It's a familiar scene at the end of a long day of extraction: your main run is finished, the extractor is quiet, but several heavy, sticky buckets of wax cappings and burr comb remain. You know they're laden with honey, but dealing with them is a messy, inefficient chore. This leftover material often represents the most frustrating part of the harvest—a final hurdle that feels more like cleanup than production. For many commercial operations, this is simply the accepted cost of doing business. But what if it isn't?

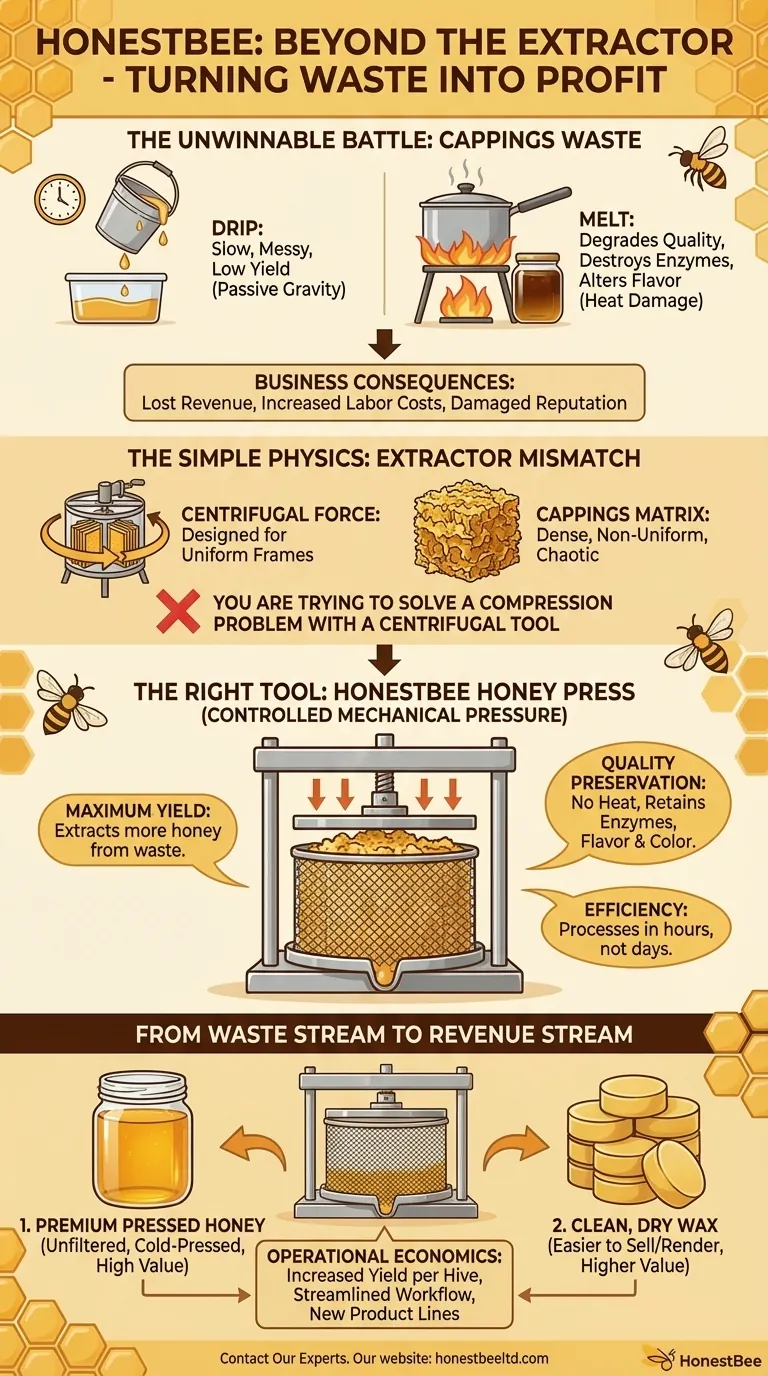

The Unwinnable Battle: Drip, Melt, or Lose

The challenge of processing cappings is universal. Faced with this sticky mixture, most apiaries resort to a few common, yet flawed, strategies.

The most popular method is passive dripping—letting gravity do the work over several days. This ties up equipment and space, and its effectiveness is minimal, leaving a significant amount of honey trapped in the wax. The result is a slow, messy process for a low yield.

