The Allure of Speed and Its Hidden Cost

In any production environment, the impulse is to maximize speed. Faster means more output, greater efficiency, and higher profits. We apply this logic to almost everything.

But in the world of honey extraction, this intuition is a trap.

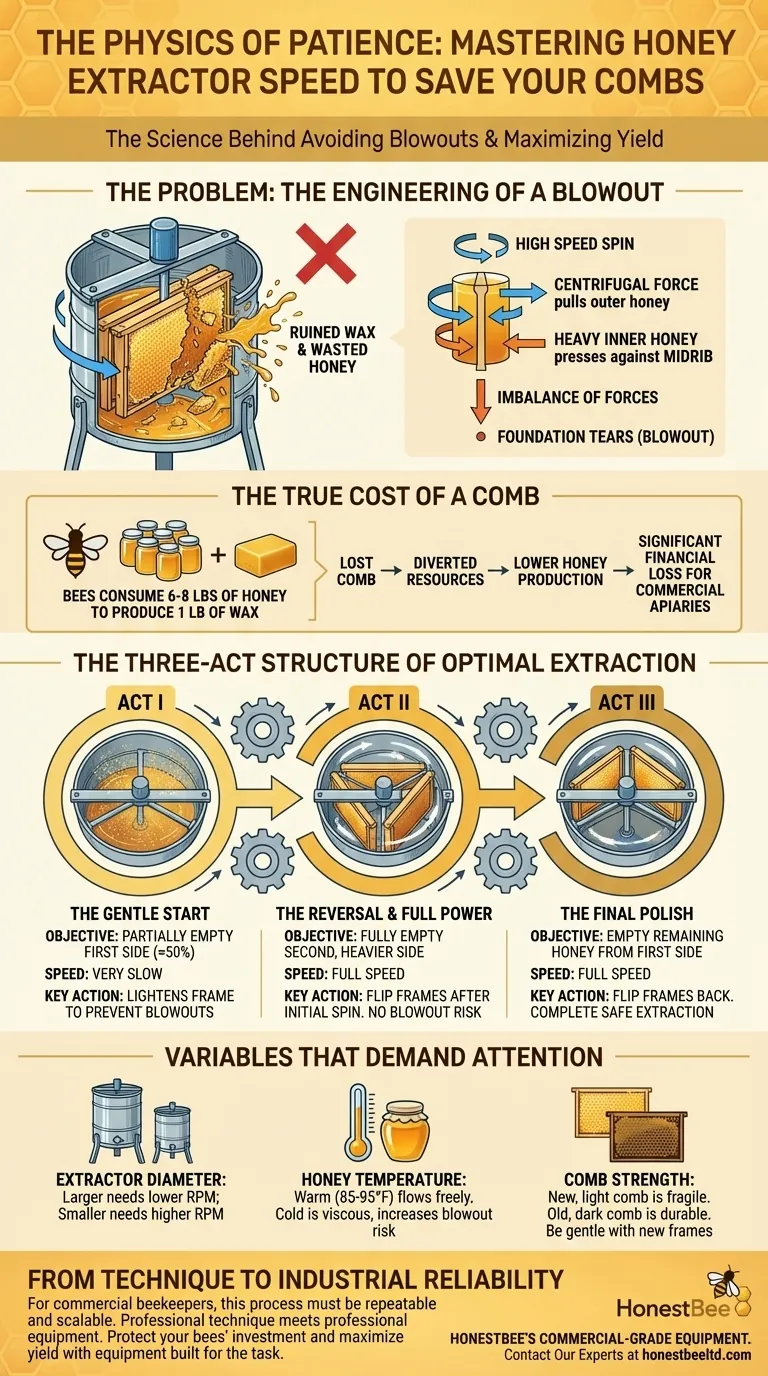

The sound of a "blowout" is unmistakable—a sickening tear as a perfect, heavy frame of honeycomb rips itself apart inside the extractor. What was once a masterpiece of bee engineering becomes a mess of ruined wax and wasted honey. The pursuit of speed, in this case, leads directly to destruction.

This isn't just a failure of equipment; it's a failure to understand the physics of a fragile system.

The Engineering of a Blowout

A full frame of honey is deceptively heavy. The delicate wax comb, while an architectural marvel, is strongest only at its foundation. When you start an extractor at high speed, you create a powerful imbalance of forces.

An Unseen Pressure

Centrifugal force pulls honey out from the cells on the outer side of the frame. That part works as intended.

The problem is the honey still trapped on the inner side. Its mass is now being pressed with immense force against the delicate midrib of the comb. If the weight is too great, the wax foundation tears away. The structure fails catastrophically.

The True Cost of a Comb

A destroyed comb is more than just a momentary setback. For a colony of bees, producing wax is one of the most energy-intensive tasks they perform. It is estimated that bees consume 6-8 pounds of honey to produce just one pound of wax.

Losing drawn comb means your bees must divert resources from honey production to rebuilding. For a commercial apiary, this is a direct and significant loss of productivity. The goal, therefore, is not just to extract honey, but to preserve this invaluable investment.

The Three-Act Structure of Optimal Extraction

The solution is not to avoid speed, but to apply it intelligently. The process is a gradual, three-step technique designed to lighten the load before applying maximum force.

Act I: The Gentle Start

Your first spin must be slow. The objective is not to empty the frame, but to remove about half the honey from the first side.

How slow? Just fast enough to see a fine spray of honey hitting the extractor wall. This initial step gently reduces the frame's total weight, relieving the pressure on the foundation.

Act II: The Reversal and Full Power

Next, you flip the frames. The partially emptied side now faces inward, and the full, heavy side faces out.

Now you can apply full speed. With the opposing side lightened, there is no risk of a blowout. The centrifugal force can now work efficiently, pulling all the honey from this second side.

Act III: The Final Polish

Finally, flip the frames back to their original position. The first side, still holding about half its honey, is once again facing out.

You can now run the extractor at full speed one last time, safely removing the remaining honey. This methodical approach protects the comb while achieving complete extraction.

| Step | Objective | Speed | Key Action |

|---|---|---|---|

| 1. Initial | Partially empty first side (≈50%) | Very Slow | Lightens the frame to prevent blowouts |

| 2. Reverse | Fully empty the second, heavier side | Full Speed | Flip frames after the initial spin |

| 3. Final | Empty the remaining honey from first side | Full Speed | Flip frames back to their original position |

Variables That Demand Your Attention

"Slow" and "fast" are relative. Mastering this technique requires adjusting for key variables:

- Extractor Diameter: A larger extractor generates more force at a lower RPM. A small 2-frame unit needs to spin much faster than a commercial 30-frame machine to achieve the same effect.

- Honey Temperature: Warm honey flows freely. Cold honey is viscous and requires significantly more force, dramatically increasing blowout risk. Warming your honey supers to 85-95°F (29-35°C) is not a luxury; it's a process requirement.

- Comb Strength: New, light-colored comb is exceptionally fragile. Older, darker comb, reinforced by generations of brood, is far more durable. You must be gentler with your new frames.

From Technique to Industrial Reliability

For a commercial beekeeper or distributor, this process must be repeatable, reliable, and scalable. A single blowout is an annoyance; systemic blowouts across an entire operation are a financial disaster. This is where professional technique meets professional equipment.

Your extractor must provide the control for a gentle start and the robust construction to handle full-speed runs with heavy loads, day after day. This is the principle behind HONESTBEE's commercial-grade equipment. We supply wholesale extractors and beekeeping supplies built for the realities of high-volume apiaries, where preserving comb is as critical as harvesting honey. Our solutions are designed to make the optimal process your standard process.

To protect your bees' investment and maximize your yield with equipment built for the task, Contact Our Experts.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

Related Articles

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- The Manual Flip: Understanding the Hidden Costs of Your First Honey Extractor

- How to Ethically Harvest Honey Without Compromising Bee Colony Survival

- How to Harvest Honey from Langstroth Hives Without Damaging Combs

- Ethical Honey Harvesting: Essential Tools and Techniques for Beekeepers