At its core, filling accuracy is a direct measure of an operation's profitability and professionalism. It is the critical factor that ensures the correct volume of honey is dispensed into every container. This precision directly prevents costly product waste, ensures compliance with packaging regulations, and builds customer trust by delivering a consistent and reliable product.

In honey production, filling accuracy isn't just a technical specification; it's the foundation of financial control. Every fraction of a gram saved from overfilling is pure profit, while consistent underfilling risks your brand's reputation and legal standing.

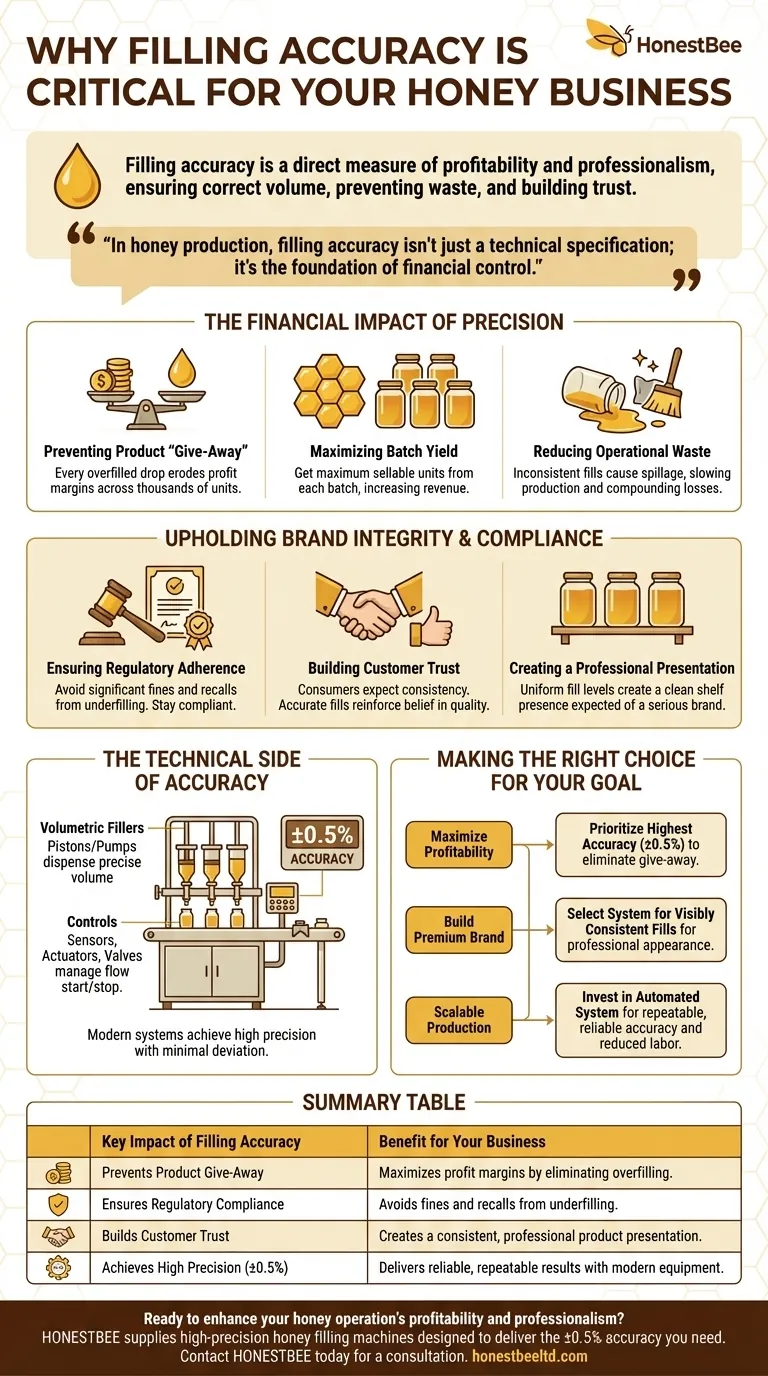

The Financial Impact of Precision

The most immediate and significant reason to prioritize filling accuracy is its direct effect on your bottom line. In a business of volume, small deviations accumulate into major financial consequences.

Preventing Product "Give-Away"

Every drop of honey that is overfilled is product you are giving away for free. While a single overfilled jar seems trivial, this loss is magnified across thousands of units, directly eroding your profit margins.

Maximizing Batch Yield

High accuracy ensures you get the maximum number of sellable units from each batch of honey. Inaccurate filling leads to fewer jars per batch, which means lost potential revenue from the raw product you've already produced.

Reducing Operational Waste

Inconsistent fills can cause secondary problems, such as spillage on containers that complicates sealing and labeling. This creates additional cleanup, slows down the production line, and can lead to rejected packages, compounding your losses.

Upholding Brand Integrity and Compliance

Beyond direct costs, filling accuracy is fundamental to how your brand is perceived in the market and viewed by regulators.

Ensuring Regulatory Adherence

Governments enforce strict "weights and measures" laws for packaged goods. Consistently underfilling jars, even slightly, can lead to significant fines, mandatory recalls, and legal action, damaging both your finances and your reputation.

Building Customer Trust

Consumers expect consistency. Jars on a shelf with visibly different fill levels signal a lack of quality control and professionalism. A consistent, accurate fill reinforces the customer's belief that they are buying a high-quality product from a reputable producer.

Creating a Professional Presentation

Accurate filling is a key component of a professional-looking product. It ensures every jar looks identical, creating the clean, uniform shelf presence expected of a serious brand.

The Technical Side of Accuracy

Modern filling machines use specific technologies to achieve the precision required for a profitable and compliant operation.

How Volumetric Fillers Work

Most honey fillers are volumetric, meaning they are designed to dispense a precise, pre-set volume of product. An operator enters the target volume, and the machine's internal mechanisms, like pistons or pumps, are calibrated to dispense exactly that amount.

The Role of Controls

This process is managed by a system of sensors, actuators, and valves. These components work together to start and, crucially, stop the flow of honey at the exact right moment to hit the target volume with minimal deviation.

Defining "High Accuracy"

Advanced automatic honey filling machines can achieve a very high degree of precision. It is common for high-quality systems to operate with a filling accuracy of ±0.5%, ensuring minimal variation between containers.

Making the Right Choice for Your Goal

Selecting equipment requires aligning its technical capabilities with your specific business objectives.

- If your primary focus is maximizing profitability: Prioritize a machine with the highest documented filling accuracy (e.g., ±0.5%) to eliminate product give-away and maximize your yield.

- If your primary focus is building a premium brand: Select a system that guarantees visibly consistent fill levels to ensure a professional, uniform appearance on the shelf.

- If your primary focus is scalable production: Invest in an automated system where accuracy is repeatable and reliable, reducing labor costs and eliminating human error.

Ultimately, investing in filling accuracy is an investment in the long-term financial health and credibility of your business.

Summary Table:

| Key Impact of Filling Accuracy | Benefit for Your Business |

|---|---|

| Prevents Product Give-Away | Maximizes profit margins by eliminating overfilling. |

| Ensures Regulatory Compliance | Avoids fines and recalls from underfilling. |

| Builds Customer Trust | Creates a consistent, professional product presentation. |

| Achieves High Precision (±0.5%) | Delivers reliable, repeatable results with modern equipment. |

Ready to enhance your honey operation's profitability and professionalism?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-precision honey filling machines designed to deliver the ±0.5% accuracy you need to maximize yield and protect your brand. Our wholesale-focused operations ensure you get reliable, durable equipment for scalable production.

Contact HONESTBEE today for a consultation on the right filling solution for your business goals.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How does a premade pouch packaging machine for honey operate? Optimize Your Honey Filling Efficiency

- How do automated honey-filling machines ensure that honey products meet industrial quality standards? Boost Consistency

- How does automated honey filling equipment contribute to the industrial value of honey? Scale Your Premium Honey Brand

- What is the importance of honey filling machines? Scale Your Production and Ensure Product Integrity

- What is the function of the vertical sealing bar in a honey stick machine? Ensure Leak-Proof Honey Sticks

- What is the function of automatic honey filling machines? Transform Bulk Honey into High-Value Retail Assets

- What role does precision filling equipment play in cost control? Maximize Honey Profits & Market Growth

- How do I choose a packaging machine? A Systematic Guide to Aligning with Your Production Needs