For a honey producer, managing viscosity is the single most critical factor for ensuring both operational efficiency and final product quality. Proper viscosity allows honey to be bottled cleanly and quickly, but achieving it requires a delicate balance. If honey is too thick, it clogs equipment and slows production; if it is made too thin by overheating, its nutritional value and market appeal are destroyed.

The core challenge for any honey producer is reducing viscosity just enough for smooth processing without applying excessive heat. Mastering this balance is the key to protecting the honey's natural quality, preventing equipment failure, and running a profitable operation.

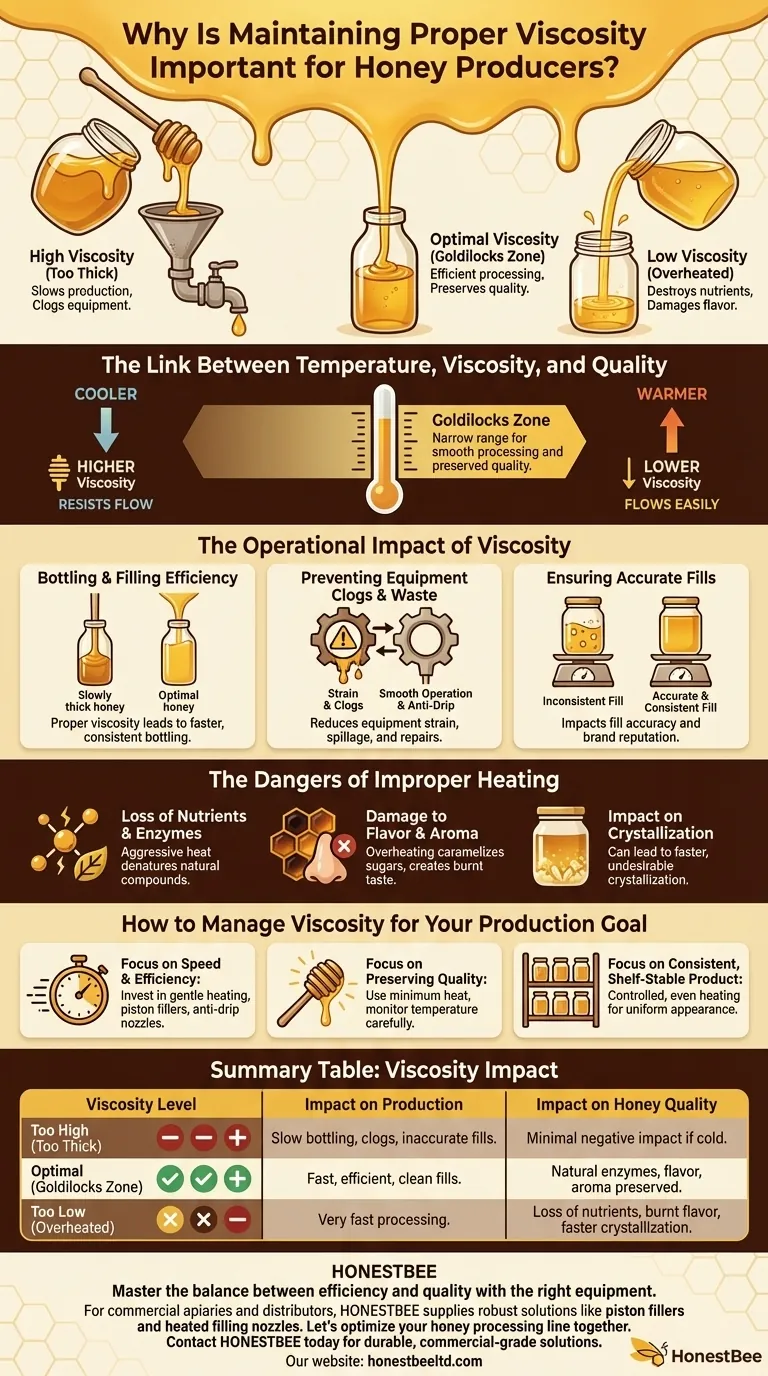

The Link Between Temperature, Viscosity, and Quality

To manage your honey effectively, you must first understand the fundamental relationship between its temperature, its thickness, and its inherent value.

What is Viscosity?

Think of viscosity as honey's resistance to flow. High-viscosity honey is very thick and slow-moving, like cold molasses. Low-viscosity honey is thinner and flows easily.

This property is primarily influenced by two factors: moisture content and, most importantly for a producer, temperature.

How Temperature Changes Everything

Honey viscosity has an inverse relationship with temperature. As you gently warm honey, its viscosity drops significantly, making it flow more freely. Conversely, as it cools, it becomes much thicker and more difficult to handle.

