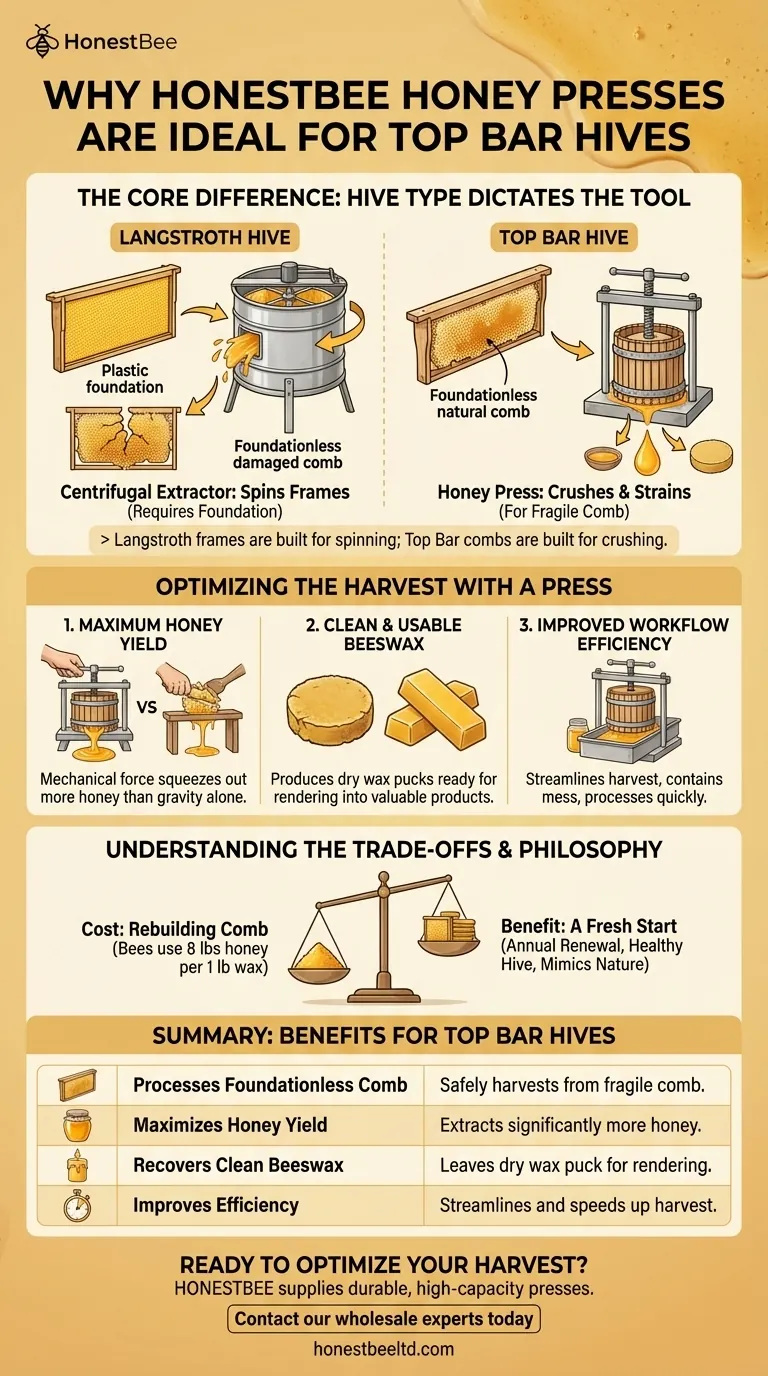

At its core, a honey press is the ideal tool for Top Bar hive beekeepers because this hive style produces foundationless comb that cannot be processed in a standard centrifugal extractor. The "crush and strain" method employed by a press is the only practical way to separate honey and wax from the delicate, natural comb built in a Top Bar hive, maximizing your honey yield while also recovering valuable beeswax.

The fundamental choice is not between a press and an extractor, but rather dictated by your hive type. Langstroth frames are built for spinning; Top Bar combs are built for crushing. A honey press is simply the most efficient tool for the job required by a Top Bar hive.

Why Centrifugal Extractors Don't Work for Top Bars

The Standard Method: Centrifugal Extraction

In conventional beekeeping with Langstroth hives, frames contain a "foundation" of plastic or wired wax. Bees build their comb on this rigid structure.

During harvest, a beekeeper uncaps the honey cells and places the entire frame into a centrifugal extractor. This machine spins the frames at high speed, using inertia to sling honey out of the cells without destroying the underlying comb.

The Top Bar Hive Difference: Foundationless Comb

Top Bar hives are different. The bees build their comb by drawing it down naturally from a simple wooden bar, with no internal wires or plastic foundation for support.

