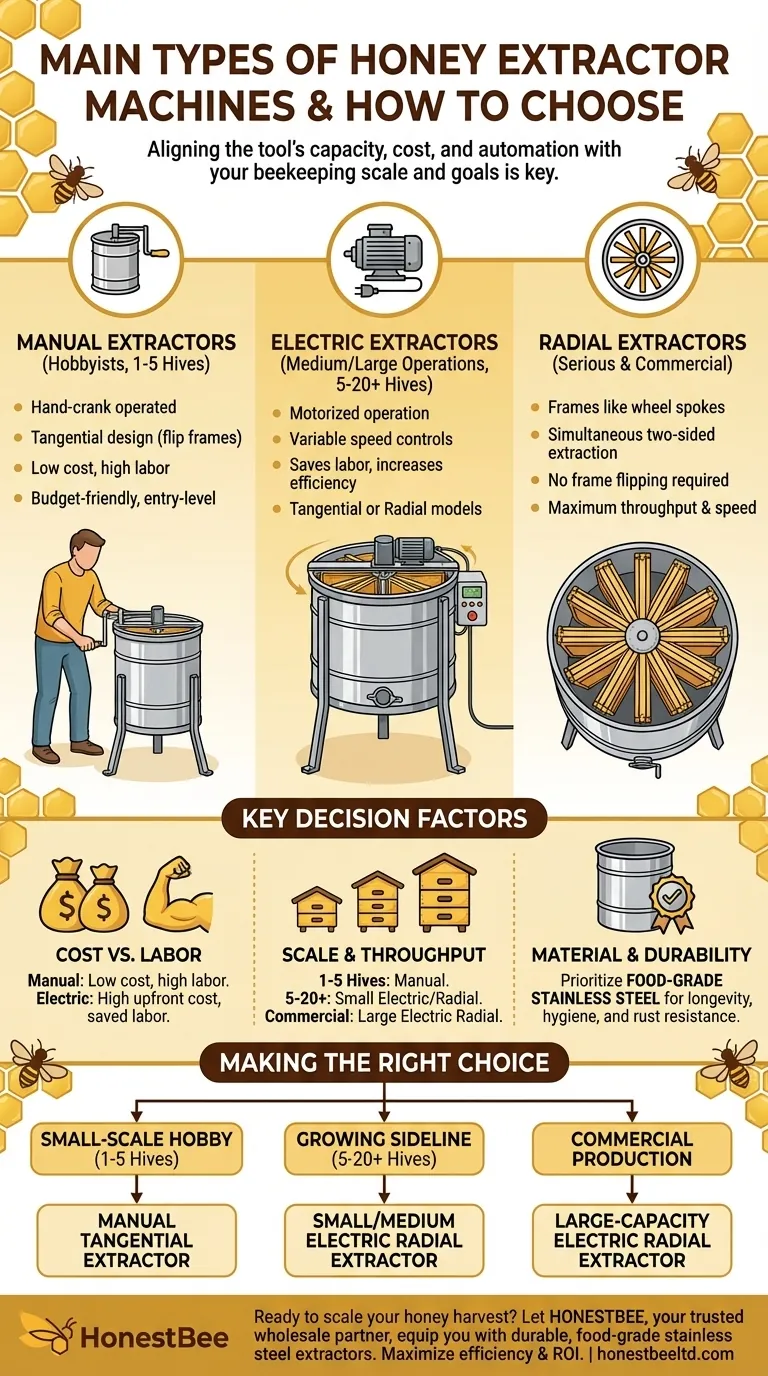

The primary types of honey extractor are manual, electric, and radial. Manual extractors are operated by a hand crank and are best suited for hobbyists with a few hives due to their lower cost and simplicity. Electric extractors use a motor to automate the spinning process, making them ideal for medium to large-scale operations where efficiency and time are critical. Radial extractors, which are typically electric, position the frames like spokes in a wheel, allowing honey to be extracted from both sides simultaneously for maximum throughput.

Choosing the right honey extractor is not about finding the "best" machine, but about aligning the tool's capacity, cost, and level of automation with the scale of your beekeeping operation and your personal goals.

Deconstructing the Extractor Types

To make an informed decision, it's essential to understand the functional differences between each type of extractor and the design principles that govern their efficiency.

Manual Extractors: The Hands-On Approach

Manual extractors are the entry point for most new beekeepers. They are operated by a hand crank, giving you direct, physical control over the extraction speed.

These machines are typically tangential, meaning the frames sit flat against the wall of the drum. This design requires you to spin one side, stop, flip the frames, and then spin the other side.

They are an excellent, budget-friendly choice for those with only a handful of hives, where the time and physical effort required are manageable.

Electric Extractors: Automating for Efficiency

Electric extractors replace the hand crank with a motor, drastically reducing labor and increasing the speed of the extraction process.

These machines are the standard for any beekeeper looking to scale beyond a small hobby, saving significant time and physical strain during harvest.

Most electric models offer variable speed controls, allowing you to start slowly to prevent comb damage before ramping up to full extraction speed.

Radial vs. Tangential: A Critical Design Distinction

The orientation of the frames inside the drum is a crucial factor in an extractor's efficiency. This distinction applies to both manual and electric models, but is most prominent in larger electric units.

A tangential extractor places the frame with one side facing outward. This is simple but requires flipping the frames midway through the process.

A radial extractor places the frames like spokes in a wheel. Centrifugal force extracts honey from both sides of the comb simultaneously, making the process significantly faster and eliminating the need to flip frames. This design is standard for serious and commercial operations.

Key Factors in Your Decision

Choosing the right machine involves balancing several practical considerations. Thinking through these trade-offs will lead you to the most logical choice for your needs.

Cost vs. Labor

This is the most fundamental trade-off. A manual extractor has a low upfront cost but demands a high investment of your time and physical energy.

An electric extractor has a significantly higher upfront cost but pays for itself in saved labor and increased efficiency, allowing you to process more honey in less time.

Scale and Throughput

Your choice should directly reflect the number of hives you manage. A 2-4 frame manual extractor is perfectly adequate for 1-5 hives.

If you manage 5-20 hives, a small electric tangential or radial extractor becomes a worthwhile investment. For operations larger than that, a high-capacity electric radial extractor is a necessity.

Material and Durability

Always prioritize extractors made from food-grade stainless steel. This material is far superior to plastic or painted steel because it resists rust, won't leach chemicals, and is much easier to clean and sanitize.

A stable base and high-quality components, like a steel honey gate instead of plastic, also contribute to the machine's longevity and ease of use.

Making the Right Choice for Your Operation

Use your operational goals as the primary guide for selecting a honey extractor.

- If your primary focus is a small-scale hobby (1-5 hives): A simple and cost-effective manual tangential extractor is the most practical choice.

- If your primary focus is growing a serious sideline business (5-20+ hives): Invest in a small-to-medium-sized electric radial extractor to save significant time and labor.

- If your primary focus is commercial production: A large-capacity, stainless steel electric radial extractor is the only viable option for efficient, high-volume processing.

Ultimately, the right extractor is a tool that respects your hard work and the incredible productivity of your bees.

Summary Table:

| Extractor Type | Best For | Key Feature |

|---|---|---|

| Manual | Hobbyists (1-5 hives) | Hand-crank operation, budget-friendly |

| Electric | Medium/Large-scale operations | Motorized for efficiency, saves labor |

| Radial | Serious & Commercial beekeepers | Extracts both sides of frames simultaneously |

Ready to scale your honey harvest? Let HONESTBEE, your trusted wholesale partner, equip you with the right extractor. We supply durable, food-grade stainless steel honey extractors and beekeeping equipment to commercial apiaries and distributors. Our experts will help you choose the perfect machine to maximize your efficiency and ROI. Contact our team today for a personalized quote!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What is the proper procedure for maintaining a centrifuge honey extractor? Expert Tips for Longevity and Hygiene

- What roles do centrifuges and multi-stage filtration equipment play in honey extraction? Expert Analysis

- What are some tips for efficient honey extraction using a centrifuge? Maximize Your Yield and Protect Your Comb

- What are the key features and benefits of a stainless steel honey extractor? Upgrade to Professional Purity

- How can a pressure washer be used to clean a honey extractor? A Guide to Safe and Efficient Cleaning

- What are the general steps for cleaning a honey extractor? Ensure Purity & Equipment Longevity

- What are the advantages of using a horizontal beehive configuration regarding honey extraction? Maximize Your Yield

- Why use professional centrifugal honey extractors in rural areas? Boost Turnover & Save Colony Energy