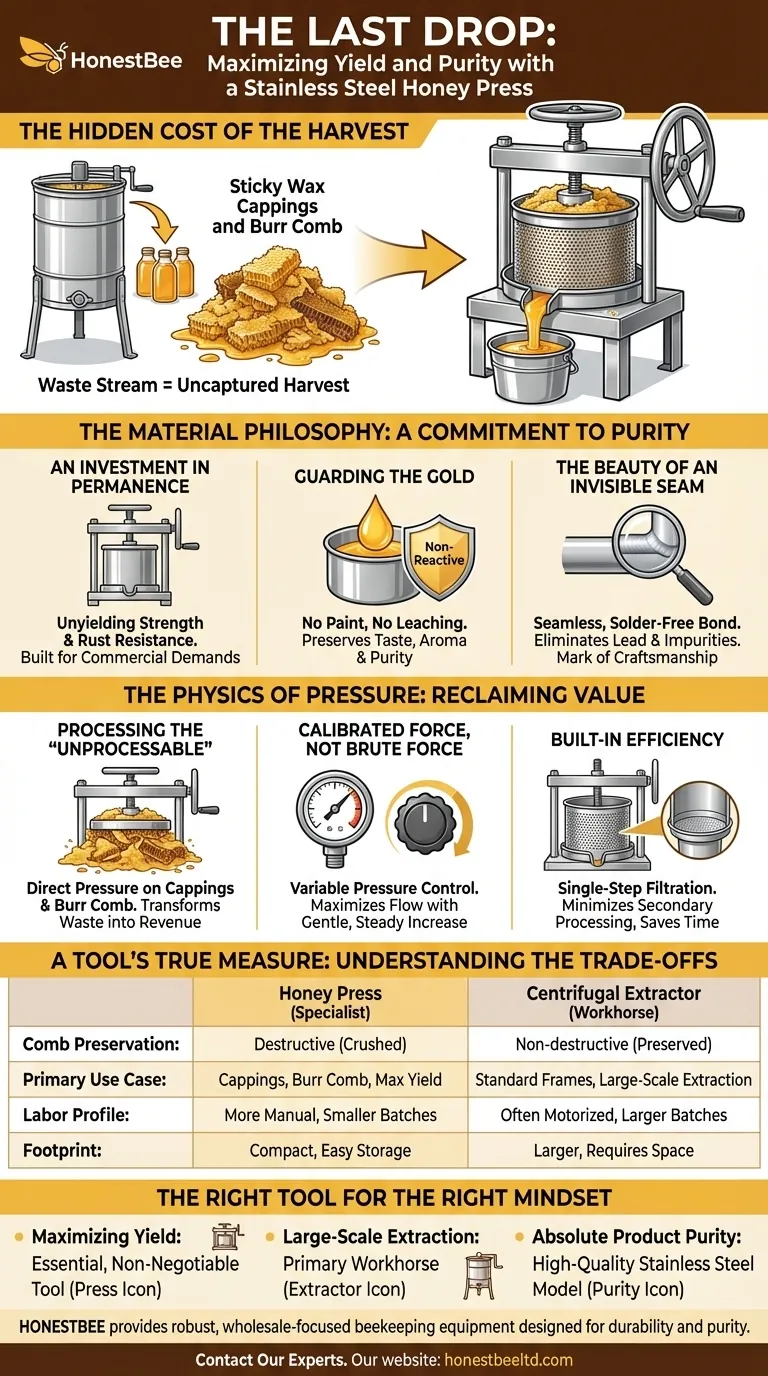

The Hidden Cost of the Harvest

After the frantic energy of extraction season, a quiet settles over the honey house. The main harvest is bottled, a testament to a year's hard work. But in the corner sits a pile of wax cappings and burr comb—sticky, heavy, and rich with honey.

To many, this is the cost of doing business. An acceptable loss.

To a commercial beekeeper, however, this pile represents something else: a hidden, uncaptured harvest. It's a systemic inefficiency where valuable product is relegated to waste. This is not a problem of effort, but a problem of equipment. A centrifugal extractor, the workhorse of the industry, cannot touch this honey.

