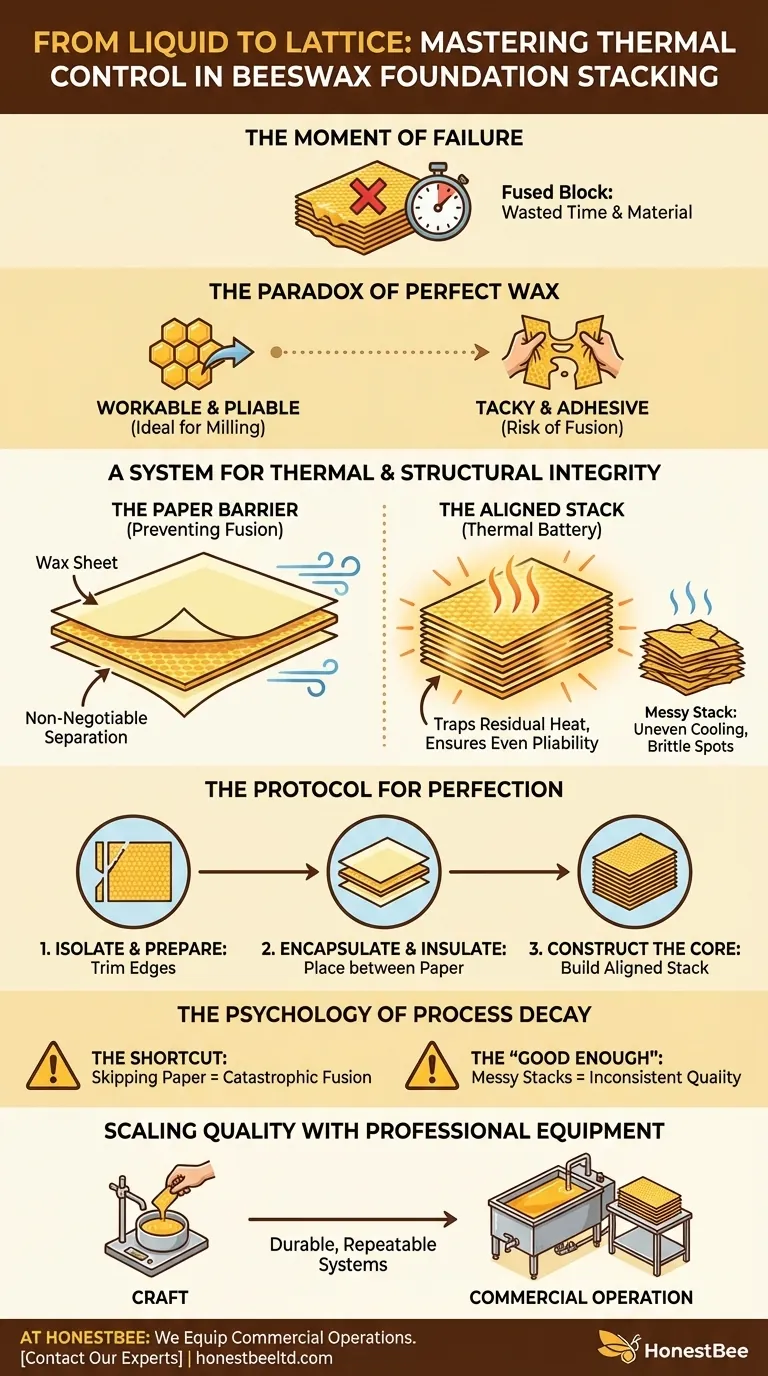

The Moment of Failure

Imagine the scene: hours spent carefully melting wax and dipping boards, resulting in dozens of perfectly formed, golden sheets. But in a rush to finish, they are piled directly on top of one another.

When you return, you don't have a stack of individual sheets. You have a single, useless block—a monument to wasted time and material.

This isn't just a simple mistake. It's a failure to understand a fundamental conflict at the heart of foundation production.

The Paradox of Perfect Wax

Freshly dipped beeswax exists in a state of perfect paradox.

It is warm, pliable, and ductile—the ideal condition for being milled or embossed with the crisp, hexagonal pattern of a honeycomb.

Simultaneously, it is tacky and adhesive. This warmth that makes it workable also makes it desperately want to fuse with any other wax surface it touches. The very property that enables quality is the same one that threatens total failure.

The process of stacking, therefore, is not about storage. It is a system designed to solve this paradox.

A System for Thermal and Structural Integrity

Proper stacking is an act of engineering. You are manipulating thermodynamics and structure to preserve the wax in its ideal state for the next step: milling. This system has two core components.

The Paper Barrier: Preventing Catastrophic Fusion

The most obvious element is the separation paper. Placed between each sheet, it acts as a simple, non-negotiable barrier.

Its function is absolute: to prevent adhesion. Without it, the warm sheets will fuse, and the batch is ruined. It is the single most critical control point in the workflow between dipping and embossing.

The Aligned Stack: A Thermal Battery

The second, more subtle element is the stack itself. A neat, perfectly aligned stack does more than look professional; it creates a thermal battery.

By minimizing the surface area exposed to the cooler ambient air, the stack traps residual heat from the dipping process. This retained warmth is distributed evenly throughout the layers, keeping the entire batch of wax pliable and ready for the mill.

A messy, haphazard pile allows heat to escape unevenly, creating cool, brittle spots that will crack or take a poor impression during embossing.

The Protocol for Perfection

The procedure is a masterclass in efficiency and control.

- Isolate and Prepare: After peeling the sheet from the dipping board, trim the edges. This creates a uniform unit, ready for the system.

- Encapsulate and Insulate: Place the trimmed sheet onto a piece of separation paper, then immediately cover it with another. The wax is now structurally and thermally insulated.

- Construct the Core: Continue layering wax and paper, focusing on creating a straight, uniform stack. You are building the thermal core that will keep your entire run at the optimal temperature.

The Psychology of Process Decay

The reasons this process fails are almost always psychological, stemming from a misunderstanding of risk and reward.

The Siren Call of the Shortcut

Skipping the separation paper is the most common failure. It’s a decision driven by a desire for speed, a belief that a small shortcut won't matter. But it's a bet against the fundamental physics of warm wax—a bet you will always lose. The result is not a minor defect; it is a catastrophic and total loss of the product.

The Cost of "Good Enough"

Creating messy stacks is a subtler error. It comes from an "it's good enough" mindset. While it won't cause the instant failure of a fused block, it degrades the system's thermal efficiency. The result is inconsistent quality—some sheets are perfect, others are brittle. This inconsistency is the enemy of any commercial-scale operation.

Scaling Quality with Professional Equipment

For a hobbyist, a single ruined batch is a frustration. For a commercial apiary or a distributor, it's a direct hit to the bottom line.

Scaling production from a craft to a reliable commercial operation requires transforming these principles into an unbreakable workflow. This means having durable, appropriately sized dipping tanks, boards, and a ready supply of pre-cut separation paper. The process must be repeatable, predictable, and efficient.

At HONESTBEE, we equip commercial beekeeping operations with the wholesale supplies needed to build these robust systems. Our focus is on providing durable, reliable equipment that turns best-practice principles into tangible, high-yield results.

For any operation looking to turn craft into consistent, high-yield production, having the right foundation is everything. Contact Our Experts

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

Related Articles

- How to Reinforce Wax Foundations: A Beekeeper’s Guide to Wiring vs. Pre-Wired Frames

- Why Your Milled Beeswax Foundations Warp—And How to Fix It for Good

- Why Your Beeswax Foundation Fails: A Guide to Preventing Costly Warping and Breakage

- Why Your In-House Beeswax Foundation is Failing Your Business—And How to Fix It

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science