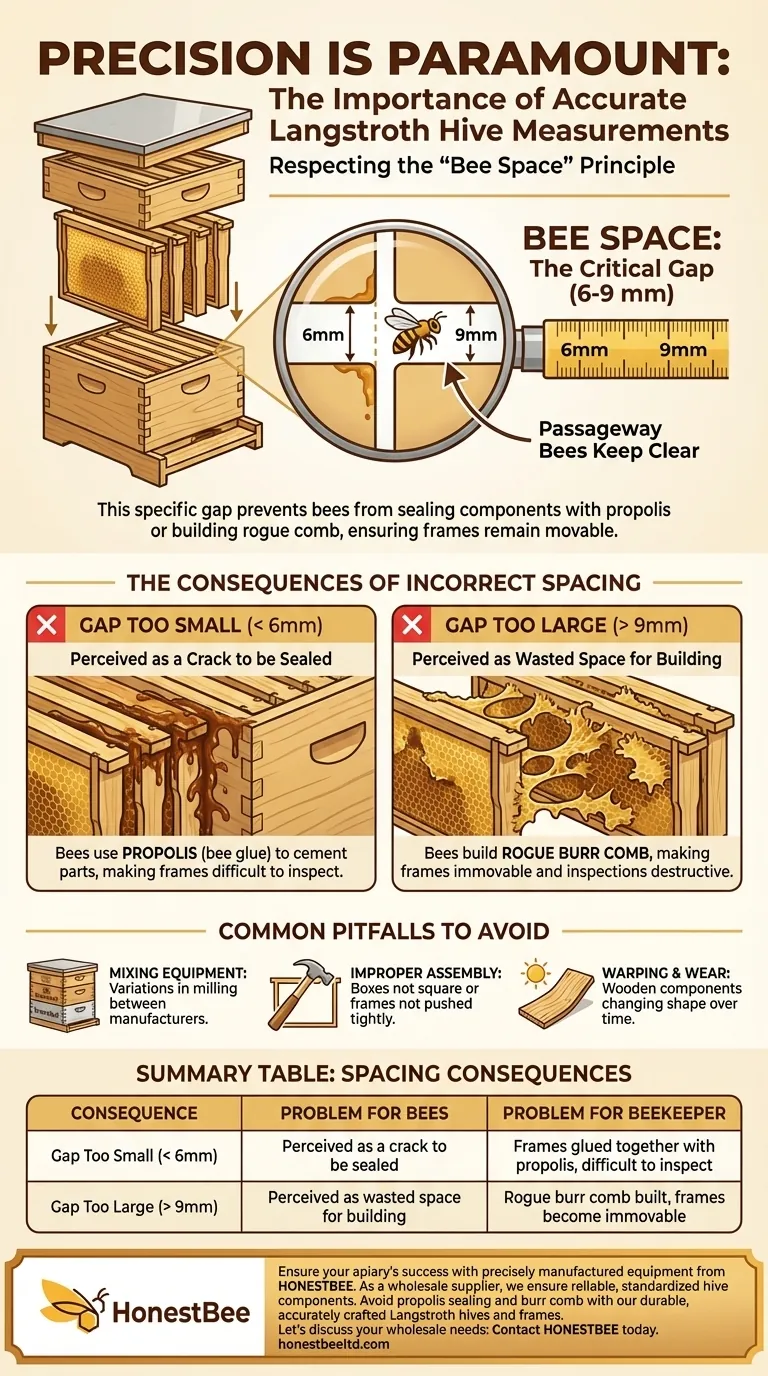

The short answer is this: Maintaining accurate measurements in a Langstroth hive is critical for respecting a principle known as bee space. This specific gap, between 6 and 9 mm, prevents bees from sealing components together with propolis or building rogue comb, ensuring the hive's frames remain movable for inspection and management.

The entire modern system of beekeeping is built on a single, precise measurement. Deviating from this "bee space" fundamentally breaks the hive's design, turning a manageable colony into a frustrating, glued-together box that is difficult to inspect without harming the bees.

The Genius of "Bee Space"

To understand the importance of measurements, we must first understand the foundational concept that makes the Langstroth hive revolutionary. It’s not about the boxes themselves, but the space between the components.

Defining Bee Space

Bee space is a term for a gap measuring between 1/4 and 3/8 of an inch (roughly 6-9 mm). When bees encounter a space within this range, they recognize it as a passageway and keep it clear.

