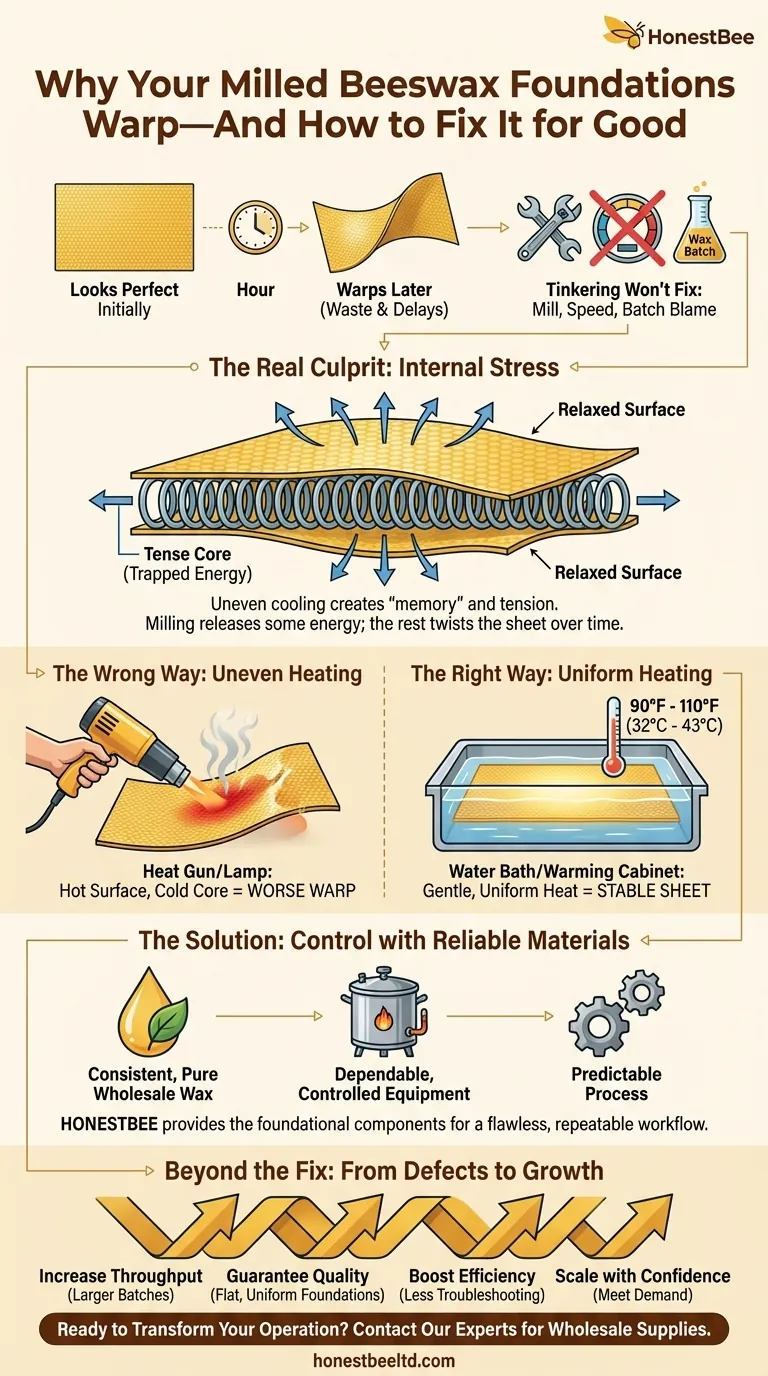

You’ve spent the morning carefully milling a batch of beeswax foundations. They look perfect—clean lines, precise cell imprints, and a smooth finish. But when you return a few hours later, you find a disaster. The sheets are warped, slightly twisted, and no longer fit properly in the frames. Another batch is wasted, and your production schedule is thrown off.

If this scenario sounds painfully familiar, you are not alone.

Why Tinkering with Your Mill Won't Fix the Problem

When faced with distorted foundations, the natural instinct is to blame the machinery. Beekeepers and equipment operators will spend countless hours:

- Recalibrating the mill, assuming an alignment issue.

