The air in the honey house is thick and sweet, but all you feel is the mounting pressure. A mountain of honey-filled supers waits, while your shoulder aches from wrestling a cold knife through yet another frame of stubborn beeswax. Each pass is a grind. You glance at the clock, then back at the stacks of unprocessed frames. At this pace, the harvest will drag on for days, maybe even weeks. This isn't just hard work; it's a bottleneck that grinds your entire operation to a halt.

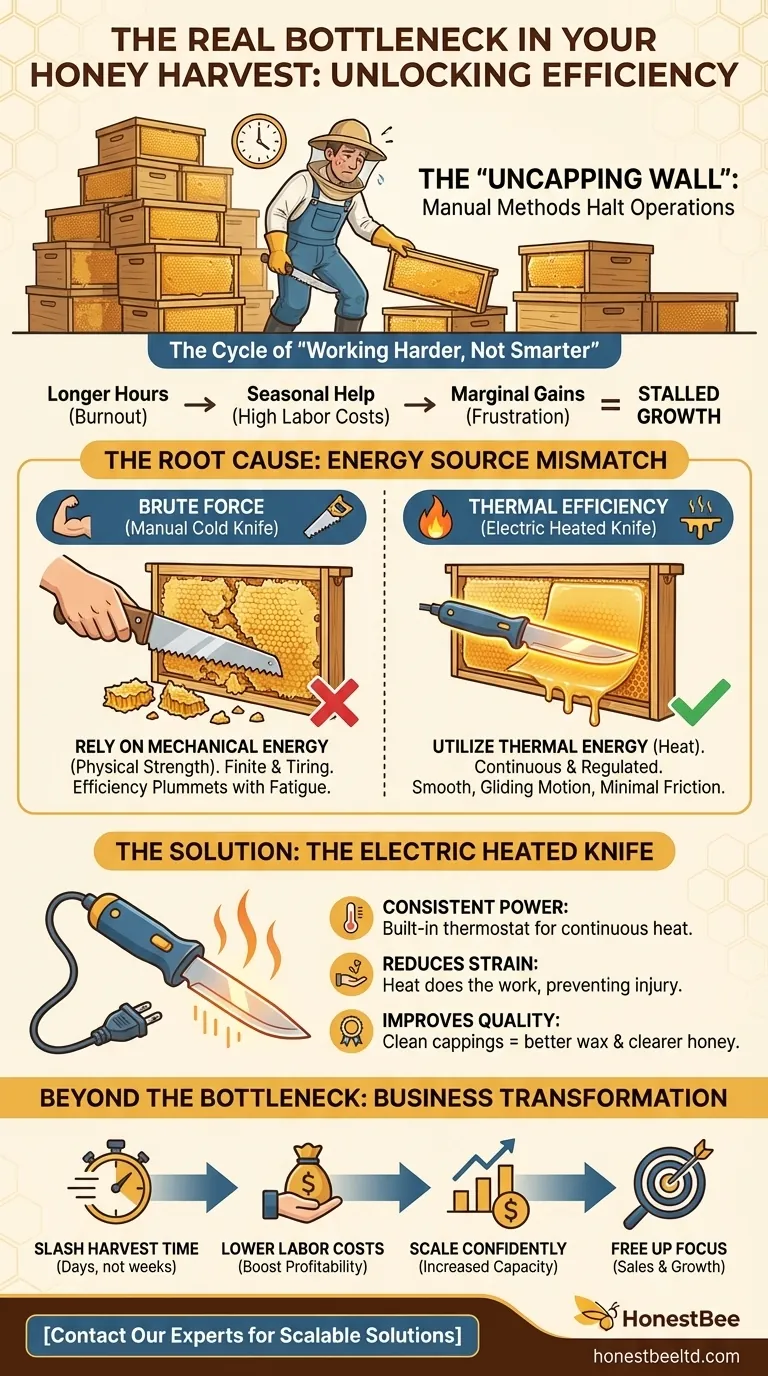

The Cycle of "Working Harder, Not Smarter"

If this scene feels familiar, you're not alone. Many commercial beekeepers hit this "uncapping wall" as their apiary grows. The tools that worked perfectly for two or three hives become an exhausting liability at twenty, fifty, or a hundred.

In response, you do what any dedicated business owner would: you try to muscle through it.