This natural comb is beautiful and functional inside the hive, but it is extremely fragile. If you placed a full Top Bar comb into a centrifugal extractor, it would immediately disintegrate under the rotational force, creating a mess of honey, wax, and bee larvae.

The Necessary Alternative: Crush and Strain

Because spinning is not an option, the only way to harvest honey from a Top Bar comb is to crush it entirely.

This process breaks open every honey cell, releasing the liquid gold. The resulting mixture of honey and wax must then be strained to separate the two components. A honey press is the most powerful and efficient tool for this specific task.

How a Honey Press Optimizes the Harvest

Maximum Honey Yield

While you can crush and strain comb by hand using buckets and cheesecloth, this manual process is slow and inefficient. A significant amount of honey remains trapped in the wax.

A honey press uses mechanical force—typically a large screw—to exert immense pressure on the crushed comb. This squeezes out far more honey than gravity straining alone, dramatically increasing your total yield from the same amount of comb.

Clean and Usable Beeswax

The secondary output of pressing is a compact, dry puck of beeswax. After pressing, the wax has very little residual honey, making it clean and ready for rendering.

This high-quality wax is a valuable resource for making candles, balms, wood polish, or for selling as a separate product.

Improved Workflow Efficiency

For beekeepers with more than one or two hives, a press streamlines the entire harvest day. It contains the mess and processes large batches of comb far more quickly than manual methods.

Larger presses can hold several gallons of honey in their base, allowing for continuous operation without needing to stop and drain the honey after every batch.

Understanding the Trade-offs

The "Cost" of Rebuilding Comb

The primary trade-off of the crush and strain method is that the bees must rebuild all new comb after every harvest. It is estimated that bees consume around 8 pounds of honey to produce 1 pound of wax.

In contrast, reusing drawn comb from a centrifugal extractor gives the bees a massive head start on refilling it with honey, often leading to larger honey crops in established Langstroth operations.

The Benefit of a Fresh Start

However, constantly cycling out old comb has its advantages. It prevents the hive from accumulating pesticides, environmental toxins, and disease spores that can build up in wax over time.

Many natural beekeepers see this annual renewal of comb as a key element of maintaining a healthy, vibrant colony. It more closely mimics the natural cycle of a wild bee colony.

Making the Right Choice for Your Goal

The right tool is determined entirely by your hive type and beekeeping philosophy.

- If your primary focus is harvesting from a Top Bar hive: A honey press is your most effective and efficient tool for maximizing honey yield and cleanly recovering beeswax.

- If your primary focus is maximizing honey production in Langstroth hives: A centrifugal extractor is the industry standard for preserving drawn comb and enabling bees to refill it quickly.

- If you are a small-scale hobbyist with only one Top Bar hive: You can begin with manual crush and strain methods, but be aware that you will leave a notable amount of honey behind in the wax.

Ultimately, aligning your equipment with your hive management style ensures a more effective and enjoyable harvest.

Summary Table:

| Feature | Benefit for Top Bar Hive Beekeepers |

|---|---|

| Processes Foundationless Comb | Safely harvests honey from fragile, natural comb that cannot be spun in an extractor. |

| Maximizes Honey Yield | Mechanical pressure extracts significantly more honey than manual crush and strain methods. |

| Recovers Clean Beeswax | Leaves a dry wax puck ready for rendering into candles, balms, or for sale. |

| Improves Efficiency | Streamlines harvest day, contains mess, and processes large batches quickly. |

Ready to optimize your Top Bar hive harvest?

As a commercial beekeeper or distributor, efficiency and yield are paramount. HONESTBEE supplies durable, high-capacity honey presses designed for the specific needs of Top Bar hive operations. Our equipment helps you maximize honey recovery and produce a valuable, clean beeswax byproduct.

Contact our wholesale experts today to discuss how our beekeeping supplies can enhance your operation's productivity and profitability.

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How is a fruit or honey press used to extract honey from comb? Master Cold-Pressed Honey for Maximum Purity

- Can the Honey Press be used for purposes other than honey extraction? Unlock Its Versatility for Juicing & Herbal Projects

- What are the benefits of using a honey press for Warré or Top Bar beehives? Maximize Your Natural Harvest

- What types of combs are best suited for the honey press? Salvage Honey from Old or Damaged Combs

- Why do beekeepers prefer crushed honey? Unlock a Richer, More Complex Flavor Profile

- How does pressing honey help preserve its quality? Retain Rich Flavors and Nutrients Through Low-Aeration Extraction

- How are honey presses beneficial for large beekeeping operations? Maximize Yield & Efficiency

- How does an industrial honey pressing machine affect honey composition? Maximize Nutritional Density vs Extraction