- Adjusting milling speed, hoping a change will solve the problem.

- Blaming the wax batch, assuming it was a bad pour or had impurities.

While these factors can play a role, they are rarely the source of this specific, frustrating problem.

The business consequences are significant. For a commercial apiary, it means delays in preparing new hives, slowing down expansion and potentially impacting honey production. For a wholesale distributor, it means unreliable inventory, customer complaints, and damage to your reputation for quality. Each warped sheet represents not just wasted wax, but wasted time, labor, and opportunity.

The Real Culprit: Unmasking 'Internal Stress' in Your Wax

The problem isn't your mill. The distortion isn't happening during the cut. It's happening after. The true culprit is an invisible force locked within the wax itself: internal stress.

Think of a wax sheet as having a "memory." The process of creating and cooling the sheet in the first place builds up tension within its molecular structure. If you try to mill it while it's cold or unevenly heated, you are essentially carving into a tense, unstable material.

The Illusion of a Perfect Cut

When you mill a sheet with trapped internal stress, it might look perfect coming off the machine. However, the milling process itself releases some of that stored energy. Over the next few hours, as the wax settles back to room temperature, the remaining stress continues to release, pulling and twisting the material out of shape.

This is why your other fixes fail. Trying to correct this with a heat gun or a heating lamp only makes it worse. Blasting the surface with high heat creates a new, even more severe problem: the surface becomes hot and relaxed, while the core remains cool and tense. You've just created a war within the wax sheet, guaranteeing it will warp.

To get a stable, accurate result, you must gently and uniformly heat the entire sheet, from surface to core, to a stable temperature between 90°F and 110°F (32°C - 43°C). This relaxes the wax's "memory" and eliminates the internal stress before you ever make a cut.

The Solution: Control, Not Complexity

To defeat internal stress, you don't need a more complicated mill. You need a more controlled process built on a foundation of reliable materials. The goal is to apply gentle, consistent heat, and the most reliable ways to do this are with a thermostat-controlled water bath or a dedicated warming cabinet (hot box).

This is where the quality of your supplies becomes paramount. A predictable process requires predictable materials.

Building a Reliable Process with the Right Supplies

At HONESTBEE, we understand that commercial-scale success is built on repeatability. As a wholesale supplier to apiaries and distributors, our focus is on providing the foundational components for a flawless workflow.

Our wholesale beeswax is selected for its purity and consistency, ensuring you aren't fighting hidden variables in your raw materials. Our equipment, from tanks to heating elements, is designed for the rigorous demands of commercial use. This isn't about a single "magic" product; it's about providing the robust, dependable supplies that empower you to implement the correct technique perfectly, every single time. Our products are the building blocks of the control and consistency you need to eliminate warping for good.

Beyond the Fix: From Fighting Defects to Fueling Growth

Once you stop fighting post-milling distortion, your entire operation transforms. This isn't just about saving a few sheets of wax; it's about unlocking new potential.

- Increase Throughput: Run larger production batches with the confidence that they won't be rejected hours later.

- Guarantee Quality: Deliver perfectly flat, uniform foundations to your customers or for your own hives, reinforcing your reputation for precision.

- Boost Efficiency: Your team can stop wasting time on troubleshooting and re-milling, and focus on higher-value tasks like hive management, order fulfillment, or business development.

- Scale with Confidence: Whether you're expanding your apiary or growing your distribution network, you can trust your production process to keep up with demand without sacrificing quality.

Solving the wax warping issue is more than a technical fix; it's a strategic upgrade to your entire operation. It translates to higher throughput, lower costs, and a more reliable product. If you're ready to move past unpredictable results and build a more efficient, profitable beekeeping enterprise, our team is here to help. We can advise on the best wholesale supplies and equipment to match your specific needs and scale. Contact Our Experts to discuss your project and see how a foundation of quality can transform your work.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

Related Articles

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- Stop Blaming Your Rollers: The Real Source of Flawed Beeswax Foundation

- Why Your Beeswax Foundation Fails: A Guide to Preventing Costly Warping and Breakage

- The Unseen Architecture: How Wax Foundation Engineers a Hive's Economy

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science