- You try working longer hours, leading to burnout during the most critical season of the year.

- You hire seasonal help, but the slow, manual process drives up labor costs and eats directly into your profit margin per pound of honey.

- You try simple tricks like dipping a cold knife in hot water, but the marginal gains are quickly lost, and the frustration remains.

This isn't just an inconvenience; it has serious business consequences. A slow harvest means delayed deliveries to customers, missed opportunities at farmers' markets, and a compressed timeline for preparing your hives for the next season. The bottleneck isn't just in the honey house—it's constricting your business's potential for growth and profitability.

The Real Culprit: It's Not Your Effort, It's Your Energy Source

For years, we've treated uncapping as a test of endurance. But what if the problem isn't your effort? What if the issue is a fundamental mismatch in physics?

The core problem lies in how your tool removes the wax cappings.

Brute Force vs. Thermal Efficiency

A manual cold knife, scratcher, or roller relies entirely on mechanical energy—your physical strength—to saw, scrape, or puncture the wax. This requires immense, repetitive effort. As you tire, you slow down, and your efficiency plummets. You are the only power source, and that source is finite.

An electric heated knife, however, introduces a completely different energy source: thermal energy. The heated blade doesn't just cut the wax; it melts its way through with minimal friction. The heat does the heavy lifting, transforming the task from a high-effort struggle into a smooth, gliding motion.

The "solutions" of working harder or dipping a knife in hot water fail because they are temporary, inefficient applications of energy. They treat the symptom—stubborn wax—without addressing the root cause: relying on a limited energy source (your body) for a large-scale industrial task.

The Right Tool for the Right Job: The Electric Heated Knife

To solve an energy bottleneck, you need a tool designed to deliver the right kind of energy consistently and effectively. For commercial-scale uncapping, that tool is the electric heated knife.

It’s not just "another option"; it is the physical embodiment of the thermal efficiency principle. It was engineered to solve the exact problems that arise when an apiary scales up.

- It tackles the root cause directly: The built-in thermostat provides continuous, regulated heat, ensuring the blade glides through the last frame of the day as easily as the first. It replaces inconsistent physical effort with reliable thermal power.

- It dramatically reduces physical strain: By letting heat do the work, you conserve your energy, reduce the risk of repetitive strain injuries, and maintain a consistent pace without fatigue.

- It improves product quality: The clean, melting action removes cappings in neat sheets, making them easier to collect and render into valuable, clean beeswax. This also means fewer fine wax particles end up in your honey, simplifying your filtering process.

Beyond the Bottleneck: What a Streamlined Harvest Unlocks for Your Business

When you remove the uncapping bottleneck, you don't just save time; you create new opportunities. The efficiency gained radiates throughout your entire operation.

Suddenly, you can:

- Slash your harvest time, turning a week-long ordeal into a focused, two-day process.

- Significantly lower your labor costs, boosting the profitability of every jar of honey you sell.

- Scale your apiary confidently, knowing that your processing capacity can keep up with increased production.

- Free up your time and energy to focus on sales, developing new products, or expanding your distribution channels.

For beekeeping equipment distributors, providing your clients with a clear path to this level of efficiency isn't just about selling a tool; it's about offering a strategic upgrade that directly impacts their bottom line and solidifies your role as an essential partner in their success.

Solving the uncapping problem isn't just about a faster harvest. It's about building a more resilient, profitable, and scalable beekeeping business. Our team understands the unique challenges commercial apiaries face, and we specialize in supplying the robust, reliable equipment needed to overcome them. If you're ready to break through your operational bottlenecks and unlock your apiary's true potential, let's talk about the right tools for your scale. Contact Our Experts

Visual Guide

Related Products

- Professional Extra-Wide Uncapping Fork with Bent Tines for Beekeeping

- Extra Wide Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

- Stainless Steel Double Sided Honey Uncapping Fork with Scraper

- Wide Adjustable Stainless Steel Honey Uncapping Fork with Scraper

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

Related Articles

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- The Unseen Geometry of the Honey Harvest: Why Your Uncapping Tool Fails

- How Beekeepers Can Maximize Honey Yield and Beeswax Quality from Cappings

- The Extractor's Bottleneck: Why Your Uncapping Tank Defines Your Harvest

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability