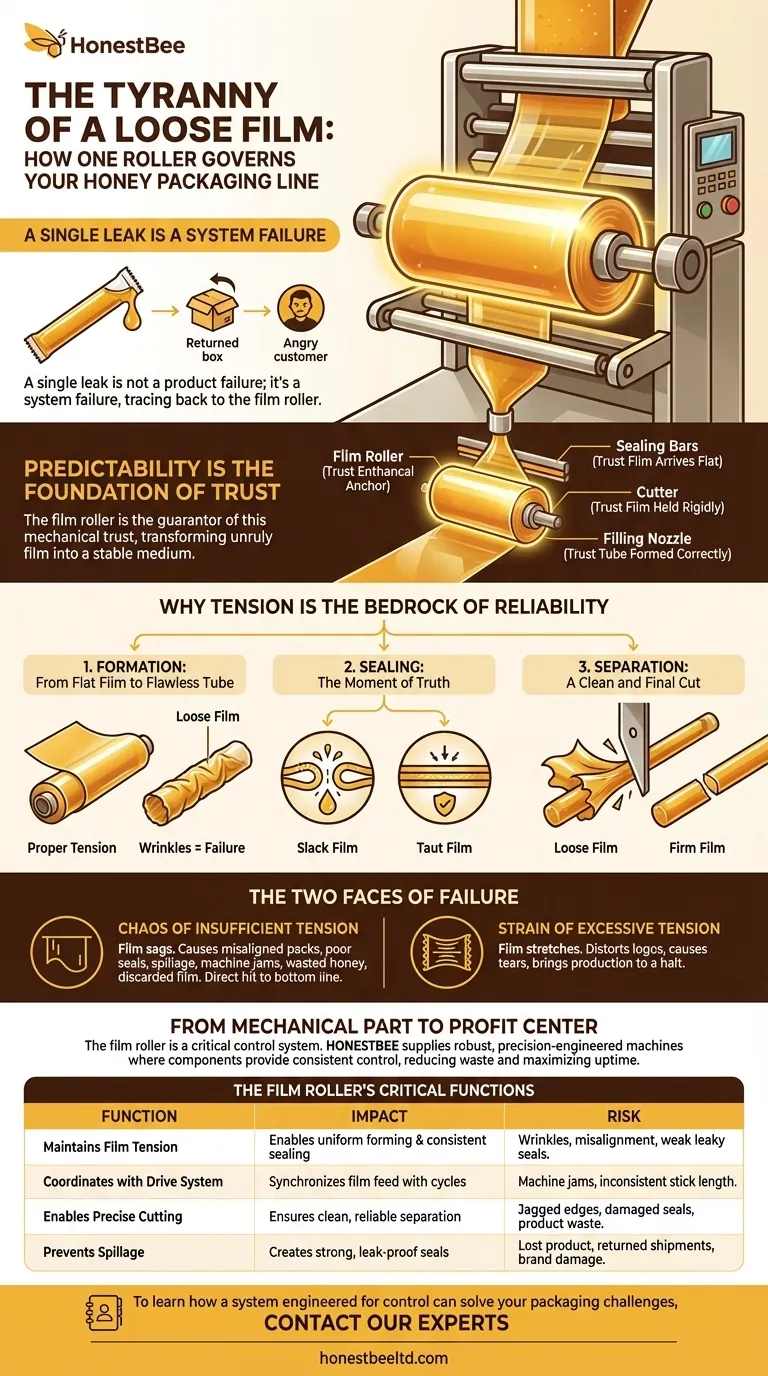

A Single Leak is a System Failure

It starts with a single drop of honey. A sticky spot on a shipping carton, a returned box from a distributor, a customer complaint.

It seems like a small defect—one faulty seal out of thousands. But it’s not a product failure; it’s a system failure. That single leak is a symptom of a deeper problem, one that traces back to a fundamental force inside your honey stick machine: tension.

The entire, complex choreography of forming, filling, sealing, and cutting a honey stick is predicated on one component doing its job perfectly. That component is the film roller. Its function isn't just to guide the film; its function is to impose absolute, predictable control.

Predictability is the Foundation of Trust

A honey stick machine is a system built on mechanical trust. The sealing bars trust that the film will arrive flat and taut. The cutter trusts the film will be held rigidly in place. The filling nozzle trusts the tube will be formed correctly.

The film roller is the guarantor of this trust.

By maintaining constant and precise tension, it transforms a flimsy, unruly roll of packaging film into a predictable, stable medium. Without this control, the system's trust breaks down. Chaos—in the form of wrinkles, misalignments, and jams—is introduced, and the entire production line becomes unreliable.

Why Tension is the Bedrock of Reliability

The roller's role can be broken down into three critical moments where tension dictates success or failure.

1. Formation: From Flat Film to Flawless Tube

Before a stick can be filled, the flat packaging film must be wrapped around a forming tube. If the film is loose, it will wrinkle and drift. A wrinkled tube cannot be sealed properly. It’s a guaranteed point of failure before any honey is even introduced. Proper tension ensures the film is perfectly smooth as it takes its new shape.

2. Sealing: The Moment of Truth

Sealing bars apply heat and pressure to fuse the film's edges. This process requires a perfectly flat, taut surface to create a uniform, hermetic seal.

- Slack film creates gaps and channels, resulting in weak points or incomplete seals. This is the direct cause of leaks.

- Taut film ensures the sealing bars apply even pressure across the entire surface, creating a strong, dependable bond that protects your product.

3. Separation: A Clean and Final Cut

After a stick is filled and sealed, a blade slices it from the continuous film strip. The film roller holds the strip firm, allowing the cutter to make a clean, precise separation. A loose film will bunch up or tear, creating jagged edges and potentially compromising the seal of the next stick in line.

The Two Faces of Failure

Control is a matter of balance. Any deviation from the optimal tension introduces immediate, costly problems.

The Chaos of Insufficient Tension

This is the most common failure. When tension is too low, the film sags. This is the root cause of misaligned packs, poor seals, and product spillage. It is the primary reason for machine jams, wasted honey, and discarded packaging film—direct hits to your bottom line.

The Strain of Excessive Tension

While less frequent, too much tension is equally destructive. It can stretch the packaging film, distorting logos and branding. In more extreme cases, it can cause the film to tear, bringing the entire production line to an abrupt halt.

From Mechanical Part to Profit Center

Thinking of the film roller as a simple part is a costly mistake. It is a critical control system—the brainstem of your packaging line, managing the flow of its most essential material.

The reliability of this system isn't just about one component; it's about how the entire machine is engineered for precision. This is why commercial apiaries and distributors rely on equipment built for industrial demands. HONESTBEE supplies robust, precision-engineered honey stick machines where components like the film roller are designed to provide consistent, reliable control, day after day.

A high-quality machine minimizes the variables. It turns the art of managing film tension into a science, reducing waste, maximizing uptime, and protecting the quality and reputation of your brand.

Summary: The Film Roller's Critical Functions

| Function | Impact on Operation | Risk if Malfunctioning |

|---|---|---|

| Maintains Film Tension | Enables uniform forming and consistent sealing | Wrinkles, misalignment, and weak, leaky seals. |

| Coordinates with Drive System | Synchronizes film feed with filling/sealing cycles | Machine jams and inconsistent stick length. |

| Enables Precise Cutting | Ensures clean, reliable separation of each stick | Jagged edges, damaged seals, and product waste. |

| Prevents Spillage | Creates strong, leak-proof seals to contain product | Lost product, returned shipments, and brand damage. |

The difference between a smooth, profitable operation and a constant battle against waste and downtime can be found in the precision of your equipment. To learn how a system engineered for control can solve your packaging challenges, Contact Our Experts.

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- Automatic Continuous Heat Sealing Machine

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

Related Articles

- How to Uncap Honeycomb Safely: Professional Methods for Maximum Yield and Wax Preservation

- Precision Over Pace: The Economic Logic of the Uncapping Fork

- How to Uncap Wax Like a Pro: Maximizing Honey Yield While Protecting Your Combs

- How to Master Essential Beekeeping Tools Safely and Efficiently

- Comprehensive Guide to Uncapping Honey Frames for Beekeepers