Properly drying your honey extractor before storage is a critical step for any beekeeper. The primary and most immediate reason is to prevent the growth of mold and mildew. Any residual moisture, especially when combined with trace amounts of honey, creates an ideal breeding ground for fungi that can contaminate future honey harvests and damage your equipment.

The act of drying your extractor is more than a simple chore; it is the final step in a vital sanitation process that safeguards your honey's purity, protects your bees from disease, and preserves the long-term value of your investment.

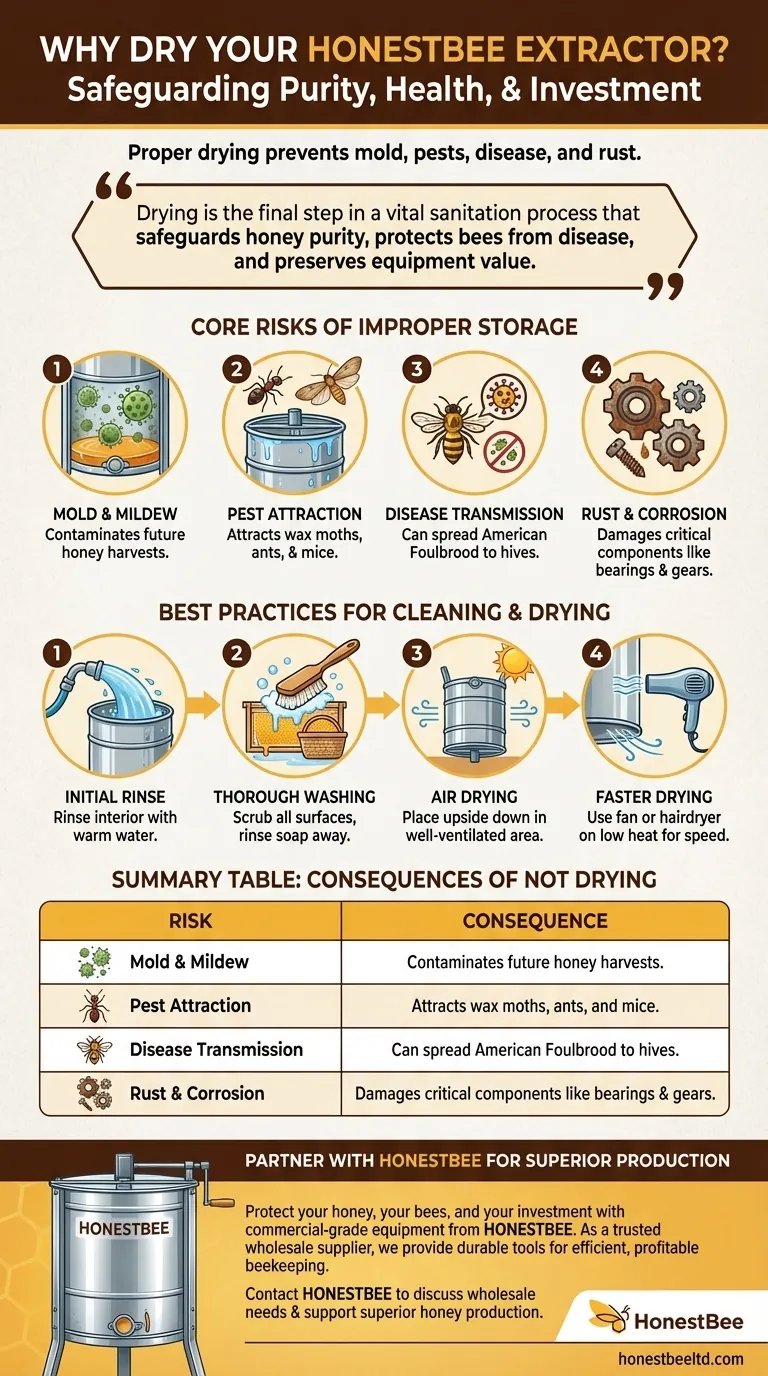

The Core Risks of Improper Storage

Failing to properly clean and dry your extractor introduces several preventable risks that can affect your honey, your bees, and your equipment. Understanding these risks highlights the importance of this final step.

Preventing Mold and Mildew

The most direct consequence of storing a damp extractor is mold growth. Microscopic spores will flourish in the moist, sugar-rich environment, leading to contamination that can ruin the taste and safety of your next honey harvest.

