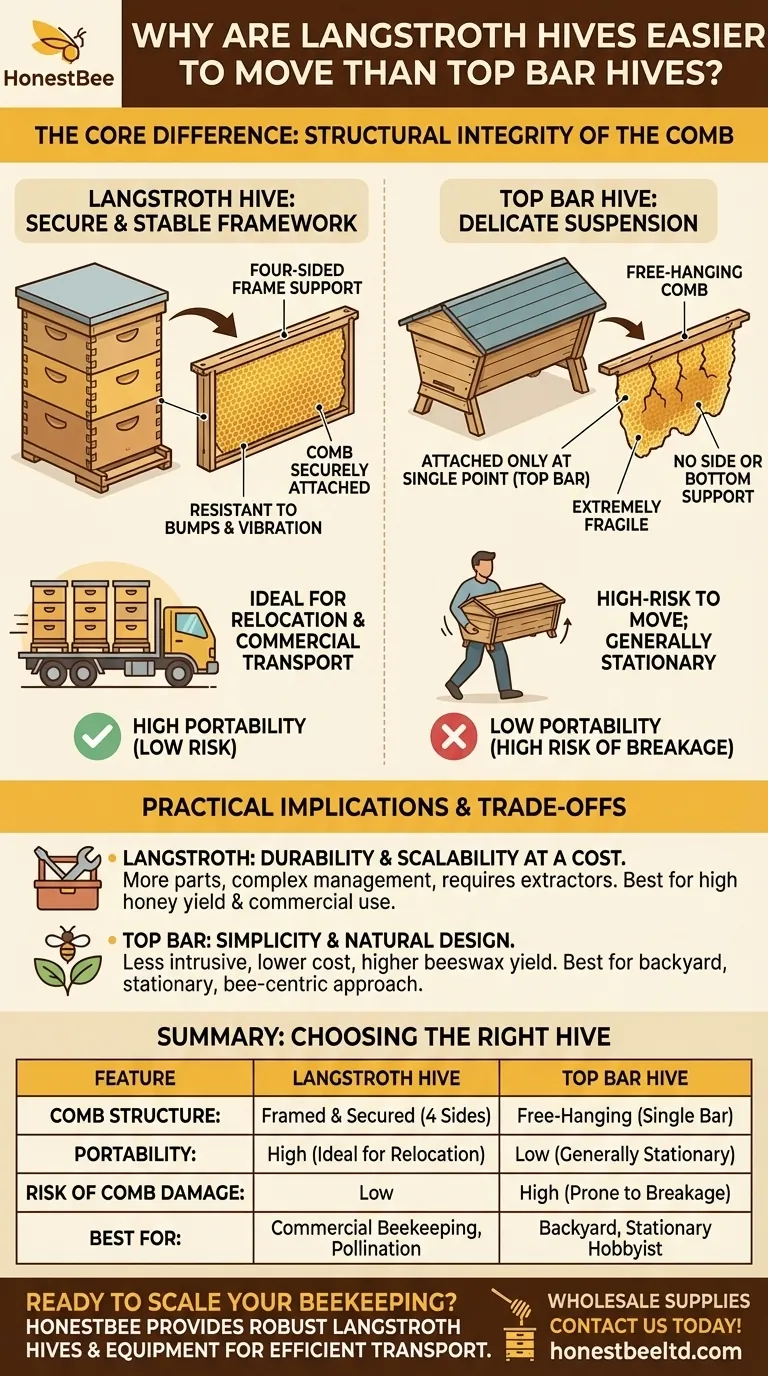

At its core, Langstroth hives are easier to move because their internal design secures the honeycomb within a rigid, four-sided frame. This makes the entire structure stable and resistant to bumps. Top bar hives, in contrast, feature delicate combs that hang freely from a single bar at the top, making them extremely fragile and prone to breaking during transport.

The critical difference in portability is not the hive box itself, but the structural integrity of the comb inside. Langstroth hives are engineered for stability and management, while top bar hives are designed to more closely mimic a natural bee colony.

The Core Difference: Framed vs. Free-Hanging Comb

The reason one hive is robust and the other is delicate comes down to a fundamental choice in how the bees are encouraged to build their home.

The Langstroth Design: A Secure Framework

In a Langstroth hive, each sheet of honeycomb is built inside a rectangular, four-sided frame, much like a painting in a picture frame.

