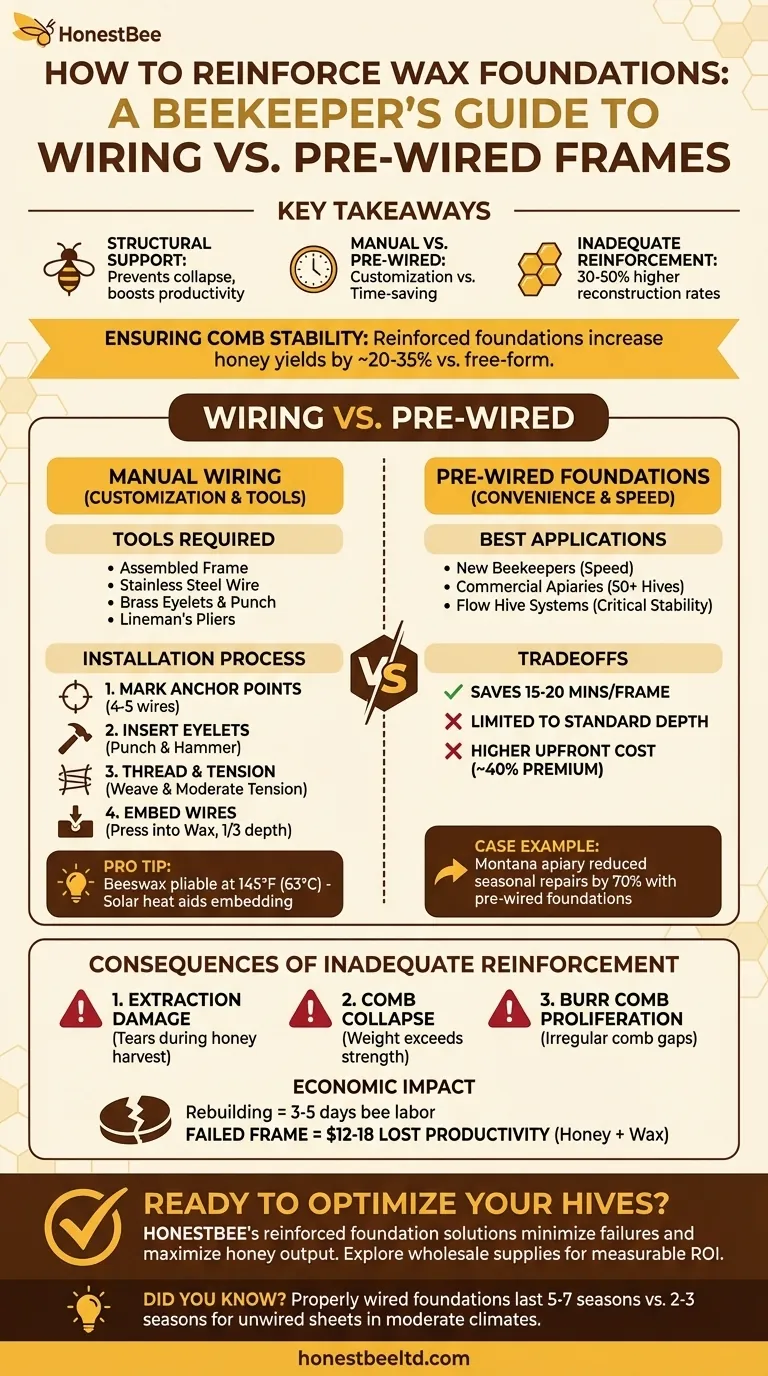

Key Takeaways:

- Structural support prevents comb collapse and boosts hive productivity

- Manual wiring offers customization but requires specialized tools

- Pre-wired foundations save time but may limit flexibility

- Inadequate reinforcement leads to 30-50% higher comb reconstruction rates

Ensuring Comb Stability in Beekeeping

Bees naturally build comb without human intervention, but modern beekeeping relies on wax foundations to optimize hive space and honey production. Research shows reinforced foundations increase honey yields by approximately 20-35% compared to free-form comb construction.

The Critical Role of Structural Support

Wax foundations serve three essential functions:

- Comb Guidance: Provides starter cells for uniform honeycomb construction

- Hive Efficiency: Reduces energy bees expend on comb building

- Disease Control: Allows easier replacement of contaminated comb sections

Unsupported wax becomes vulnerable to:

- Warping in temperatures above 85°F (29°C)

- Collapse during honey extraction

- Drone comb proliferation in brood chambers

Step-by-Step Guide to Wiring Frames

Tools Required (Based on HONESTBEE Equipment Lists):

- Assembled wooden frame

- Stainless steel frame wire

- Brass eyelets (100/pkg typically covers 25 frames)

- Eyelet punch tool

- Lineman’s pliers for tensioning

Installation Process:

-

Mark Anchor Points:

- Space 4-5 horizontal wires 1.5" apart (vertical wiring also possible)

-

Insert Eyelets:

- Punch holes at marked locations

- Set eyelets using hammer strikes

-

Thread & Tension Wires:

- Weave wire through opposing eyelets

- Apply moderate tension with pliers (over-tightening cracks wax)

-

Embed Wires:

- Press wires into wax using a spur embedder or hive tool

- Ideal depth: 1/3 into foundation thickness

Pro Tip: Beeswax becomes pliable at 145°F (63°C)—brief solar heating aids wire embedding.

Pre-Wired Foundations: When to Choose Convenience

Best Applications:

- New beekeepers prioritizing setup speed

- Commercial apiaries processing 50+ hives seasonally

- Flow hive systems where comb stability is critical

Tradeoffs:

✓ Saves 15-20 minutes per frame vs. manual wiring

✗ Limited to standard 8.5" depth frames

✗ Higher upfront cost (approximately 40% premium)

Case Example: A Montana apiary reduced seasonal comb repairs by 70% after switching to pre-wired foundations during their 300-hive expansion.

Consequences of Inadequate Reinforcement

Common Failure Scenarios:

-

Extraction Damage:

- Centrifugal force tears unsupported comb during honey harvest

-

Comb Collapse:

- Weight of capped honey exceeds wax tensile strength

-

Burr Comb Proliferation:

- Bees fill gaps with irregular comb, complicating inspections

Economic Impact:

- Rebuilding collapsed comb consumes 3-5 days of bee labor

- Each failed frame represents $12-18 in lost productivity (honey + wax)

Ready to Optimize Your Hives?

HONESTBEE’s reinforced foundation solutions help commercial beekeepers and distributors minimize comb failures while maximizing honey output. Explore our wholesale beekeeping supplies designed for high-volume operations—where every frame’s stability translates to measurable ROI.

Did You Know? Properly wired foundations last 5-7 seasons versus 2-3 seasons for unwired sheets when maintained in moderate climates.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Food Grade Plastic bee Foundation for Bee Frames

Related Articles

- The Unseen Architecture: How Wax Foundation Engineers a Hive's Economy

- Stop Blaming Your Rollers: The Real Source of Flawed Beeswax Foundation

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- How Preserving Wax Foundations Can Increase Honey Production by Over 20%

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science