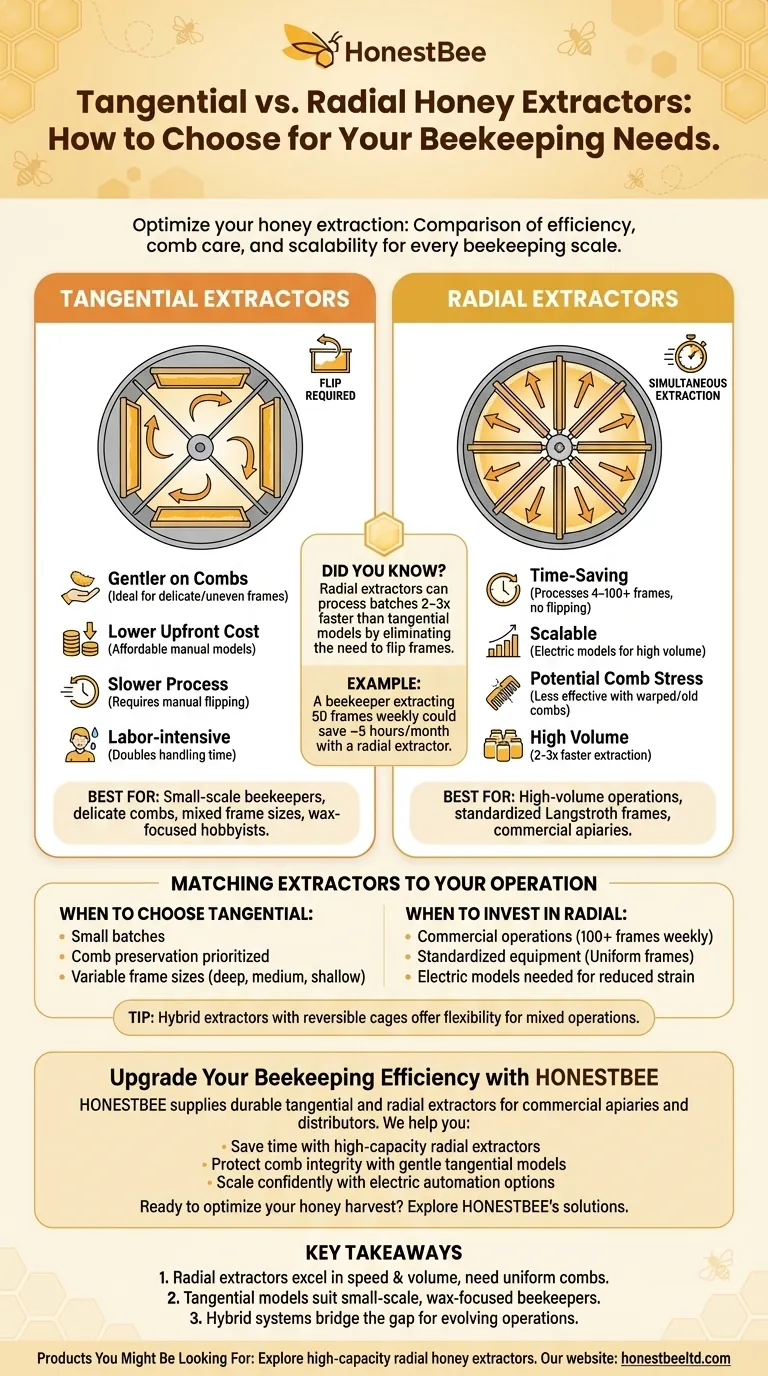

Choosing the right honey extractor can make or break your beekeeping operation. Whether you're a hobbyist managing a few hives or a commercial beekeeper processing hundreds of frames, the decision between tangential and radial extractors impacts labor efficiency, comb durability, and long-term scalability. This guide compares both types to help you optimize honey extraction for your specific needs.

How Frame Orientation Impacts Extraction Efficiency

Honey extractors use centrifugal force to remove honey while preserving combs for reuse. The key difference lies in how frames are positioned:

-

Tangential Extractors:

- Frames face outward (parallel to the drum wall)

- Extract honey from one side at a time, requiring manual flipping

- Slower process but gentler on delicate or uneven combs

-

Radial Extractors:

- Frames are arranged like spokes (perpendicular to the drum)

- Extract honey from both sides simultaneously

- Faster but may stress older or irregular combs

Did you know? Radial extractors can process batches 2–3x faster than tangential models by eliminating the need to flip frames.

Pros and Cons: Labor Time, Comb Damage, and Scalability

Tangential Extractors

Best for: Small-scale beekeepers, delicate combs, or mixed frame sizes.

- ✅ Gentler on combs: Ideal for beeswax foundations or unevenly drawn frames.

- ✅ Lower upfront cost: Manual models start at a fraction of radial extractor prices.

- ❌ Labor-intensive: Flipping frames doubles handling time per batch.

Radial Extractors

Best for: High-volume operations, standardized Langstroth frames.

- ✅ Time-saving: Processes 4–100+ frames per batch without flipping.

- ✅ Scalable: Electric models automate extraction for commercial apiaries.

- ❌ Comb compatibility: Less effective with warped or plastic-supported combs.

Example: A beekeeper extracting 50 frames weekly could save ~5 hours/month with a radial extractor.

Matching Extractors to Your Operation

When to Choose Tangential Extractors

- Small batches

- Comb preservation: Prioritized by hobbyists selling beeswax or cut-comb honey.

- Variable frame sizes: Adaptable to deep, medium, or shallow Langstroth frames.

When to Invest in Radial Extractors

- Commercial operations: Wholesale-focused apiaries processing 100+ frames weekly.

- Standardized equipment: Uniform frames maximize radial efficiency.

- Electric models: Reduce physical strain for large-scale beekeepers.

Tip: Hybrid extractors with reversible cages offer flexibility for mixed operations.

Upgrade Your Beekeeping Efficiency with HONESTBEE

Whether you're scaling up or refining your extraction process, HONESTBEE supplies durable tangential and radial honey extractors designed for commercial apiaries and distributors. Our wholesale-focused equipment helps you:

- Save time with high-capacity radial extractors

- Protect comb integrity using gentle tangential models

- Scale confidently with electric automation options

Ready to optimize your honey harvest? Explore HONESTBEE’s beekeeping solutions tailored to your operation’s size and goals.

Key Takeaways

- Radial extractors excel in speed and volume but require uniform combs.

- Tangential models suit small-scale or wax-focused beekeepers.

- Hybrid systems bridge the gap for evolving operations.

By aligning your extractor choice with comb type, labor capacity, and production scale, you’ll streamline one of beekeeping’s most critical processes—turning hive work into liquid gold.

Products You Might Be Looking For:

Explore high-capacity radial honey extractors

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

Related Articles

- Honey Press vs. Extractor: Why Your Choice Defines Your Apiary's Profitability

- How Automatic Honey Extractors Cut Costs and Boost Scalability for Commercial Beekeepers

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability