Beekeeping success hinges on mastering foundational elements—quite literally. Comb foundation sheets serve as the architectural blueprint for your hive, directly influencing colony health, honey production efficiency, and overall apiary management. This guide unpacks practical techniques to implement comb foundations effectively, drawing on nature’s engineering principles and proven beekeeping methods.

The Essential Role of Comb Foundations

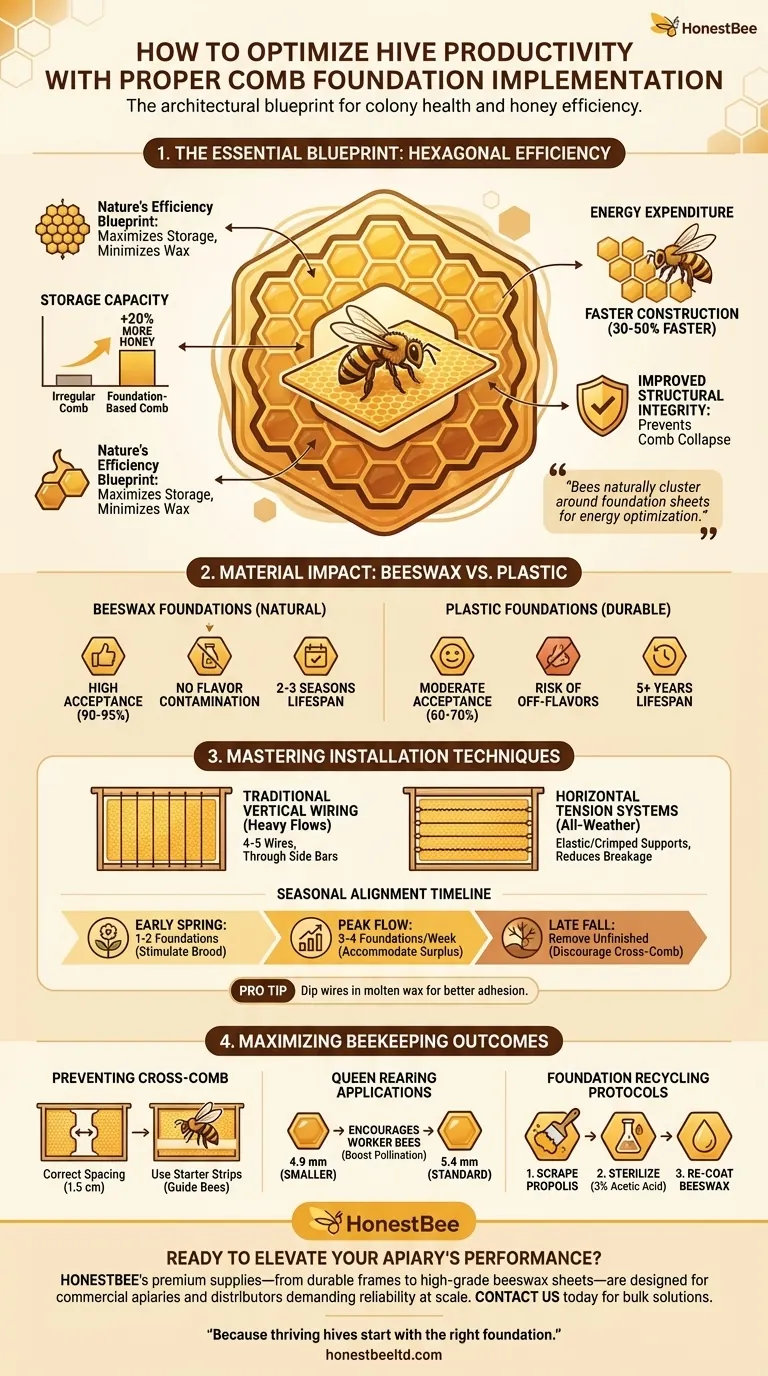

Hexagonal Engineering: Nature's Efficiency Blueprint

Honeybees instinctively build hexagonal cells—a design that maximizes storage capacity while minimizing wax usage. Research shows this geometric pattern allows colonies to store over 20% more honey compared to irregular comb structures. By using pre-embossed foundation sheets, beekeepers:

- Reduce energy expenditure: Bees complete comb construction 30–50% faster when working over foundations.

- Improve structural integrity: Uniform cell depth prevents comb collapse during honey extraction.

"Have you noticed how bees naturally cluster around foundation sheets? This isn’t just instinct—it’s energy optimization."

Wax vs. Plastic: Material Impact on Colony Health

While plastic foundations offer durability, natural wax sheets align better with colony behavior:

| Factor | Beeswax Foundations | Plastic Foundations |

|---|---|---|

| Acceptance Rate | High (90–95%) | Moderate (60–70%) |

| Honey Flavor | No reported contamination | Risk of off-flavors if unpurified |

| Lifespan | 2–3 seasons | 5+ years |

For commercial apiaries prioritizing honey purity and colony health, beeswax remains the gold standard.

Mastering Installation Techniques

Wiring Methods: Traditional vs. Modern Tension Systems

Securing foundations to frames prevents sagging. Two approaches dominate:

-

Traditional Vertical Wiring

- Uses 4–5 wires per frame, threaded through side bars.

- Best for heavy honey flows (e.g., clover or orange blossom seasons).

-

Horizontal Tension Systems

- Employs elasticized wiring or crimped metal supports.

- Reduces wire breakage during freezing temperatures.

Pro Tip: Dip wires in molten wax before installation to enhance adhesion.

Seasonal Alignment with Nectar Flows

Timing foundation installation boosts productivity:

- Early Spring: Introduce 1–2 foundations per hive to stimulate brood expansion.

- Peak Flow: Add 3–4 foundations weekly to accommodate surplus honey.

- Late Fall: Remove unfinished combs to discourage cross-combing.

Maximizing Beekeeping Outcomes

Preventing Cross-Comb Disasters

Colonies that build haphazard comb waste resources and complicate inspections. Mitigate this by:

- Spacing frames correctly: Maintain 1.5 cm between foundations.

- Using starter strips: Guide bees to build within frames.

Queen Rearing Applications

Foundations with smaller cell imprints (4.9 mm vs. standard 5.4 mm) encourage worker bee production, ideal for:

- Replenishing aging colonies.

- Boosting pollination-dependent crop yields.

Foundation Recycling Protocols

Extend your investment by:

- Scraping excess propolis gently with a hive tool.

- Sterilizing in a 3% acetic acid solution (avoid bleach).

- Re-coating with a thin beeswax layer for reuse.

Ready to Elevate Your Apiary’s Performance?

HONESTBEE’s premium beekeeping supplies—from durable foundation frames to high-grade beeswax sheets—are designed for commercial apiaries and distributors demanding reliability at scale. Contact us today to discuss bulk solutions tailored to your operation’s needs.

"Because thriving hives start with the right foundation."

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Food Grade Plastic bee Foundation for Bee Frames

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

Related Articles

- Why Your Beeswax Foundation Fails: A Guide to Preventing Costly Warping and Breakage

- Stop Blaming Your Rollers: The Real Source of Flawed Beeswax Foundation

- How to Reinforce Wax Foundations: A Beekeeper’s Guide to Wiring vs. Pre-Wired Frames

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- The Unseen Architecture: How Wax Foundation Engineers a Hive's Economy