You’ve just pulled a massive harvest. The frames are heavy, the air is sweet, and the potential for a profitable season feels immense. But after the pressing is done, you’re left staring at a tank of honey that’s cloudy, full of fine wax particles, and far from the premium product you envisioned. Now begins the slow, costly, multi-stage filtering process that eats into your time and cuts into your margins.

If this scenario feels familiar, you are not alone.

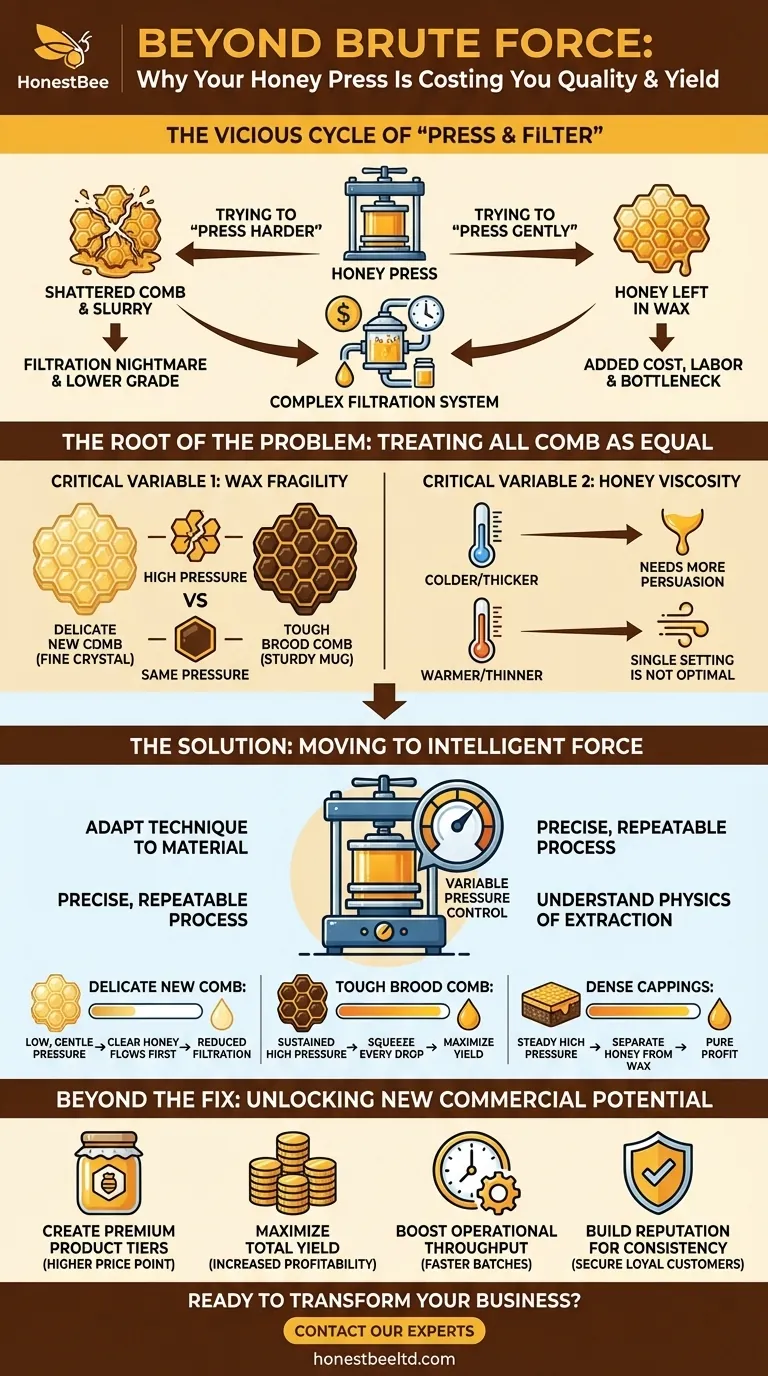

The Vicious Cycle of "Press and Filter"

For many commercial apiaries, honey extraction feels like a constant battle between speed, yield, and quality. The conventional wisdom is often to just press the comb, get the honey out, and deal with the consequences later.

This leads to a series of frustrating and costly struggles:

- Trying to "Press Harder": In an attempt to maximize yield or speed up the process, you apply maximum force from the start. The result? The comb shatters into a slurry, creating a filtration nightmare and lowering the grade of your final product.