This discovery by Rev. Lorenzo Langstroth in 1851 changed beekeeping forever. He designed a hive with frames that were suspended inside a box, surrounded on all sides by this exact measurement.

The Beekeeper's Advantage

Because the bees keep this space clear, the frames do not get glued to the hive walls or to each other. This allows a beekeeper to easily remove, inspect, and manipulate individual frames without destroying the comb or angering the colony.

This system of removable frames is the cornerstone of modern apiculture, enabling hive inspections, disease management, and honey harvesting with minimal disruption.

The Consequences of Incorrect Spacing

When the hive's internal measurements deviate from the precise bee space, bees revert to their natural instincts, creating significant problems for the beekeeper.

Gaps Too Small (< 6mm)

If a gap is smaller than the recognized bee space, bees perceive it as a crack in their nest. Their instinct is to seal it against drafts and invaders.

They do this using propolis, a resinous "bee glue" they collect from trees. This substance is incredibly strong and will cement frames and boxes together, making them extremely difficult to separate.

Gaps Too Large (> 9mm)

If a gap is larger than bee space, bees see it as wasted, unstructured space. Their instinct is to build it out with wax.

They fill these larger voids with what is known as burr comb or brace comb. This rogue comb connects frames to each other or to the hive body, making it impossible to remove a frame without cutting through the comb, often spilling honey and destroying brood in the process.

Common Pitfalls to Avoid

Maintaining bee space requires more than just buying a standard hive; it requires vigilance. Even small deviations can cascade into major management headaches.

Mixing Equipment

A primary cause of spacing issues is mixing hive components from different manufacturers. While most adhere to the Langstroth standard, slight variations in milling can create gaps that are too large or too small.

Improper Assembly

Even a perfectly manufactured hive kit can have problems if it's not assembled correctly. Boxes that aren't perfectly square or frames that aren't pushed tightly together can violate bee space.

Warping and Wear

Over time, wooden hive components can warp or wear down from use. What was once a perfect measurement can change with exposure to the elements, requiring beekeepers to monitor and replace aging equipment.

Ensuring Precision in Your Apiary

Your approach to hive measurements directly impacts your efficiency and the well-being of your bees. The goal is to work with the bees' natural tendencies, not against them.

- If your primary focus is efficient inspections: Standardize your equipment from a single, reputable supplier to ensure all measurements are consistent across your apiary.

- If your primary focus is colony health: Meticulous attention to bee space minimizes the need for forceful, jarring hive manipulations, reducing stress on the bees and preventing damage to the brood nest.

- If your primary focus is building your own equipment: Adhere strictly to proven Langstroth blueprints, as even a few millimeters of deviation can compromise the entire design.

Ultimately, respecting the hive's geometry is respecting the bees' innate behavior, creating a more harmonious and productive partnership between the beekeeper and the colony.

Summary Table:

| Consequence of Incorrect Spacing | Problem for Bees | Problem for Beekeeper |

|---|---|---|

| Gap Too Small (< 6mm) | Perceived as a crack to be sealed | Frames glued together with propolis, difficult to inspect |

| Gap Too Large (> 9mm) | Perceived as wasted space for building | Rogue burr comb built, frames become immovable |

Ensure your apiary's success with precisely manufactured equipment from HONESTBEE.

As a wholesale supplier to commercial apiaries and beekeeping equipment distributors, we understand that your productivity depends on reliable, standardized hive components that strictly adhere to the critical bee space measurement. Avoid the costly problems of propolis sealing and burr comb with our durable, accurately crafted Langstroth hives and frames.

Let's discuss your wholesale needs: Contact HONESTBEE today to learn how our equipment supports efficient, large-scale beekeeping operations.

Visual Guide

Related Products

- Stainless Steel 9 Frame Hive Spacer Durable Precise for Commercial Beekeeping

- Durable Plastic Frame Spacer

- Ergonomic Plastic Frame Spacer Tool for Rapid Hive Management Beekeeping

- Professional Castellated Iron Frame Spacer for Multiple Hive Types

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What is 'bee space' and why is it important? The Key to Modern Beekeeping Success

- What is 'bee space' in beehive construction? The Key to Modern, Manageable Beekeeping

- Why is it important to compress frames together in the center of the box after reassembly? Prevent Burr Comb and Hive Chaos

- What to do if bees are building combs between frames? A Guide to Fixing Burr Comb

- Why use 9 frames in a 10 frame hive? Optimize Honey Harvesting with Strategic Spacing