

Understanding the Trade-offs

As a technical advisor, I must be clear that "versatile" does not mean "perfect for every scenario." Understanding the limitations is key to making a sound investment.

The Human Element is Required

The primary distinction of a semi-automatic system is the need for an operator. This person is responsible for placing containers, initiating the fill cycle, and removing the filled container.

Throughput is Not Unlimited

These machines are a significant step up from manual filling but cannot match the high speeds of a fully integrated, fully automatic production line. Their output is limited by the pace of the operator.

Best Suited for Small to Medium Scale

This technology is the ideal solution for businesses moving beyond manual processes or those with moderate production demands. Companies with extremely high volume needs will eventually need to look at full automation.

Making the Right Choice for Your Goal

To determine if this is the correct path for your operation, consider your primary objective.

- If your primary focus is flexible, small-batch production: A semi-automatic filler offers the adaptability to handle various products and containers without a massive capital investment.

- If your primary focus is improving consistency over manual filling: These machines deliver precise, repeatable fills that enhance product quality and significantly reduce costly waste.

- If your primary focus is scaling an existing manual operation: This is the logical next step to boost efficiency and reduce labor intensity before committing to a fully automated line.

Ultimately, a semi-automatic filler empowers your production line with the precise control and adaptability needed to grow and diversify.

Summary Table:

| Product Type | Examples | Key Benefit |

|---|---|---|

| Free-Flowing Liquids | Water, oils, solvents | Precise, consistent fills |

| Thick Pastes & Spreads | Sauces, creams, adhesives | Handles high viscosity without waste |

| High-Density Products | Honey, syrups, gels | Accurate portioning of difficult materials |

Ready to enhance your production line's precision and flexibility?

At HONESTBEE, we specialize in supplying durable, high-performance beekeeping supplies and equipment to commercial apiaries and distributors. A semi-automatic filling machine is the perfect solution to accurately and efficiently package your honey, propolis, and other high-value products, reducing waste and labor costs.

Let our experts help you find the right equipment to scale your operation. Contact HONESTBEE today for a personalized consultation and discover how our wholesale-focused solutions can drive your business forward.

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What is the significance of professional honey filling and packaging equipment? Unlocking High-End Retail Success

- How do industrial honey-filling machines solve the technical challenges? Mastering Viscosity & Precision

- How does professional honey filling equipment ensure product quality? Secure Your Organic Integrity with Automation

- How do honey filling and processing machines aid native bee product conservation? Boost Value with HONESTBEE Technology

- What processing challenges do honey filling machines address? Optimize Your Commercial Honey Production

- Why are fully automatic honey filling and packaging lines essential? Boost Your Honey's Market Value and Quality

- What is the best use case for piston filling machines? Master Viscous & Chunky Product Filling

- What are the core benefits of integrating automated honey-filling machines? Scale Your Production and Brand Value