For beekeepers, the straining process is where raw honey transforms into a crystal-clear product. But common mistakes—rushing the process, using subpar materials, or ignoring environmental factors—can compromise purity and yield. Here’s how to optimize every step, whether you’re a hobbyist or a small-scale producer.

The Simple Straining Method Demystified

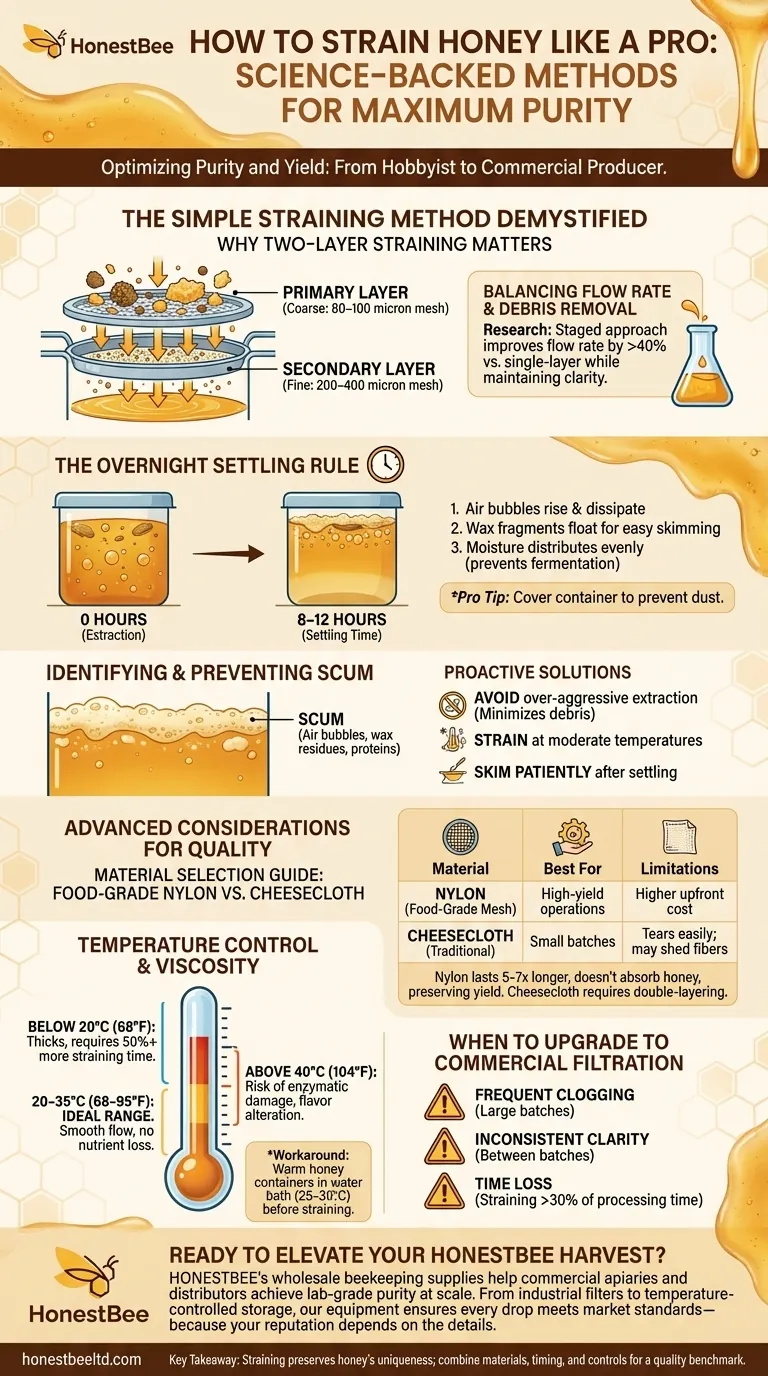

Why Two-Layer Straining Matters: Balancing Flow Rate and Debris Removal

A single filter layer often forces a trade-off: coarse mesh lets debris through, while fine mesh clogs easily. The solution? A dual-layer system:

- Primary Layer (Coarse): Catches large debris like wax chunks (80–100 micron mesh)

- Secondary Layer (Fine): Removes pollen and tiny particles (200–400 micron mesh)

Research shows this staged approach improves flow rate by over 40% compared to single-layer setups while maintaining clarity.

The Overnight Settling Rule: How Time Impacts Clarity and Moisture

Before straining, let extracted honey sit for 8–12 hours. This allows:

- Air bubbles to rise and dissipate

- Wax fragments to float to the surface for easy skimming

- Moisture to distribute evenly (critical for preventing fermentation)

Pro Tip: Cover the container during settling to prevent dust contamination.

Identifying and Preventing Scum: Causes and Proactive Solutions

That foamy layer atop your honey? It’s often a mix of air bubbles, wax residues, and proteins. To minimize it:

- Avoid over-aggressive extraction (high-speed uncapping creates more debris)

- Strain at moderate temperatures (see Advanced Considerations below)

- Skim patiently—wait until after settling for cleaner removal

Advanced Considerations for Quality-Conscious Beekeepers

Material Selection Guide: Food-Grade Nylon vs. Traditional Cheesecloth

| Material | Best For | Limitations |

|---|---|---|

| Food-grade nylon | High-yield operations | Higher upfront cost |

| Cheesecloth | Small batches | Tears easily; may shed fibers |

Nylon mesh lasts 5–7x longer and doesn’t absorb honey, preserving yield. Cheesecloth works for occasional use but requires double-layering to match nylon’s filtration.

Temperature Control: How Heat Affects Straining Efficiency

Honey’s viscosity changes dramatically with temperature:

- Below 20°C (68°F): Honey thickens, requiring 50%+ more straining time

- 20–35°C (68–95°F): Ideal range for smooth flow without nutrient loss

- Above 40°C (104°F): Risk of enzymatic damage and flavor alteration

Workaround: Warm honey containers in a water bath (not direct heat) to maintain 25–30°C before straining.

When to Upgrade: Signs You Need Commercial-Grade Filtration

Consider professional equipment if you notice:

- Frequent clogging during large batches

- Inconsistent clarity between batches

- Time loss (straining takes >30% of your processing time)

Ready to Elevate Your Honey Harvest?

HONESTBEE’s wholesale beekeeping supplies help commercial apiaries and distributors achieve lab-grade purity at scale. From industrial filters to temperature-controlled storage, our equipment ensures every drop meets market standards—because your reputation depends on the details.

Key Takeaway: Straining isn’t just about removing debris; it’s about preserving what makes your honey unique. By combining the right materials, timing, and environmental controls, you’ll turn a routine step into a quality benchmark.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How Flow Frames Revolutionize Beekeeping with Bee-Friendly Honey Harvesting

- How to Harvest Honey Naturally: A Beekeeper’s Guide to Crush & Strain

- The Last Gate: Why a Simple Strainer Defines Honey Quality at Any Scale

- How Honey Vacuum Thickeners Cut Costs Without Sacrificing Quality for Small Honey Producers

- From Chaos to Clarity: The Physics and Psychology of Honey Filtering