- Trying to "Press Gently": Fearing a cloudy product, you use minimal pressure. The honey is clearer, but you can feel the weight of the honey you're leaving behind in the wax, directly impacting your total yield and revenue.

- Investing in More Filtering: You assume the problem is downstream and spend more on complex filtration systems. This adds equipment cost, labor hours, and another bottleneck to your operation, all while treating a symptom, not the cause.

The business consequences are significant. Every hour spent on extra filtering is an hour not spent on processing the next batch. Every percentage point of yield left in the comb is lost profit. And every inconsistent batch damages your brand's reputation for premium quality.

The Root of the Problem: Treating All Comb as Equal

The fundamental mistake in the "press and filter" approach is the assumption that honeycomb is a uniform material. It’s not.

The real culprit behind inconsistent results is applying a one-size-fits-all force to a highly variable material. Think about it: you wouldn't use a sledgehammer for a task requiring a surgical scalpel. The same principle applies here. The physical properties of your comb dictate the force required.

The Two Critical Variables: Fragility and Viscosity

-

Wax Fragility: Freshly drawn comb from a super is incredibly delicate and soft. Think of it like fine crystal. Old, dark brood comb, reinforced with cocoons and propolis, is tough and resilient—more like a sturdy beer mug. Applying the same high pressure to both is guaranteed to shatter the "crystal" while being inefficient for the "mug."

-

Honey Viscosity: The thickness of honey changes dramatically based on temperature and floral source. Colder, thicker honey (like heather) needs more persuasion to flow than warmer, thinner honey. A single pressure setting can't possibly be optimal for both.

This is why your old methods fail. "Pressing harder" shatters the delicate comb. "Pressing gently" fails to extract honey from the tough comb. And your filtration system is simply cleaning up a mess that was created by a lack of control at the most critical stage: the press itself.

The Solution: Moving from Brute Force to Intelligent Force

To solve this problem permanently, you don’t need more force or better filters. You need intelligent force. You need a tool designed with a deep understanding of the physics of honey extraction.

This is precisely why professional-grade honey presses are built with variable pressure control. It’s not a minor feature; it is the core mechanism that allows you to adapt your technique to your material, transforming extraction from a guessing game into a precise, repeatable process.

A press with refined variable pressure control is the embodiment of the solution. It’s designed to directly counter the root cause of your extraction problems:

- For delicate new comb: You can apply a low, gentle, initial pressure. This allows the vast majority of the pure, clear honey to flow out before the wax structure is compromised, drastically reducing your need for filtration.

- For tough brood comb: You have the power to apply sustained, high pressure to squeeze out every last drop of honey from the resilient comb, maximizing your yield.

- For dense cappings: You can use a steady, high-pressure sequence specifically designed to separate the maximum amount of honey from the wax, turning what was once waste into pure profit.

Beyond the Fix: Unlocking New Commercial Potential

When you move beyond the "press and filter" cycle, you don't just solve a problem—you open up new opportunities for your business.

Mastering pressure control allows you to:

- Create Premium Product Tiers: Easily isolate your finest, clearest honey from new comb to sell as a premium, "gravity-strained" or "cold-pressed" product at a higher price point.

- Maximize Total Yield: Confidently extract every possible ounce of honey from your cappings and older comb, increasing the overall profitability of every harvest.

- Boost Operational Throughput: By producing cleaner honey straight from the press, you minimize filtration bottlenecks, freeing up time and labor to process more batches, faster.

- Build a Reputation for Consistency: Deliver a reliably high-quality product, batch after batch, strengthening your brand and securing loyal customers.

This level of control is fundamental to scaling a modern, profitable beekeeping operation. It's time to stop fighting with your honey and start working with it. If you're ready to improve your quality, maximize your yield, and streamline your entire extraction process, our team is here to help you match the right equipment to your specific operational goals.

Contact Our Experts to discuss how a professional-grade honey press can transform your business.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

Related Articles

- The Last Drop: Maximizing Yield and Purity with a Stainless Steel Honey Press

- Ethical Honey Harvesting: Essential Tools and Techniques for Beekeepers

- Why a Honey Press is the Smart Choice for Small-Scale Beekeepers

- The Beekeeper's Dilemma: The Brutal, Beautiful Logic of the Honey Press

- Don't Waste Your Wax: Unlocking Hidden Value from Your Honey Press