This is why honey processing facilities are often kept warm and why bottling equipment may incorporate gentle heating elements.

Finding the "Goldilocks Zone"

The goal is not simply to heat the honey, but to bring it to a precise temperature—a "Goldilocks Zone." This is a narrow temperature range where the honey is fluid enough for processing but not so hot that its delicate structure is compromised.

Exceeding this zone, even for a short time, can cause irreversible damage to the final product.

The Operational Impact of Viscosity

Controlling viscosity is not just an issue of quality; it is a direct driver of your production line's speed, cleanliness, and cost-effectiveness.

Bottling and Filling Efficiency

Proper viscosity is paramount for bottling. Honey that is too thick will flow slowly, causing long fill times and creating a bottleneck in your production.

When honey is at the correct, lower viscosity, it can be handled by machinery quickly and efficiently, leading to faster, more consistent bottling runs.

Preventing Equipment Clogs and Waste

Forcing high-viscosity honey through pumps and filler nozzles puts immense strain on your equipment, leading to clogs, breakdowns, and costly repairs. Piston fillers and heated filling nozzles are designed specifically to handle viscous liquids, but they still operate best when the honey's thickness is managed.

Furthermore, properly thinned honey works well with anti-drip features, preventing spillage, reducing product waste, and keeping containers clean.

Ensuring Accurate and Consistent Fills

Viscosity directly impacts fill accuracy. Thick honey can trap air pockets and may not settle properly in the jar, leading to inconsistent fill volumes. This can result in giving away product or, worse, short-filling customers.

A consistent, managed viscosity ensures that every jar is filled accurately, protecting your profits and your brand's reputation.

Understanding the Trade-offs: The Dangers of Improper Heating

While heating is necessary to lower viscosity, doing it incorrectly is the fastest way to ruin your honey. The trade-offs are severe and directly impact your bottom line.

Loss of Nutrients and Enzymes

Raw honey is valued for its natural enzymes, antioxidants, and delicate nutritional profile. Aggressive or excessive heat permanently denatures these beneficial compounds.

A "cooked" honey loses the very properties that differentiate high-quality, raw honey from a simple sweetener, drastically reducing its market value.

Damage to Flavor and Aroma

Overheating also caramelizes the honey's natural sugars, creating a darker color and a burnt or "off" flavor. This masks the subtle and unique floral notes that define your honey's origin and character.

Impact on Crystallization

While it may seem counterintuitive, improper heating can negatively affect long-term stability. Flash heating or overheating can damage the honey's natural glucose and fructose balance, sometimes leading to faster, undesirable crystallization patterns after bottling.

How to Manage Viscosity for Your Production Goal

Your approach to managing viscosity should align with your primary business objective.

- If your primary focus is operational speed and efficiency: Invest in processing equipment with integrated, gentle heating systems and features designed for viscous liquids, like piston fillers and anti-drip nozzles.

- If your primary focus is preserving raw honey quality: Use the absolute minimum heat required to make the honey workable, carefully monitoring temperatures to ensure you never degrade its natural enzymes and aroma.

- If your primary focus is a consistent, shelf-stable product: Emphasize controlled, even heating to reach a target viscosity that ensures a uniform appearance and delays crystallization in the final container.

Ultimately, mastering viscosity control is the mark of a skilled honey producer, perfectly balancing the demands of production with the integrity of the product.

Summary Table:

| Viscosity Level | Impact on Production | Impact on Honey Quality |

|---|---|---|

| Too High (Too Thick) | Slow bottling, equipment clogs, inaccurate fills | Minimal negative impact if due to low temperature |

| Optimal (Goldilocks Zone) | Fast, efficient bottling; clean fills; minimal waste | Natural enzymes, flavor, and aroma are preserved |

| Too Low (Overheated) | Very fast processing, but... | Loss of nutrients, burnt flavor, faster crystallization |

Master the balance between efficiency and quality with the right equipment.

For commercial apiaries and distributors, achieving the perfect honey viscosity is the key to a profitable and reputable operation. HONESTBEE supplies the robust, wholesale-focused beekeeping equipment you need to succeed.

Our piston fillers and heated filling nozzles are engineered to handle honey's unique properties, ensuring smooth, fast bottling runs while protecting your product's integrity.

Let's optimize your honey processing line together. Contact HONESTBEE today for durable, commercial-grade solutions.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- What is the effect of heating on honey? Preserve Quality with Controlled Warming

- Why is heating honey sometimes necessary? The Essential Guide to Processing & Quality

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value