You pull another beeswax foundation sheet from the production line. For a moment, it looks perfect. Then you see it: a thin, almost translucent patch on one side and a thick, clumsy ridge on the other. You handle it, and it cracks under the slightest pressure. It’s useless. Another one for the scrap pile.

If this scene is frustratingly familiar, you're not alone. For commercial apiaries and equipment distributors, inconsistent foundation quality is a chronic headache that seems impossible to solve.

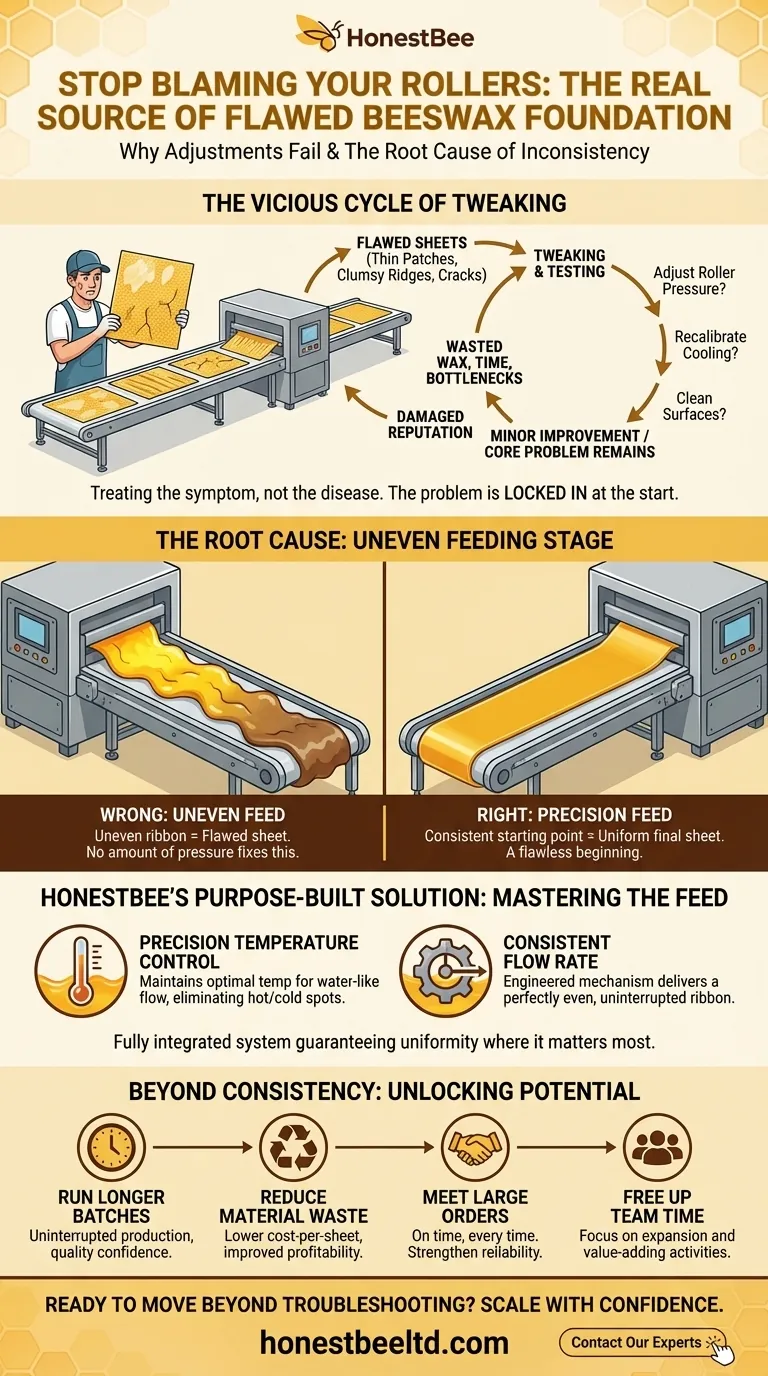

The Vicious Cycle of Tweaking and Testing

When faced with flawed sheets, the instinct is to look at the final stages of production. You start asking the usual questions:

- Are the embossing rollers calibrated correctly?

- Is the pressure too high? Or maybe too low?

- Is the cooling belt running at the right speed?

So you begin the cycle of adjustments. You tweak the roller pressure. You recalibrate the cooling system. You meticulously clean every surface. Sometimes you see a slight improvement, but the core problem of inconsistent thickness and brittleness always returns.

This isn't just an operational nuisance; it's a direct hit to your bottom line. Every failed sheet represents wasted raw beeswax, wasted operator time, and a production bottleneck that delays orders. For distributors, inconsistent quality can damage your reputation and lead to customer complaints. The costs add up, batch after frustrating batch.

The Turning Point: Why the Problem Starts Before the Press

The reason these adjustments fail is simple: you're treating the symptom, not the disease. The quality of a beeswax foundation sheet isn't determined when it's pressed; it's determined in the very first second it's formed.

The root cause of almost all sheet inconsistency is an uneven feeding stage.

Think of it like this: you can't build a straight wall with crooked bricks. Similarly, your precision rollers can only flatten and emboss the material they are given. If the initial ribbon of molten wax fed into the machine is uneven—thicker in some spots, thinner in others, or at an inconsistent temperature—no amount of pressure or post-production tweaking can magically fix it.

The "solutions" of adjusting rollers and cooling speeds fail because they attempt to correct a fundamental flaw that is already locked into the material. The sheet was doomed from the start.

Mastering the Feed: The Principle of Purpose-Built Equipment

To solve this foundational problem, you need a system designed from the ground up to master the feeding stage. It requires a machine that doesn't treat feeding as a simple "pouring" step, but as the most critical control point in the entire process.

This is the core engineering principle behind HONESTBEE's production equipment. We understand that achieving a flawless final product is impossible without first achieving a flawless beginning. Our machinery is designed as a fully integrated system to guarantee uniformity where it matters most.

Here’s how our equipment directly addresses the root cause:

- Precision Temperature Control: Our integrated melters maintain the molten beeswax at the exact optimal temperature, ensuring it flows like water, not sludge. This eliminates the hot and cold spots that lead to weak points.

- Consistent Flow Rate: The feeding mechanism is engineered to deliver a perfectly even, uninterrupted ribbon of wax onto the processing surface. This consistent starting point is the non-negotiable requirement for a uniform final sheet.

Our equipment isn't just a collection of parts; it's a purpose-built solution born from a deep understanding of the problem. It’s designed to stop the cycle of guesswork and give you absolute control over the most critical variable in your production.

Beyond Consistency: Unlocking New Production Potential

When you are no longer firefighting production flaws, your entire operational focus can shift from damage control to strategic growth. Mastering the feeding stage with the right equipment doesn't just fix a problem; it unlocks new capabilities.

You can now:

- Run longer, uninterrupted production batches with the confidence that every sheet will meet your quality standard.

- Dramatically reduce material waste, lowering your cost-per-sheet and improving profitability.

- Meet large wholesale orders on time, every time, strengthening your reputation as a reliable supplier.

- Free up your team's time to focus on expansion, maintenance, and other value-adding activities instead of constant troubleshooting.

Producing premium beeswax foundation isn't about luck or endless tweaking; it's about control, right from the very first step. This level of control is how operational excellence is built, leading to lower costs, higher output, and a stronger market position. If you're ready to move beyond constant troubleshooting and scale your operation with confidence, our team is here to help you architect the right solution for your commercial apiary or distribution business. Contact Our Experts.

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Food Grade Plastic bee Foundation for Bee Frames

Related Articles

- Chaos and Order: The Strategic Value of Beeswax Foundation

- How Beekeepers Can Choose the Right Comb Reinforcement for Hive Health and Durability

- The Unseen Architecture: How Wax Foundation Engineers a Hive's Economy

- How Beeswax Foundations Enhance Colony Health and Beekeeping Efficiency

- Is Your Plastic Foundation Costing You Honey? Why "Pre-Waxed" Might Not Be Enough