This is where the honey press changes the entire equation. It’s not just another tool; it’s a specialized instrument designed to capture the last drop.

The Material Philosophy: A Commitment to Purity

The decision to build a tool from food-grade stainless steel is a statement of intent. It reflects a philosophy that the equipment touching your product should be as pure as the product itself.

An Investment in Permanence

A honey press operates under immense pressure. Stainless steel is not chosen for its shine, but for its unyielding strength and resistance to rust. It's a long-term investment in operational reliability, built to withstand the physical demands of a commercial apiary season after season.

Guarding the Gold

Honey is a delicate, natural product. Stainless steel is non-reactive. It has no paint to chip, no coating to degrade, and no chemicals to leach into the golden liquid it processes. It acts as an inert guardian, ensuring the honey's taste, aroma, and purity remain exactly as the bees made it.

The Beauty of an Invisible Seam

The highest quality presses feature TIG (Tungsten Inert Gas) welds. This isn't just a manufacturing detail; it's a critical safety feature. TIG welding creates a seamless, solder-free bond. Since solder can contain lead and other impurities, its absence is a non-negotiable feature for anyone serious about producing food-grade honey. It's a mark of true craftsmanship.

The Physics of Pressure: Reclaiming Value

While the material provides the foundation, the press's mechanical design is what unlocks its financial and operational value. It excels where other methods fail.

Processing the "Unprocessable"

The primary function of a press is to do what a centrifugal extractor cannot: process wax cappings, burr comb, and crushed comb. By applying direct pressure, it separates the trapped honey from the wax.

This single capability transforms a waste stream into a revenue stream, significantly increasing the total yield from every hive.

Calibrated Force, Not Brute Force

Effective extraction isn't about maximum pressure; it's about the right pressure. Variable pressure control allows the operator to adapt to the temperature and consistency of the wax.

A gentle, steady increase in force maximizes honey flow without unnecessary effort, turning a physical process into a controlled, efficient task.

Built-in Efficiency

Modern presses often integrate a filtering system, such as a perforated basket. This allows liquid honey to drain away from the compressed wax puck in a single, clean step. This design minimizes secondary processing, saving valuable time during the busiest part of the season.

A Tool’s True Measure: Understanding the Trade-offs

No tool is perfect for every job. The honey press is a specialist, and its power comes from understanding its specific role.

| Consideration | Honey Press | Centrifugal Extractor |

|---|---|---|

| Comb Preservation | Destructive (comb is crushed) | Non-destructive (comb is preserved) |

| Primary Use Case | Cappings, burr comb, maximizing yield | Standard frames, large-scale extraction |

| Labor Profile | More manual, smaller batches | Often motorized, larger batches |

| Footprint | Compact and easy to store | Larger and requires more space |

The core trade-off is comb preservation. An extractor saves the bees the energy of rebuilding wax. A press maximizes honey yield from comb that was going to be rendered anyway.

For a commercial operation, the ideal system often includes both. The extractor handles the bulk processing of frames, while the press ensures nothing is left behind.

The Right Tool for the Right Mindset

Your choice of equipment reflects your operational priorities.

- For maximizing every drop of yield, a honey press is an essential, non-negotiable tool.

- For large-scale, high-throughput extraction, a centrifugal extractor remains the primary workhorse.

- For guaranteeing absolute product purity and investing in equipment that lasts, a high-quality stainless steel model of either is the only professional choice.

Ultimately, a honey press is an investment in efficiency and quality. It’s a tool for beekeepers who understand that true value is found not just in the main harvest, but in ensuring nothing goes to waste.

For commercial apiaries and distributors committed to this level of operational excellence, HONESTBEE provides robust, wholesale-focused beekeeping equipment designed for durability and purity. Contact Our Experts

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Honey Press Wax Press with Tank

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

Related Articles

- How to Extract Honey Safely: Comb Preservation and Bee Calming Techniques

- How Honey Screw Presses Deliver Higher Yields With Less Waste

- The Physics of Patience: Mastering Honey Extractor Speed to Save Your Combs

- Beyond the Extractor: How Honey Presses Turn Waste into Profit for Commercial Apiaries

- How to Harvest Honeycombs Efficiently Without Compromising Quality or Bee Health