This frame provides complete support to the wax comb on all sides. The comb is securely attached and cannot easily break free.

Because of this, the individual frames—and the boxes that hold them—are solid, durable units that can withstand the vibrations and tilting associated with being loaded onto a vehicle.

The Top Bar Design: A Delicate Suspension

Top bar hives operate on a simpler principle. A series of wooden bars are laid across the top of a long, trough-like box.

The bees build their comb downward from each bar, with the wax hanging freely into the open space below, similar to a curtain hanging from a rod.

This "free comb" is only attached at a single point: the top bar. It has no side or bottom support, making it incredibly fragile. Any sudden jolt or excessive tilting can cause the heavy, honey-filled comb to detach and fall.

Practical Implications of Hive Structure

This single design difference has significant consequences for how a beekeeper manages their hive.

Why Transportation is Simpler with Langstroth

The modular, framed design of a Langstroth hive makes it ideal for relocation. Beekeepers can strap the boxes together, secure the entrance, and confidently place them on a truck.

The internal structure is so secure that this is the standard method used for commercial pollination, where millions of hives are transported across the country.

The Challenge of Relocating Top Bar Hives

Moving a top bar hive is a high-risk operation. The beekeeper must carry it with extreme care, keeping it as level as possible to prevent the combs from swinging and breaking.

A detached comb can crush bees, destroy brood, and spill honey throughout the hive, creating a catastrophic mess that can doom the colony. For this reason, top bar hives are generally considered stationary.

Understanding the Trade-offs: Portability vs. Natural Design

The ease of movement is just one factor in a larger set of design trade-offs between the two systems.

The Cost of Langstroth's Structure

The stability of a Langstroth hive comes from its complexity. It has many parts, including multiple boxes, frames, covers, and often a queen excluder to manage the queen's laying pattern.

Inspections are more involved, and harvesting honey requires specialized and expensive equipment like extractors to spin the honey out while preserving the comb.

The Benefit of Top Bar's Simplicity

The top bar hive's main appeal is its simplicity and low cost. It is a single, self-contained unit that is far less intrusive for the bees.

The bees build comb as they would in nature, and honey harvesting is done by simply cutting the comb off the bar and crushing it, which requires only basic kitchen utensils. While this method destroys the comb, it yields a higher amount of valuable beeswax.

Making the Right Choice for Your Goal

Ultimately, the choice between a Langstroth and a top bar hive depends entirely on your beekeeping philosophy and logistical needs.

- If your primary focus is honey production or you need to move your hives: The Langstroth hive is the clear and logical choice due to its durability, scalability, and higher honey yield.

- If your primary focus is backyard beekeeping with minimal intervention and cost: A top bar hive is an excellent option for a more "bee-centric" approach, provided you plan to keep it in one location.

Choosing the right hive is about aligning the equipment's design with your specific goals as a beekeeper.

Summary Table:

| Feature | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Comb Structure | Framed & Secured on 4 Sides | Free-Hanging from a Single Bar |

| Portability | High (Ideal for Relocation) | Low (Generally Stationary) |

| Risk of Comb Damage | Low | High (Prone to Breakage) |

| Best For | Commercial Beekeeping, Pollination Services | Backyard, Stationary Hobbyist Beekeeping |

Ready to scale your beekeeping operations with durable, portable equipment?

As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides the robust Langstroth hives and equipment you need for efficient, large-scale beekeeping and safe transport. Our wholesale-focused operations ensure you get reliable, high-quality supplies to support your business.

Contact HONESTBEE today to discuss your equipment needs and boost your apiary's productivity!

Visual Guide

Related Products

- Professional Grade Foldable Beehive Handles

- Professional Hive Top Bee Feeder for Beekeeping

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Professional Drop-Style Hive Handles for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What are the technical advantages of moveable-frame hives for honeybee health? Optimize Your Apiary Management

- Why is the implementation of movable frame hives necessary for internal inspections? Master Precision Colony Care

- Why is the movable-frame hive critical for beekeeping? Boost Honey Production with Advanced Modern Hive Management

- What is the significance of the moveable-frame honey beehive? Revolutionizing Modern Beekeeping with Bee Space

- What are the primary advantages of using a Movable Frame Bee Hive? Boost Your Honey Yield and Hive Health