Another approach is to apply heat, melting the wax to release the honey. While faster, this method introduces a far greater problem: it degrades the honey. Heat destroys the delicate enzymes and volatile aromatics that define high-quality honey, often darkening its color and altering its flavor. You recover the honey, but you sacrifice its premium value.

The business consequences of these compromises are significant. Every kilogram of honey left in the cappings is direct revenue lost. Every hour spent on inefficient processing increases labor costs. And selling heat-damaged honey at a discount erodes your brand's reputation for quality. You're caught in a frustrating loop: waste time, waste product, or compromise quality.

The Simple Physics Your Extractor Can't Handle

The reason these methods fail isn't due to a lack of effort; it's a matter of physics. The problem is a fundamental mismatch between the tool and the task.

Your centrifugal extractor is a brilliant piece of engineering designed for one job: using centrifugal force to sling liquid honey out of the uniform, open cells of a frame. It is highly effective for this specific purpose.

However, cappings and burr comb are not uniform frames. They are a dense, chaotic matrix of wax and honey. Centrifugal force is simply ineffective at separating the liquid from this solid mass. It’s like trying to use a fan to dry a soaked sponge—you’ll only affect the surface.

This is the root cause of the problem: You are trying to solve a compression problem with a centrifugal tool.

- Dripping relies on gravity, a force too weak to overcome the honey’s viscosity and surface tension within the wax matrix.

- Melting uses thermal energy, a blunt instrument that damages the product you’re trying to save.

To efficiently and safely separate the honey from the wax, you need a different kind of force altogether: controlled, mechanical pressure.

The Right Tool for the Job: Unlocking Trapped Honey with Pressure

To solve a problem of compression, you need a tool built for compression. This is where the honey press transitions from a niche piece of equipment to an essential component of a modern, profit-focused apiary.

A honey press is purpose-built to apply immense, direct pressure. It doesn’t sling, heat, or wait. It squeezes. This simple, powerful action is precisely what's needed to force the liquid honey out of the solid wax matrix without damaging its quality.

Our honey presses at HONESTBEE are engineered to address this exact challenge:

- Maximum Yield: The press applies consistent, powerful force that extracts far more honey from cappings and burr comb than any other method, directly converting what was once considered "waste" into pure profit.

- Quality Preservation: Because the entire process is mechanical and heat-free, the honey retains all its natural enzymes, flavor profiles, and light color. You can sell this pressed honey as a premium, artisanal product.

- Efficiency: What once took days of passive dripping can now be processed in a matter of hours, freeing up your team and your space for more productive tasks.

It isn't just another tool; it’s the correct physical solution to a problem that costs your operation money every season.

From Waste Stream to Revenue Stream: The New Economics of Your Apiary

Once you solve the cappings problem, you don't just reduce waste—you unlock entirely new opportunities for your business. Integrating a honey press into your workflow fundamentally changes your operational economics.

You are no longer just recovering a loss; you are creating two distinct, high-value product streams from a single source:

- Premium Pressed Honey: This unfiltered, cold-pressed honey can be marketed to discerning customers at a higher price point, celebrated for its robust flavor and natural qualities.

- Clean, Dry Wax: The press outputs compact, dry pucks of beeswax. This clean wax is far more valuable and easier to sell or render than sticky, honey-soaked cappings.

For a commercial apiary, this means a measurable increase in overall yield per hive. For a distributor, it provides a compelling, profit-driven story for your customers. It's about transforming a costly operational bottleneck into a streamlined, revenue-generating center.

Your operation is too sophisticated to be leaving valuable product on the floor. It's time to move beyond the limitations of your extractor and capture the full value of your harvest. Let's discuss how the right equipment can turn your biggest frustration into your next premium product line. Contact Our Experts.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- Stainless Steel Honey Press Wax Press with Tank

Related Articles

- Optimizing Honey Production: How to Choose the Right Stainless Steel Screw Pump Capacity

- How Honey Screw Presses Deliver Higher Yields With Less Waste

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- The Physics of Patience: Mastering Honey Extractor Speed to Save Your Combs

- The Beekeeper's Dilemma: The Brutal, Beautiful Logic of the Honey Press