Deterring Pests

Residual honey and moisture are powerful attractants for pests like wax moths, ants, and mice. A thoroughly cleaned and dried extractor is inert and uninteresting, preventing infestations during the off-season.

Halting Disease Transmission

A dirty or damp extractor can harbor pathogens like American Foulbrood spores. Storing the equipment without proper sanitation can lead to the transmission of these devastating diseases to your healthy colonies the following season.

Avoiding Rust and Corrosion

While many modern extractors are made of stainless steel, components like bearings, gears, and screws can still be susceptible to rust and corrosion if left wet. Proper drying is essential for preventing premature wear and tear.

Best Practices for Cleaning and Drying

A consistent and thorough process will ensure your extractor is always ready for the next use.

The Initial Rinse

Immediately after you finish extracting, rinse the interior with a hose (preferably with warm water) to remove the majority of the honey. This makes the subsequent washing step much easier.

Thorough Washing

Use a soft brush or cloth with a food-safe detergent to scrub all interior surfaces, including the basket and the honey gate. Ensure you rinse away all soap residue completely.

The Drying Process

Your goal is to eliminate every last drop of moisture. Air drying is the most common and effective method. Place the extractor upside down in a clean, sunny, and well-ventilated area to allow water to drain and evaporate.

For Faster Results

If you are short on time, you can use a fan or even a hairdryer on a low-heat setting to speed up the process. Focus on areas where water can pool, such as the bottom seam and around the honey gate.

Common Pitfalls to Avoid

Even with good intentions, simple mistakes can undermine your efforts. Being aware of them is key to proper maintenance.

The "Good Enough" Rinse

A quick rinse with cold water is not sufficient. This often leaves a thin, sticky film of honey that will still attract pests and fuel mold growth.

Using Abrasive Cleaners

Avoid harsh chemicals or abrasive scouring pads that can scratch the stainless steel. These microscopic scratches can become locations for bacteria to hide and grow.

Neglecting the Small Parts

It is easy to focus on the main drum and forget about the honey gate, lid, and internal basket. These components must also be cleaned and dried with the same level of care.

Making the Right Choice for Your Goal

Based on your priorities, here is how to frame the importance of this task.

- If your primary focus is honey purity: Thorough drying is non-negotiable to prevent mold spores from contaminating your next harvest.

- If your primary focus is bee health: A sanitized and dry extractor is critical for preventing the carryover of diseases that could devastate your hives.

- If your primary focus is equipment longevity: Complete drying prevents rust and corrosion, significantly extending the working life of your extractor.

Taking these simple sanitation steps after each use ensures your extractor remains a reliable tool, not a future liability.

Summary Table:

| Risk of Not Drying | Consequence |

|---|---|

| Mold & Mildew | Contaminates future honey harvests. |

| Pest Attraction | Attracts wax moths, ants, and mice. |

| Disease Transmission | Can spread American Foulbrood to hives. |

| Rust & Corrosion | Damages critical components like bearings and gears. |

Protect your honey, your bees, and your investment with the right equipment from HONESTBEE.

As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, we understand that your success depends on durable, reliable tools. Proper maintenance starts with quality equipment designed for easy cleaning and long-term performance.

Let HONESTBEE be your partner in efficient, profitable beekeeping. We provide the commercial-grade extractors and supplies you need to ensure every harvest is pure and your equipment lasts for seasons to come.

Contact HONESTBEE today to discuss your wholesale needs and discover how our products support superior honey production and equipment care.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is a honey extractor and what is its principle of operation? Efficient Harvesting via Centrifugal Force

- How is honey removed from the uncapped frames? Use Centrifugal Force for Maximum Efficiency

- How does specialized extraction equipment contribute to by-product utilization? Scale Your Profits with Precision

- Why is professional honey extraction equipment essential? Protect Purity and Bioactivity in Your Harvest

- How do industrial-grade honey extractors ensure efficiency? Boost Your Harvest While Protecting Colony Health

- What technical advantages do centrifugal honey extractors offer? Boost Your Apiary's Efficiency and Honey Yield

- How does a honey extractor function? Master the Art of Efficient Centrifugal Honey Harvesting

- How do Specialized Extraction Tools for honey, pollen, and propolis support sustainable beekeeping? Boost Hive Yield