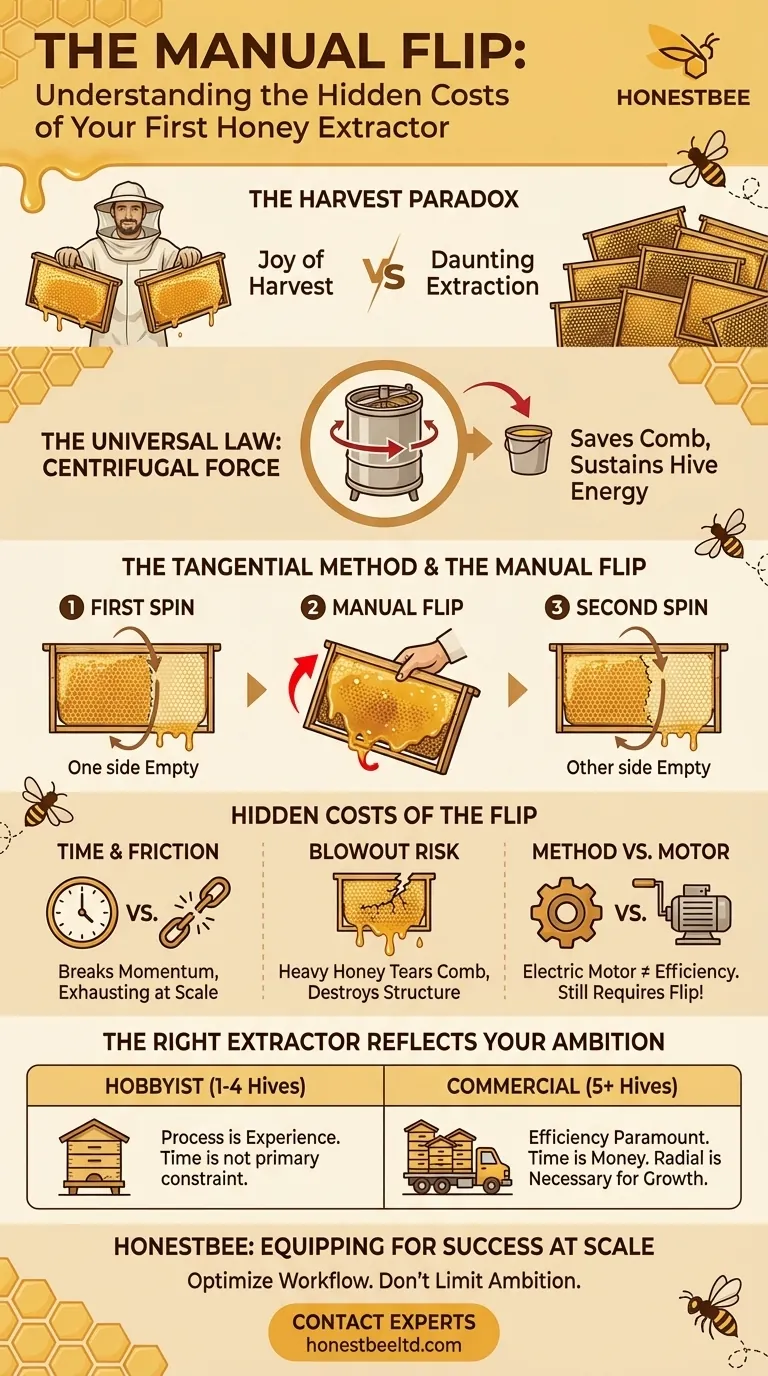

The Harvest Paradox

The honey harvest is a moment of triumph. Weeks of care, hive inspections, and patient observation culminate in frames heavy with golden, capped honey. But for many beekeepers, this success is immediately followed by a daunting physical reality: the extraction.

Suddenly, the sweet reward is locked behind a wall of labor. You're facing dozens, maybe hundreds, of frames. The romance of beekeeping gives way to the logistics of production. The single most important tool in this moment is your honey extractor, and the type you choose reveals more about the value of your time than you might think.

The Universal Law: Centrifugal Force

At its heart, every honey extractor is an elegant application of physics. It's a drum with a spinning cage designed for one purpose: to pull honey from the comb without destroying the delicate wax structure.

This is a profound partnership with the bees. By returning the empty, intact comb to the hive, you save the colony an immense amount of energy—the equivalent of many pounds of honey—that would be spent rebuilding. The extractor isn't just a tool for harvesting; it's a tool for sustaining the hive's efficiency.

The Tangential Method: A Study in Simplicity

The most common entry-point into extraction is the tangential extractor. Its design is beautifully simple. Frames are placed in the basket so that one flat side of the honeycomb faces outward, tangent to the circle of rotation.

The Two-Step Process

The operation is a rigid, two-act play:

- The First Spin: You spin the basket. Centrifugal force flings honey out, but only from the outward-facing side of the comb. The inner side remains full.

- The Manual Flip: You must stop the machine completely. You open the lid, and one by one, you remove each sticky frame, turn it around, and place it back in the basket.

- The Second Spin: You spin the machine again to empty the second side.

This manual flip is the defining characteristic of the tangential method. It's a simple solution, but it carries a hidden operational cost.

The Psychology of Interruption

While the simplicity of a tangential extractor is appealing, especially for its lower initial cost, the manual flip is a constant source of friction. Each stop-and-flip cycle breaks your momentum. For a small number of hives, it's a manageable, even meditative, part of the craft.

But as your apiary grows, this interruption becomes a significant bottleneck. The time and physical energy spent flipping frames compound with every box you need to process. What was once a simple task becomes a long, sticky, and exhausting day. The "cheaper" tool starts costing you your most valuable asset: time.

The Physics of a "Blowout"

There's also a mechanical risk. A frame full of honey is heavy. When you spin a tangential extractor, all the force is applied to one side of the comb while the other side bears the full weight of its honey.

Spin too fast on the first run, and the sheer weight of the honey on the inner side can rip the delicate wax comb apart from its foundation. This is known as a "blowout," and it destroys the very structure you were trying to preserve.

Choosing Your Tool: Method vs. Motor

It's crucial to separate the extraction method from the power source.

- Method (Tangential): This refers to how the frames are positioned and the need to flip them.

- Power (Manual vs. Electric): This refers to what spins the basket—a hand crank or a motor.

An electric motor can save your arm from fatigue and provide consistent speed, but it does not solve the fundamental inefficiency of the tangential method. You still have to stop, open, and flip every single frame.

The Right Extractor Reflects Your Ambition

Choosing an extractor isn't just a technical decision; it's a strategic one based on the scale of your operation.

| Scale of Operation | Recommended Approach | Key Consideration |

|---|---|---|

| Hobbyist (1-4 Hives) | Manual or Electric Tangential | The process is part of the experience. Time is not the primary constraint. |

| Commercial (5+ Hives) | Advanced (e.g., Radial) | Efficiency is paramount. The time lost flipping frames is a direct financial and operational cost. |

For small-scale beekeepers, the tangential extractor is a perfect, cost-effective starting point. It teaches the fundamentals of extraction and serves its purpose well.

For commercial apiaries and distributors, however, time is money. Every hour spent on labor is an hour not spent on other critical tasks. At this scale, the operational drag of a tangential system becomes unsustainable. The efficiency gained by moving to a system that extracts from both sides of the frame at once (like a radial extractor) is not a luxury—it's a necessity for growth.

At HONESTBEE, we focus on equipping commercial beekeepers for success at scale. We understand that the right equipment isn't about getting the job done; it's about optimizing your entire workflow. Your ambition shouldn't be limited by your tools.

If you're ready to move beyond the manual flip and build a more efficient honey harvesting operation, we can help you select the right equipment. Contact Our Experts

Visual Guide

Related Products

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

Related Articles

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- How to Harvest Honey Efficiently While Protecting Bee Health

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- The Extractor's Dilemma: Why Honey Extraction is More Than Just a Spin