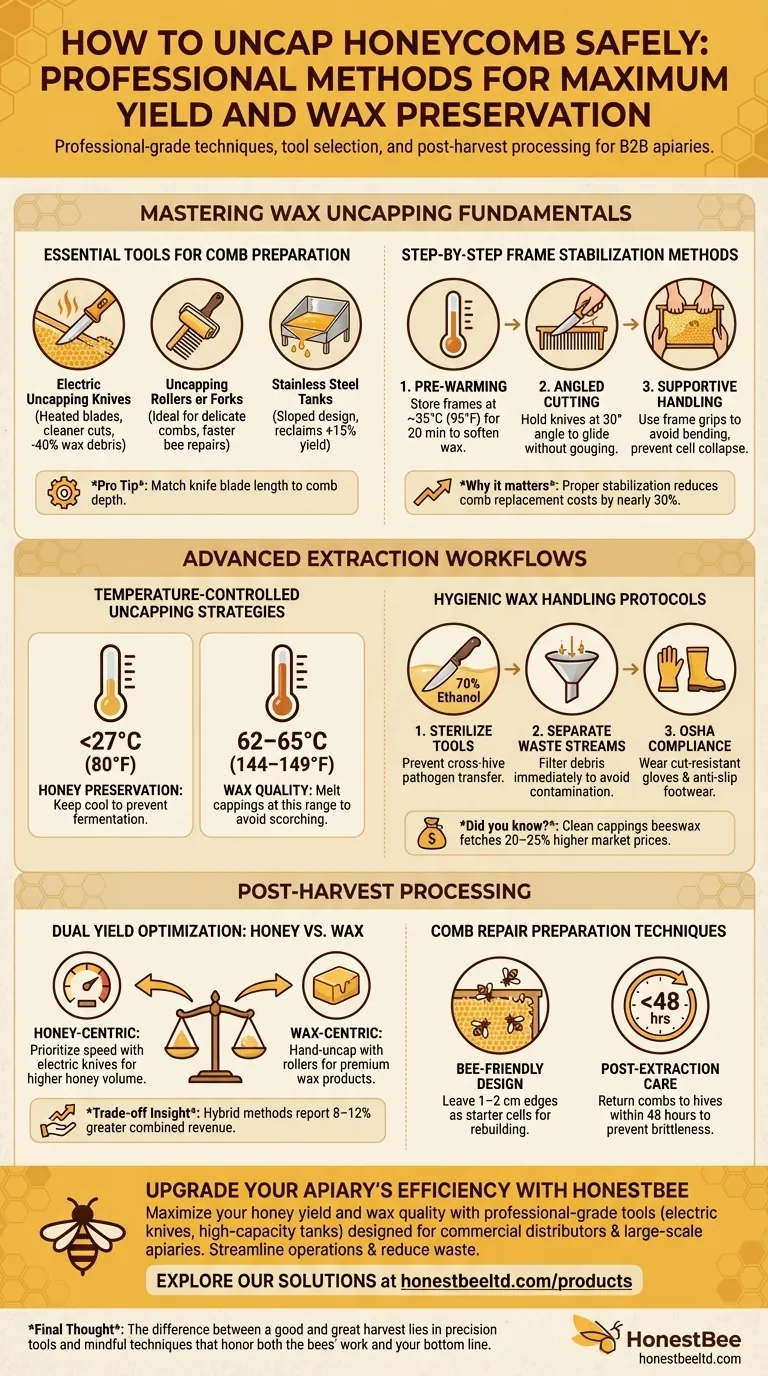

For beekeepers, uncapping honeycomb is a critical step that directly impacts honey quality, wax recovery, and comb longevity. Whether you're managing a few hives or a commercial apiary, mastering efficient wax uncapping techniques ensures you extract every drop of honey while preserving comb integrity. This guide covers professional-grade methods, from tool selection to post-harvest processing, tailored for beekeepers prioritizing both yield and sustainability.

Mastering Wax Uncapping Fundamentals

Essential Tools for Comb Preparation

The right tools minimize comb damage and labor time:

- Electric Uncapping Knives: Heated blades slice through wax seamlessly, leaving cleaner cuts than manual knives. Research shows they reduce wax debris by over 40%, streamlining filtration.

- Uncapping Rollers or Forks: Ideal for delicate combs or partial uncapping, these tools preserve cell structures for faster bee repairs.

- Stainless Steel Tanks: A sloped uncapping tank collects honey drippings efficiently, reclaiming up to 15% more yield from cappings.

Pro Tip: Match your knife’s blade length to your comb depth—standard tools often misfit deep Langstroth frames.

Step-by-Step Frame Stabilization Methods

- Pre-Warming: Store frames at ~35°C (95°F) for 20 minutes to soften wax. Cold combs fracture easily.

- Angled Cutting: Hold electric knives at a 30° angle to glide through cappings without gouging comb bases.

- Supportive Handling: Use frame grips to avoid bending mid-process, which can collapse cells.

Why it matters: A study of commercial apiaries found proper stabilization reduces comb replacement costs by nearly 30%.

Advanced Extraction Workflows

Temperature-Controlled Uncapping Strategies

- Honey Preservation: Keep workspace temperatures below 27°C (80°F) to prevent fermentation. Warmer environments accelerate yeast growth.

- Wax Quality: Melt cappings at 62–65°C (144–149°F) to avoid scorching, which degrades wax purity for resale.

Hygienic Wax Handling Protocols

- Sterilize Tools: Dip knives in 70% ethanol between frames to prevent cross-hive pathogen transfer.

- Separate Waste Streams: Filter wax debris immediately to avoid contaminating extracted honey.

- OSHA Compliance: Wear cut-resistant gloves and anti-slip footwear—extraction rooms often have slick surfaces.

Did you know? Beeswax from clean cappings fetches 20–25% higher market prices than contaminated batches.

Post-Harvest Processing

Dual Yield Optimization: Honey vs. Wax

- Honey-Centric Approach: Prioritize speed with electric knives, sacrificing some wax quality for higher honey volume.

- Wax-Centric Approach: Hand-uncap with rollers to yield intact cappings for premium wax products like cosmetics.

Trade-off Insight: Commercial apiaries using hybrid methods report 8–12% greater combined revenue from both products.

Comb Repair Preparation Techniques

- Bee-Friendly Design: Leave uncapped honey edges (1–2 cm) to give bees starter cells for rebuilding.

- Post-Extraction Care: Return combs to hives within 48 hours—prolonged drying makes them brittle.

Upgrade Your Apiary’s Efficiency with HONESTBEE

Maximize your honey yield and wax quality with professional-grade uncapping tools designed for commercial beekeepers. HONESTBEE’s wholesale-focused equipment—from precision electric knives to high-capacity tanks—helps distributors and large-scale apiaries streamline operations while reducing waste. Explore our solutions to elevate your harvests.

Final Thought: The difference between a good harvest and a great one often lies in the uncapping process—a blend of precision tools and mindful techniques that honor both the bees’ work and your bottom line.

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

- Stainless Steel Dual Blade Uncapping Plane

- Professional Compact Multi-Function Uncapping Knife for Beekeeping

- Professional Bent Tine Honey Uncapping Fork with Ergonomic Grip

Related Articles

- How to Master Essential Beekeeping Tools Safely and Efficiently

- Precision Over Pace: The Economic Logic of the Uncapping Fork

- The Mill and the Scraper: Why Patience is a Beekeeper's Most Valuable Tool

- Comprehensive Guide to Uncapping Honey Frames for Beekeepers

- How to Choose the Right Beeswax Uncapping Tool for Your Beekeeping Needs