For small and medium-sized honey producers, balancing operational costs with product quality is a constant challenge. Honey vacuum thickeners offer a solution by streamlining processing while preserving the natural properties that make your honey stand out in competitive markets.

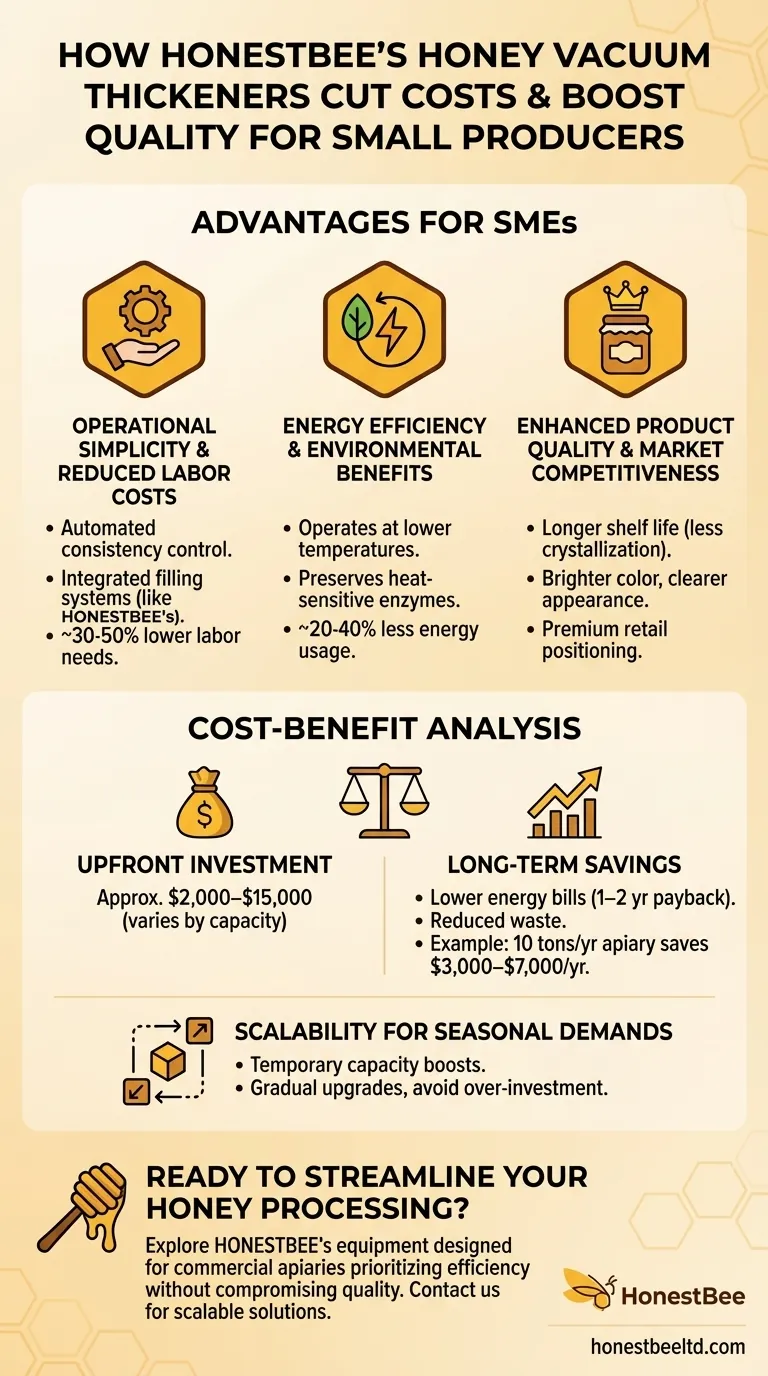

Advantages of Honey Vacuum Thickeners for SMEs

Operational Simplicity and Reduced Labor Costs

Traditional honey processing often requires multiple steps and manual oversight. Vacuum thickeners consolidate these tasks:

- Automated consistency control adjusts viscosity without constant operator intervention.

- Integrated filling systems (like those in HONESTBEE’s equipment) reduce handling steps, cutting labor needs by roughly 30–50% compared to manual methods.

This simplicity is especially valuable for seasonal producers scaling up during peak flows.

Energy Efficiency and Environmental Benefits

Unlike thermal evaporation, vacuum thickening operates at lower temperatures:

- Preserves heat-sensitive enzymes (e.g., diastase), maintaining honey’s "raw" quality claims.

- Uses ~20–40% less energy by leveraging vacuum pressure instead of sustained high heat.

Smaller carbon footprints also align with growing consumer demand for sustainable production.

Enhanced Product Quality and Market Competitiveness

- Longer shelf life: Vacuum processing minimizes moisture retention, a key factor in crystallization and spoilage.

- Brighter color and clearer appearance, critical for premium retail positioning.

"The equipment’s high efficiency makes it ideal for SMEs aiming to compete with larger brands," notes a beekeeping equipment distributor.

Cost-Benefit Analysis for Small-Scale Honey Processing

Upfront Investment vs. Long-Term Savings

While vacuum thickeners require an initial investment of approximately $2,000–$15,000 (depending on capacity), the ROI comes from:

- Lower energy bills (payback periods average 1–2 years).

- Reduced waste from consistent moisture control.

For example, a mid-sized apiary processing 10 tons annually could save $3,000–$7,000 yearly in labor and utilities.

Scalability for Seasonal Production Demands

Modular designs allow:

- Temporary capacity boosts during high-yield periods.

- Gradual upgrades as business grows, avoiding over-investment early on.

Ready to streamline your honey processing? Explore HONESTBEE’s beekeeping equipment designed for commercial apiaries and distributors who prioritize efficiency without compromising quality. Contact us to discuss scalable solutions tailored to your production volume.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

Related Articles

- Tangential vs Radial Honey Extractors: How to Choose for Your Beekeeping Needs

- How to Strain Honey Like a Pro: Science-Backed Methods for Maximum Purity

- How to Heat Honey Without Destroying Its Nutrients: Science-Backed Methods

- The Last Gate: Why a Simple Strainer Defines Honey Quality at Any Scale

- How Flow Frames Revolutionize Beekeeping with Bee-Friendly Honey Harvesting