The Moment of Truth in the Honey House

Inside every honey house, there is a moment of controlled violence. A frame, heavy and dripping with capped honey, is slotted into an extractor. The machine hums to life, and the immense weight begins to spin, accelerating until it becomes a blur.

This is the single greatest point of mechanical stress in the entire beekeeping year.

And in this moment, a single, fundamental choice made months earlier determines the outcome: a clean, efficient harvest, or a catastrophic "blowout"—a sticky, costly mess of destroyed comb and lost labor. That choice is the foundation.

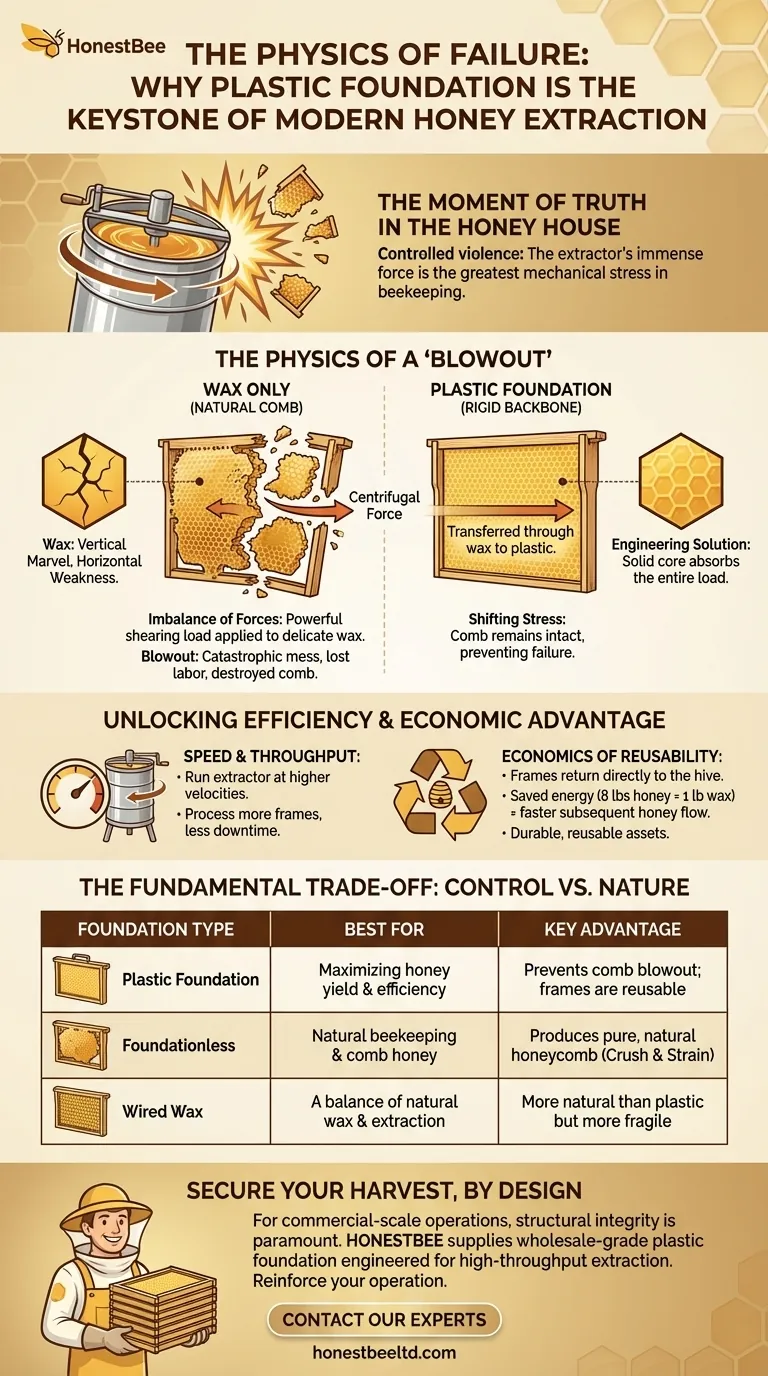

The Physics of a 'Blowout'

To understand the solution, we must first respect the problem. The forces at play inside an extractor are immense and unforgiving.

An Imbalance of Forces

A full frame of honey is a dense, heavy object. As the extractor spins, centrifugal force pulls that mass outward, away from the frame's center. This force isn't gentle; it's a powerful, shearing load applied directly to the delicate architecture of the honeycomb.

Wax: A Vertical Marvel, A Horizontal Weakness

Beeswax is an engineering miracle. It's optimized for incredible vertical compressive strength, allowing bees to stack pounds of honey and brood in a gravity-defying structure.

However, it was never designed to withstand the horizontal, tearing forces of a centrifuge. Especially on a warm day when the wax is more pliable, the structure simply gives way. The comb detaches from the frame, and the harvest is compromised. Psychologically, it's the feeling of trusting a material beyond its design limits—and watching it fail.

The Engineering Solution: A Rigid Backbone

Plastic foundation is not just a support; it's an elegant engineering answer to the inherent weakness of wax under specific stress. It re-engineers the physics of the frame itself.

Shifting the Point of Stress

The plastic sheet serves as a solid, non-negotiable core. Bees build their wax cells directly onto this rigid surface.

When the frame spins, the centrifugal force is transferred through the fragile wax and onto the durable plastic backbone. The plastic absorbs the entire load, a task for which it is perfectly designed. The comb, no longer bearing the critical stress, remains completely intact.

Unlocking Speed and Operational Efficiency

By eliminating the risk of a blowout, you remove the speed limit on your extraction.

You can run your extractor at much higher velocities, dramatically increasing the efficiency and throughput of your honey harvest. For a commercial apiary, this means processing more frames in less time, reducing labor costs and operational downtime.

The Economics of Reusability

After extraction, frames with plastic foundation can be returned directly to the hive. This is a crucial economic advantage.

The bees do not need to expend enormous energy rebuilding the comb from scratch (a process that consumes roughly 8 pounds of honey to produce 1 pound of wax). This saved energy translates directly into a faster, more productive subsequent honey flow. The frame becomes a durable, reusable asset rather than a single-use consumable.

The Fundamental Trade-Off: Control vs. Nature

Of course, plastic foundation is a choice that prioritizes durability and efficiency. It's essential to understand the alternatives as a conscious trade-off.

| Foundation Type | Best For | Harvesting Method | Key Advantage |

|---|---|---|---|

| Plastic Foundation | Maximizing honey yield & efficiency | High-speed centrifugal extractor | Prevents comb blowout; frames are reusable |

| Foundationless | Natural beekeeping & comb honey | Crush and Strain (destructive) | Produces pure, natural honeycomb |

| Wired Wax | A balance of natural wax & extraction | Low-speed, careful extraction | More natural than plastic but more fragile |

- For Maximum Yield: If your operation is geared toward maximizing honey production with peak efficiency, plastic foundation is the superior choice. Its durability is purpose-built for high-speed mechanical harvesting.

- For Natural Comb: If the goal is pure comb honey or a more naturalistic approach, foundationless frames are ideal, accepting the "crush and strain" method as the means of harvesting.

Secure Your Harvest, by Design

For any commercial-scale operation, where predictability, durability, and efficiency are paramount, managing the physics of the harvest isn't a luxury—it's the core of the business. The structural integrity provided by a robust foundation is the difference between a secure yield and a preventable failure.

At HONESTBEE, we supply commercial apiaries with the wholesale-grade plastic foundation engineered to withstand the demands of high-throughput extraction. We provide the critical backbone your operation needs to eliminate blowouts, maximize speed, and ensure your frames become long-term, productive assets. To reinforce your operation at its most critical point, Contact Our Experts.

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Related Articles

- Wooden vs. Plastic Bee Hive Frames: Balancing Sustainability and Practicality

- The Beekeeper's Dilemma: Choosing Between Wooden Frame Ideals and Plastic Frame Efficiency

- The Pragmatic Hive: Engineering Resilience with Wood Frames and Plastic Foundation

- Plastic vs. Wax Foundations: A Data-Driven Guide for Beekeeping Success

- Plastic vs. Beeswax Foundations: What Beekeepers Need to Know for Sustainable Hives